Fraunhofer IPK at EMO 2025

We Live Sustainability: Energy Monitoring and Digital Product Assistance

Wherever the machine tool music plays, we are there: From September 22 to 26, 2025, Fraunhofer IPK will be presenting solutions at EMO in Hannover together with the IWF of the Technische Universität Berlin. In the Sustainability Area of the VDW – Verein Deutscher Werkzeugmaschinenfabriken e.V. (German Machine Tool Builders' Association), we will be showcasing energy monitoring and digital assistance for production personnel.

Digital production assistance makes all things clear on the shop floor

Demands placed on shop floor employees are higher than ever before. While current machine generations are increasingly complex to operate, quality requirements for manufacturing results are also rising. At the same time, it is becoming more difficult for companies to find suitable personnel for manufacturing. Many companies therefore work with international teams, career changers, or temporary workers.

Digital assistance systems are a promising approach to achieving optimal production performance under these conditions. These systems provide information in real time, including data and instructions, so that it is quickly available and non-value-adding activities in production are reduced. This improves interaction between humans and machines and reduces the amount of training required. Since the information in the systems can theoretically be translated into any language, language barriers are reduced. Overall, efficiency, quality, and safety in production are improved because error-free execution of work steps is supported.

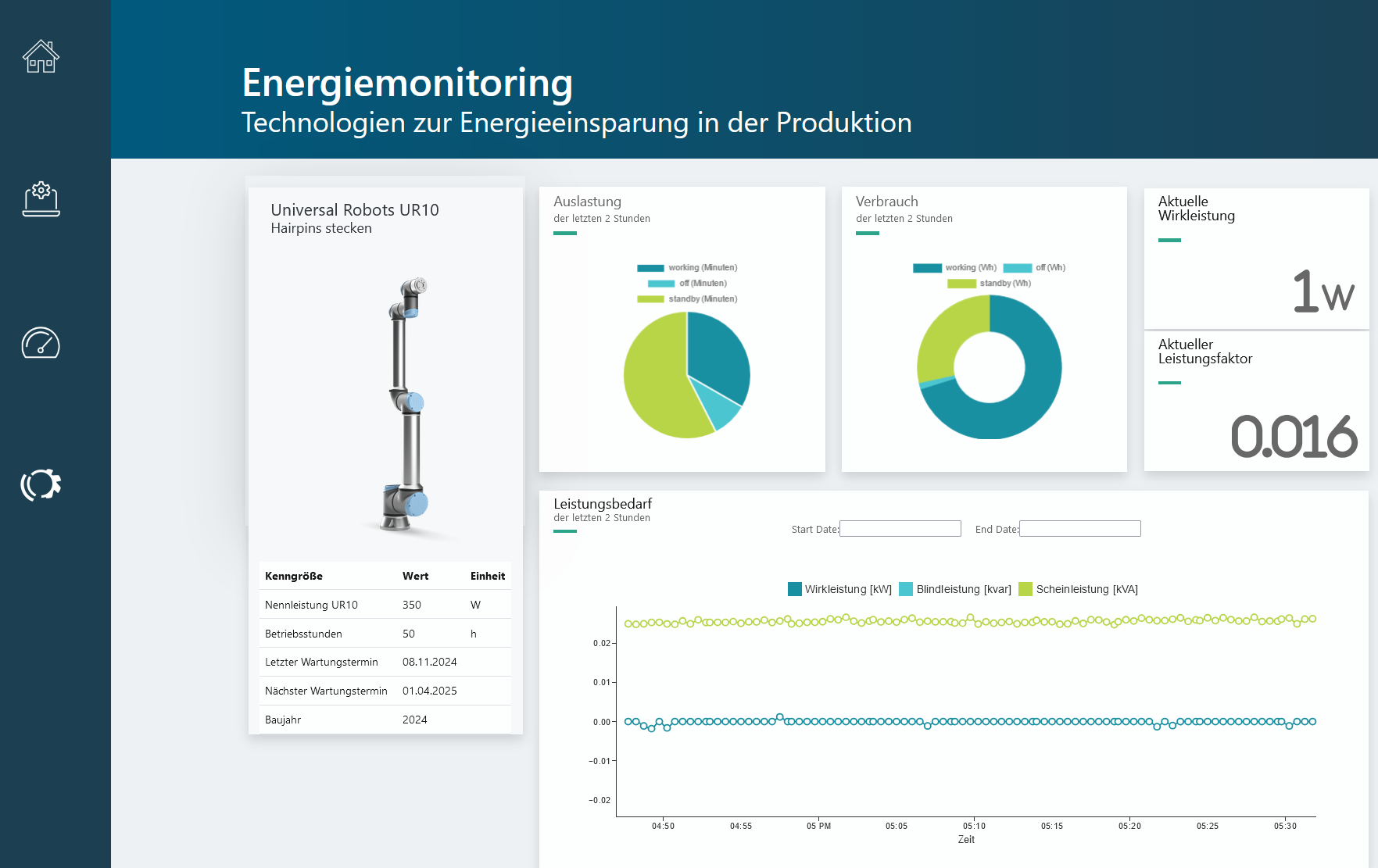

Energy monitoring for efficiency in production

In order to achieve the climate targets set by Germany and the EU, manufacturing processes in the manufacturing industry must be made as energy-efficient as possible. However, detailed monitoring of energy consumption required to achieve this poses challenges for companies: Numerous individual consumers and production steps must be taken into account in the process chains, and the energy requirements of individual consumers cannot always be determined transparently. Older systems in particular are often not equipped with component-specific energy measurement systems.

Fraunhofer IPK equips both old and new production systems with energy measurement systems capable of precisely recording the energy consumption of individual components. This results in IoT-based monitoring that provides transparency about energy consumption in individual process steps. On this basis, companies can take targeted measures to reduce energy consumption and optimize resource utilization. This not only enables them to meet legal requirements, but also makes production more efficient and thus more cost-effective.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology