Automated dirt removal with AI and industrial robots

At Parts2Clean 2022, Fraunhofer IPK will demonstrate how intelligent image processing can contribute to maintaining capital goods. AI-based component and dirt detection in combination with innovative robotics and CO2 cleaning technologies enables the automation of maintenance process chains.

Maintenance is a dirty business to begin with: Component contamination must be monitored, and when a certain “dirt level“ is reached, intervention, i.e. cleaning, is required. Researchers at Fraunhofer IPK have developed a technology that uses AI methods such as machine learning and deep learning to automatically monitor and determine the soiling degree of components. Pixel-precise segmentation of image data enables to diagnose the extent of surface contamination and to plan cleaning in a targeted manner. In this context, the contamination degree is not only decisive for the timing of cleaning. Process parameters such as the quantity and type of cleaning agents used can also be optimized.

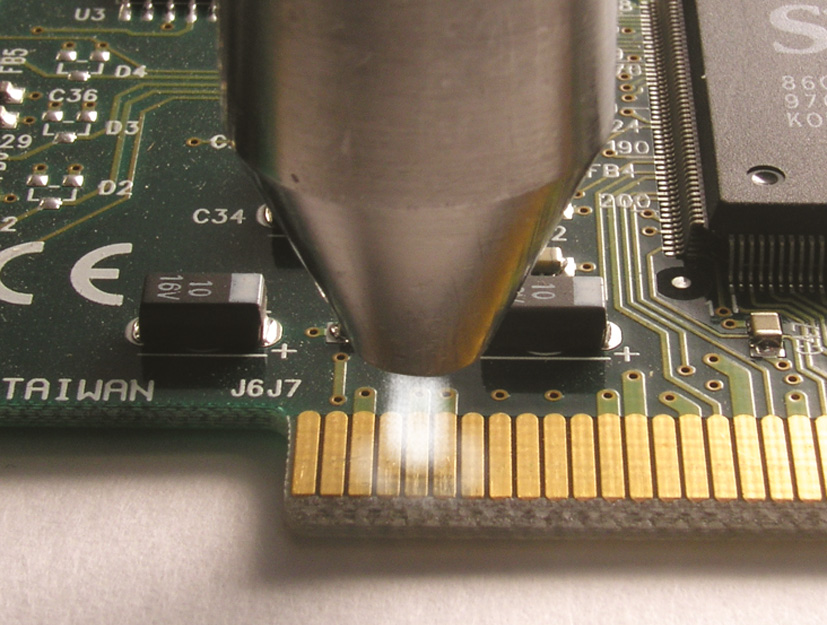

To automate the actual cleaning process, Fraunhofer IPK relies on CO2-based cleaning technologies as well as robot-assisted machining. Blasting with solid carbon dioxide is an environmentally neutral alternative to conventional cleaning processes. Solid CO2 is applied at high speed to the surface to be cleaned. Not only do mechanical effects produce the cleaning effect, but the low temperatures also achieve a thermal effect. To guide the blasting process, researchers at Fraunhofer IPK use industrial robots. Robots have “learned“ a lot in recent years: Thanks to modern force control and new solutions for human-robot cooperation, they have evolved into universal and even mobile processing and assembly machines. This makes results more reproducible and reduces the workload of employees.

Visit us at the booth of the Fraunhofer-Business Area Cleaning:

Hall 4, booth B20

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology