Intelligent decision support systems can help prevent sudden major disruptions caused by absences.

more info

Intelligent decision support systems can help prevent sudden major disruptions caused by absences.

more info

Without a plan and strategy, sustainability can cause considerable costs. A new in-house training program teaches concepts, methods and technical solutions alike.

more info

Steel as a sustainable lightweight material? What appears contradictory at first could revolutionize the design of battery housings for electric vehi-cles, making e-mobility even more eco-friendly.

more info

The ReTraNetz-BB real-world laboratory supports the local vehicle and supplier industry’s turnaround. Process chains are tested here and technologies are transferred into real-life scenarios.

more info

In volatile times, one thing matters more than ever: Both production and products must be safe and reliable. At the IWF of TU Berlin, industrial safety is addressed from many angles.

more info

Ready for digitalization in production? With the help of an AI-based learning platform, SMEs can prepare their employees for their individual roles in a digitally integrated production.

more info

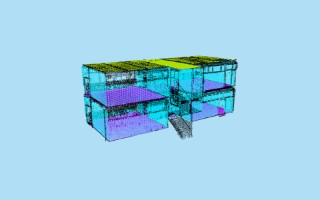

Existing buildings are responsible for one third of all carbon emissions in Germany. In order to renovate them efficiently on the basis of 3D models, the Scangineering process is being adapted.

more info

Many machining companies face the same dilemma. They collect process data during production, yet expertise for contextualizing and evaluating it is often missing. Triggered sensors can help.

more info

Generative AI is revolutionizing the way we interact with knowledge. How can companies take advantage of this development to manage their domain knowledge?

more info

Keeping emissions in focus: Benchmarking greenhouse gas emissions enables quick comparisons of sustainable business developments.

more info