Hybrid laser arc welding and narrow-gap submerged-arc welding increase efficiency when welding components with wall thicknesses greater than 50 mm

The hybrid laser arc welding technology is increasingly proving to be an innovative alternative to other welding methods.

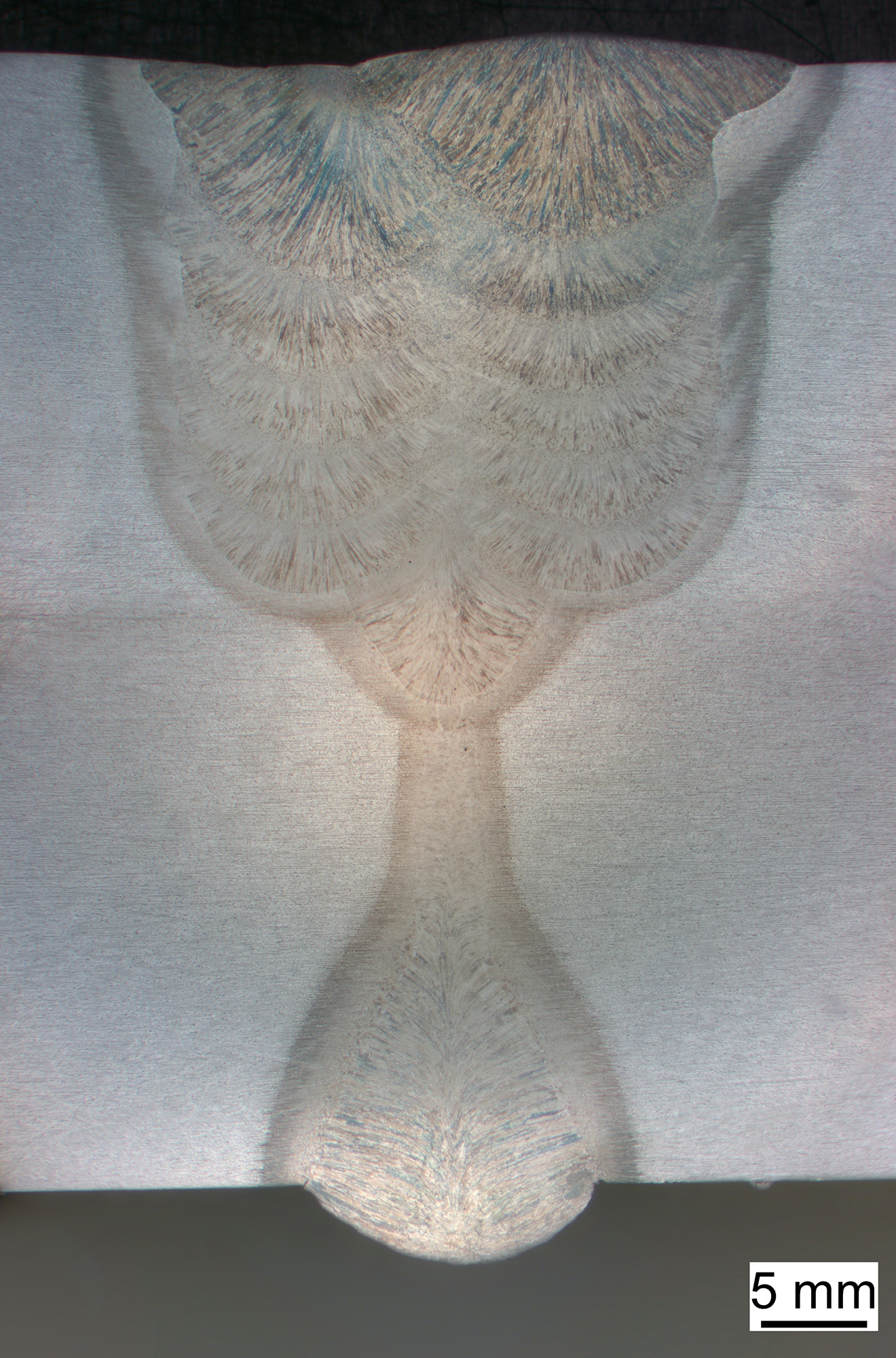

Researchers at Fraunhofer IPK are developing a new process in which the efficient high-power hybrid laser arc welding method can be used in combination with narrow-gap submerged-arc welding to join thick-walled structures.

The combination of the two welding methods reduces manufacturing time and increases profitability while improving quality and the competitiveness of many SMEs. Productivity in the manufacture of towers for wind turbines is also significantly improved.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology