»What challenges does industry face?« This was the central question guiding the »Research and Development Trends« issue as we discussed future technology and innovation needs in manufacturing with executives from a variety of industries. Despite industry-specific differences, the overall result was homogeneous: The manufacturing of the future is data-driven, but there is still a lot of development work to be done to get there.

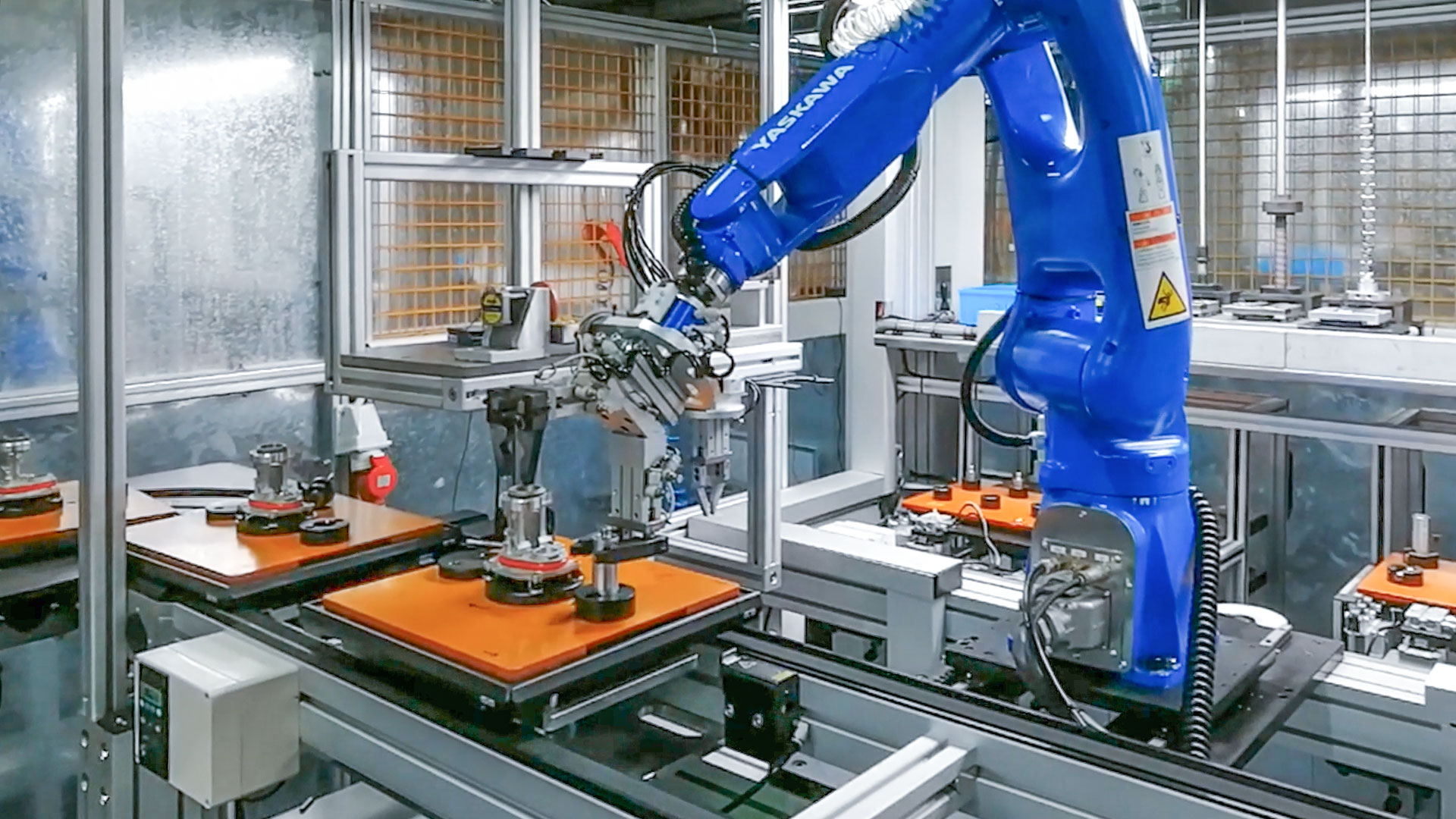

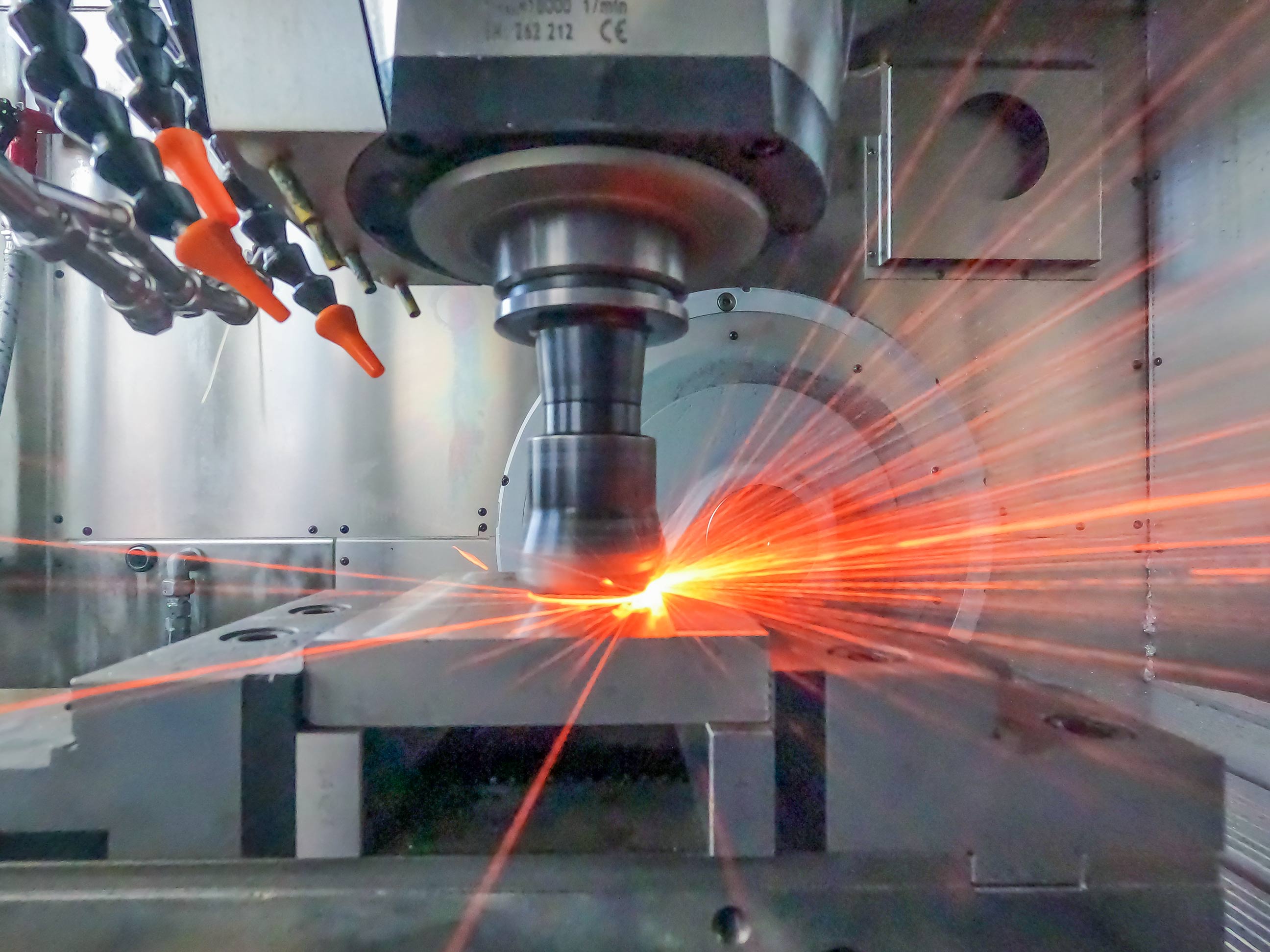

This time, we switch perspectives: We invite you to look over our shoulders and see us at work. We present R&D projects and solutions which provide answers to industry’s most pressing questions. We will show you how our researchers transfer digital, networked technologies into industrial applications, how they curate large amounts of data using machine learning and artificial intelligence, and how they develop applications on this basis.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology