Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2026 |

Digital Twin for Automated Post-processing Chain in Additive Manufacturing

Nguyen, Sissy-Linh; Ahmed, Omnya; Joost, Robert; Lünnemann, Pascal; Larusch, Terence |

Konferenzbeitrag

Conference Paper

|

| 2025 |

Challenges and Lessons Learned for Industry Transfer of DPP Solutions

Manoury, Marvin Michael; Wiesner, Malina; Riedelsheimer, Theresa; Honsberg, Finn; Lindow, Kai |

Konferenzbeitrag

Conference Paper

|

| 2025 |

3D Data Integration in the Digital Twin for Circular Economy

Stollenwerk, Matthias; Joost, Robert; Riedelsheimer, Theresa; Lindow, Kai |

Zeitschriftenaufsatz

Journal Article

|

| 2025 |

From Stakeholder Needs to Secure Digital Twin Services: Critical Infrastructure Use Cases within the INTACT Framework

Burdulea, Ilinca-Laura; Gogineni, Sonika; Kostopoulos, Stamatios; Markakis, Evangelos K.; Manganaris, Kyriakos N.; Lazarakis, Fotis I. |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Energieeffizienzsteigerung mit IoT-basiertem Monitoringsystem

Uhlmann, Eckart; Polte, Julian; Geisert, Claudio |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Digital Twins within the Circular Economy: Literature Review and Concept Presentation

Mügge, Janine; Seegrün, Anne; Hoyer, Tessa-Katharina; Riedelsheimer, Theresa; Lindow, Kai |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Developing Digital Twins for energy efficiency in the production phase of products

Wehking, Sebastian; Riedelsheimer, Theresa; Tanrikulu, Cansu; Lindow, Kai |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Sustainable Product Lifecycle Management - Implementation of a Digital Twin of a Biologically Transformed Product-Ecosystem

Wehking, Sebastian; Seegrün, Anne; Riedelsheimer, Theresa; Lindow, Kai |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

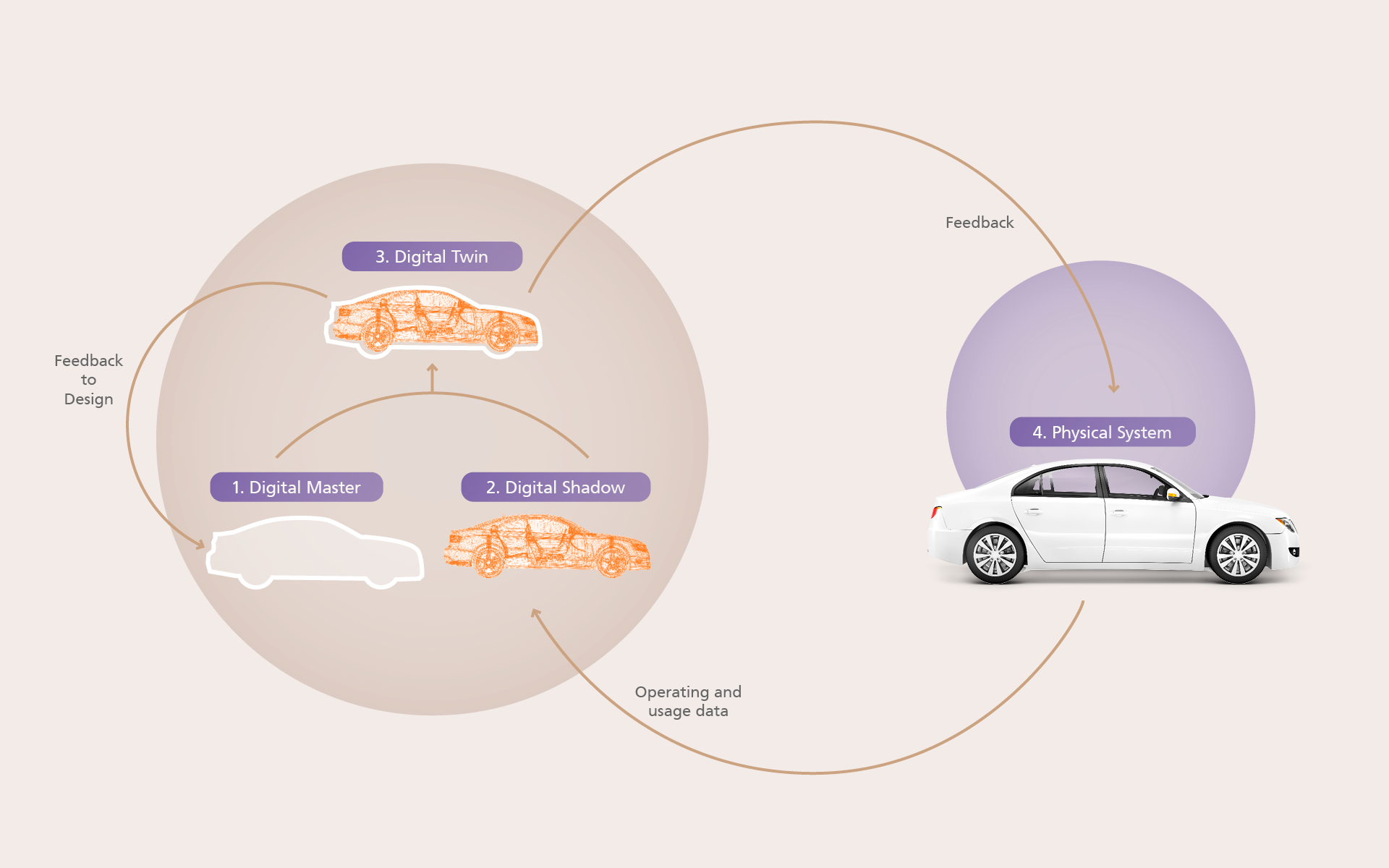

Was macht einen digitalen Zwilling aus?

Lindow, Kai; Tanrikulu, Cansu |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Konzeption eines digitalen Zwillings für die Produktentstehung in der Luftfahrtindustrie

Brünnhäußer, Jörg; Jurczok, Christoph; Zimmermann, Thomas; Larusch, Terence; Kenfack Zangue, Renaud; Böhnke, Jacob; Lünnemann, Pascal; Lindow, Kai |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Concept for a modular system model for energy-efficiency monitoring of factory supply systems

Sigg, Stefan; Thiele, Gregor; Trapp, Marvin; Krüger, Jörg |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Value co-creation through digital twins in decentralized data ecosystems

Tanrikulu, Cansu; Berg, Henning; Konietzko, Erik Paul; Rosa Cencic, Maiara; Lindow, Kai |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Developing Digital Twins for Smart Product-Service Systems:A Methodical Approach Demonstrated with a Fuel Cell Use Case

Kenfack Zangue, Renaud; Gogineni, Sonika; Geisert, Claudio |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Sustainable product lifecycle management with Digital Twins: A systematic literature review

Seegrün, Anne; Kruschke, Thomas; Mügge, Janine; Hardinghaus, Louis; Knauf, Tobias; Riedelsheimer, Theresa; Lindow, Kai |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Digital Twin for Circular Economy

Mügge, Janine; Riedelsheimer, Theresa; Lindow, Kai |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Implementing digital twins in existing infrastructures

Lünnemann, Pascal; Lindow, Kai; Goßlau, Leo |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Smarte Überwachung elektrischer Großantriebe

Geisert, Claudio; Polte, Julian; Uhlmann, Eckart; Rauch, Hartmut; Brach, Karsten |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

End-of-life decision support to enable circular economy in the automotive industry based on digital twin data

Mügge, Janine; Hahn, Inka Rebekka; Riedelsheimer, Theresa; Chatzis, Johannes; Boes, Joachim |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Blue Print Plant Model. Ein Modell zur Unterstützung des Fabrikplanungsprozesses

Lange, Annika; Ihnen, Deike Magret; Knothe, Thomas |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

The Digital Twin for Operations, Maintenance, Repair and Overhaul

Lünnemann, Pascal; Fresemann, Carina; Richter, Friederike |

Aufsatz in Buch

Book Article

|

| 2023 |

Empowering End-of-Life Vehicle Decision Making with Cross-Company Data Exchange and Data Sovereignty via Catena-X

Mügge, Janine; Große Erdmann, Julian; Riedelsheimer, Theresa; Manoury, Marvin Michael; Smolka, Sophie Odette; Wichmann, Sabine; Lindow, Kai |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

F5G OpenLab: Enabling Twin Transition through Ubiquitous Fiber Connectivity

Balanici, Mihail; Shariati, Mohammad Behnam; Safari, Pooyan; Chojecki, Paul; Chemnitz, Philipp Axel Moritz; Przewozny, David; Fischer, Johannes; Freund, Ronald |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Project-Based Learning in Engineering Education - Developing Digital Twins in a Case Study

Hagedorn, Lisa; Riedelsheimer, Theresa; Stark, Rainer |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Smart Maintenance - Was ist das und was kann es?

Geisert, Claudio |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Digital Twins for Sustainability in the Context of Biological Transformation

Seegrün, Anne; Mügge, Janine; Riedelsheimer, Theresa; Lindow, Kai |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Resource efficient production of car body parts - implementation of digital twins across process chains

Weber, Joshua; Lemke, Josefine; Sunderkoetter, Christina; Haase, Patrick; Hoefemann, Matthias; Joos, Paul; Merklein, Marion |

Vortrag

Presentation

|

| 2022 |

A cognitive assistance system with augmented reality for manual repair tasks with high variability based on the digital twin

Eversberg, Leon; Ebrahimi, Puya; Pape, Martin; Lambrecht, Jens |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Harmonization of Heterogeneous Asset Administration Shells

Koutrakis, Nikolaos-Stefanos; Gowtham, Varun; Pilchau, W.B.P. von; Jung, T.J.; Polte, Julian; Hähner, J.; Corici, Marius-Iulian; Magedanz, Thomas; Uhlmann, Eckart |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

The Use of Digital Twins to Overcome Semantic Barriers in Hyperconnected Ecosystems for Industry

Jäkel, Frank-Walter; Gering, Patrick; Knothe, Thomas |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Application of Uncertainty-Aware Sensor Fusion in Physical Sensor Networks

Gruber, Maximilian; Pilar von Pilchau, Wenzel; Gowtham, Varun; Koutrakis, Nikolaos-Stefanos; Schönborn, Nicolas; Eichstädt, Sascha; Hähner, Jörg; Corici, Marius-Iulian; Magedanz, Thomas; Polte, Julian; Uhlmann, Eckart |

Konferenzbeitrag

Conference Paper

|

| 2022 |

Digital Twins for Circular Economy - Enabling Decision Support for R-Strategies

Mügge, Janine; Hahn, Inka Rebekka; Riedelsheimer, Theresa; Chatzis, Johannes |

Zeitschriftenaufsatz

Journal Article

|

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology