Innovative post-processing and material development for sustainable production

Fraunhofer IPK at Formnext 2025

From November 18 to 21, 2025, Fraunhofer IPK will be presenting its latest developments in the field of additive manufacturing at Formnext 2025 in Frankfurt. The focus will be on post-processing and the processing of demanding materials. Innovative solutions for electron beam melting (EB-PBF) of materials that are difficult to weld, as well as the cold spray process for coating hard materials and copper are at the center of attention.

Visit us at FormNext in hall 11.1, booth D31.

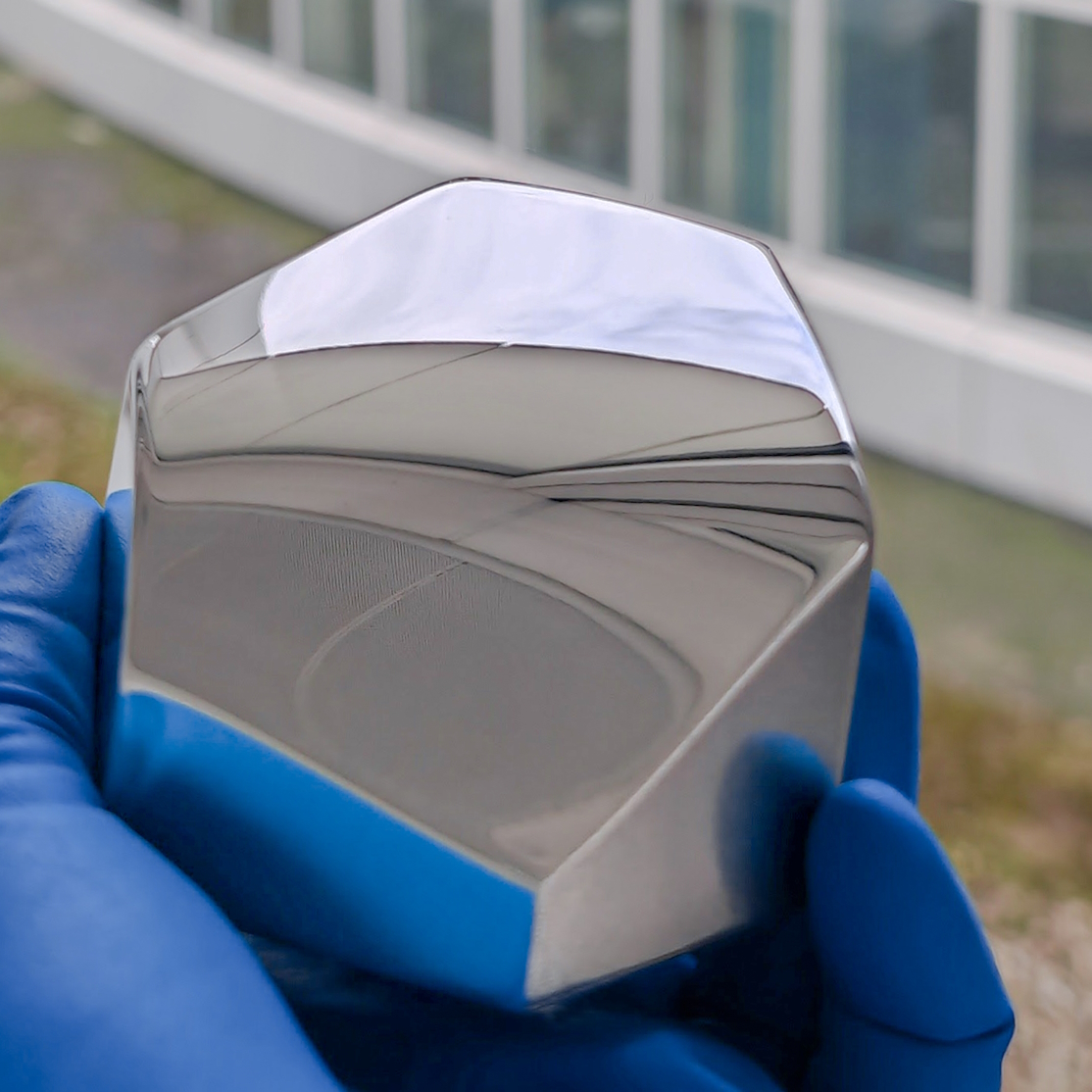

Post-processing: Efficient surface finishing for medical technology and the jewelry industry

In the fields of medical technology and jewelry manufacturing, post-processing is a crucial phase that significantly determines the quality and value of the end product. Traditionally, many of these post-processing steps are manual, resulting in long throughput times and varying results. We develop automated manufacturing processes for you that are specifically designed for complex free-form geometries. This allows high-gloss surfaces to be achieved with maximum precision and reproducibility – and in significantly less time than before.

Our solutions not only reduce manual effort, but also increase your competitiveness through more efficient production processes. Especially in sensitive industries such as medical technology, automated post-processing procedures ensure consistently high product quality while complying with strict standards. In the jewelry industry, these innovative processes open up new design possibilities for perfectly finishing filigree and sophisticated designs. Benefit from our expertise in developing customized manufacturing processes that make your production future-proof and sustainable.

EB-PBF for materials that are difficult to weld

Processing difficult-to-weld materials using electron beam powder bed fusion (EB-PBF) poses a major challenge, particularly in the energy technology, tool manufacturing, and aerospace industries. Due to their complex alloy composition and thermal properties, these materials can often only be processed to a limited extent or not at all using laser powder bed fusion (L-PBF). As a leading research and development partner, we support you in developing customized manufacturing processes and comprehensive material qualification for EB-PBF.

Through our application-oriented research, we enable you to use new materials with improved mechanical and thermal properties that also offer significant weight savings. This allows you to benefit from sustainable production solutions that strengthen your competitiveness in the long term. Our interdisciplinary technology transfer ensures seamless integration into your production facilities and guarantees the highest quality and process stability – even with the most demanding materials. Trust in our expertise to optimally exploit the potential of the EB-PBF process for your individual requirements.

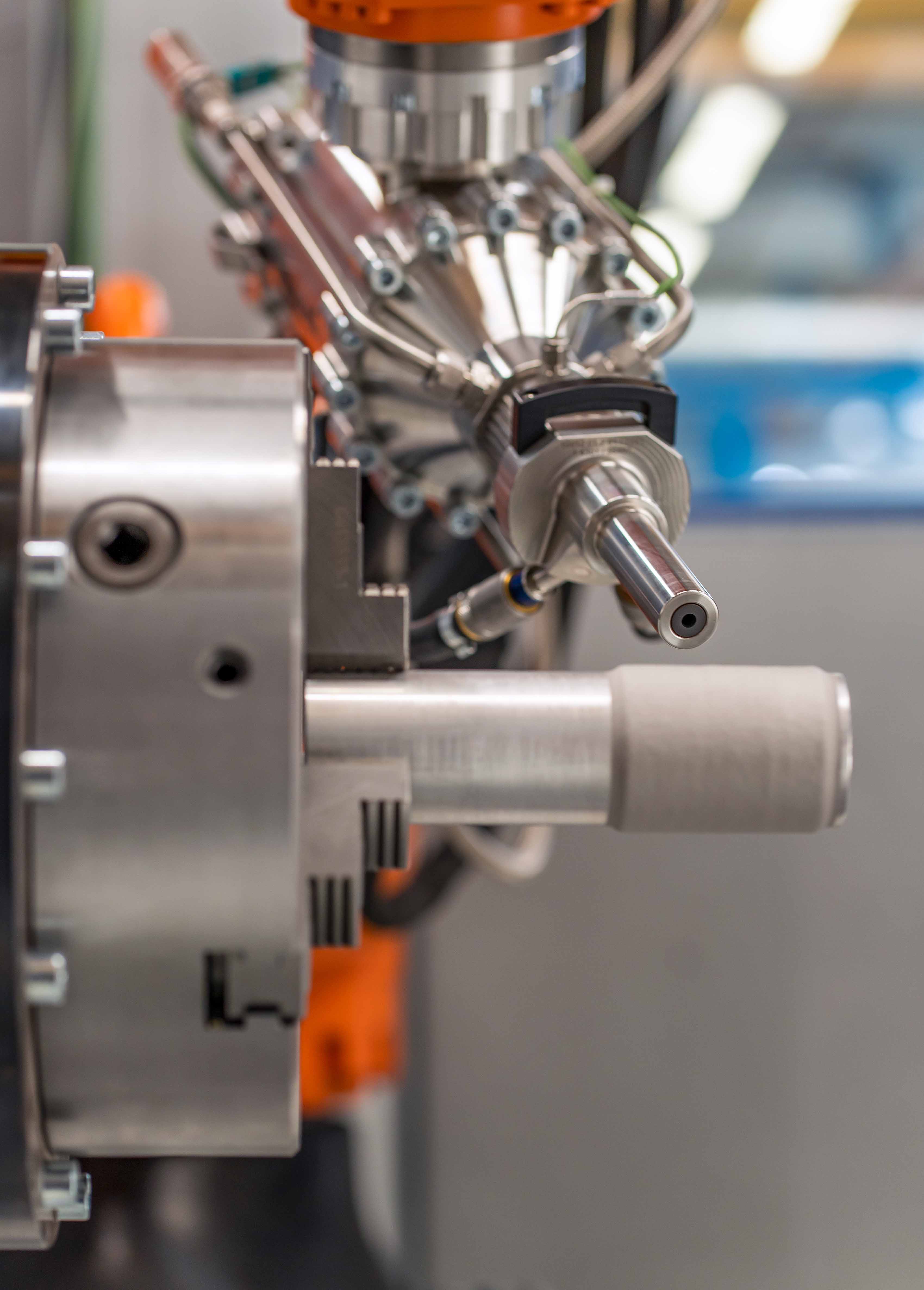

Cold spray using hard materials and copper

Applying cold spray processes offers groundbreaking opportunities for processing non-weldable materials and material combinations, particularly for industries such as oil and gas, pump and hydraulic manufacturers, and agricultural technology. Cold spray processes accelerate the material onto the substrate surface at high speed without significant heat input. This enables the production of coatings made of hard materials and copper, which otherwise could not be bonded due to their thermal sensitivity or different melting points.

We support you by developing customized manufacturing processes and comprehensive material qualifications to achieve optimal results. You benefit from reduced thermal deformation and stress in the component, as well as increased product life thanks to innovative material combinations. Cold spray opens up new potential for improving your manufacturing processes and competitiveness, especially in demanding applications where wear resistance and corrosion protection are essential. Trust in our expertise as a reliable development partner for sustainable production solutions in this highly specialized field of technology.

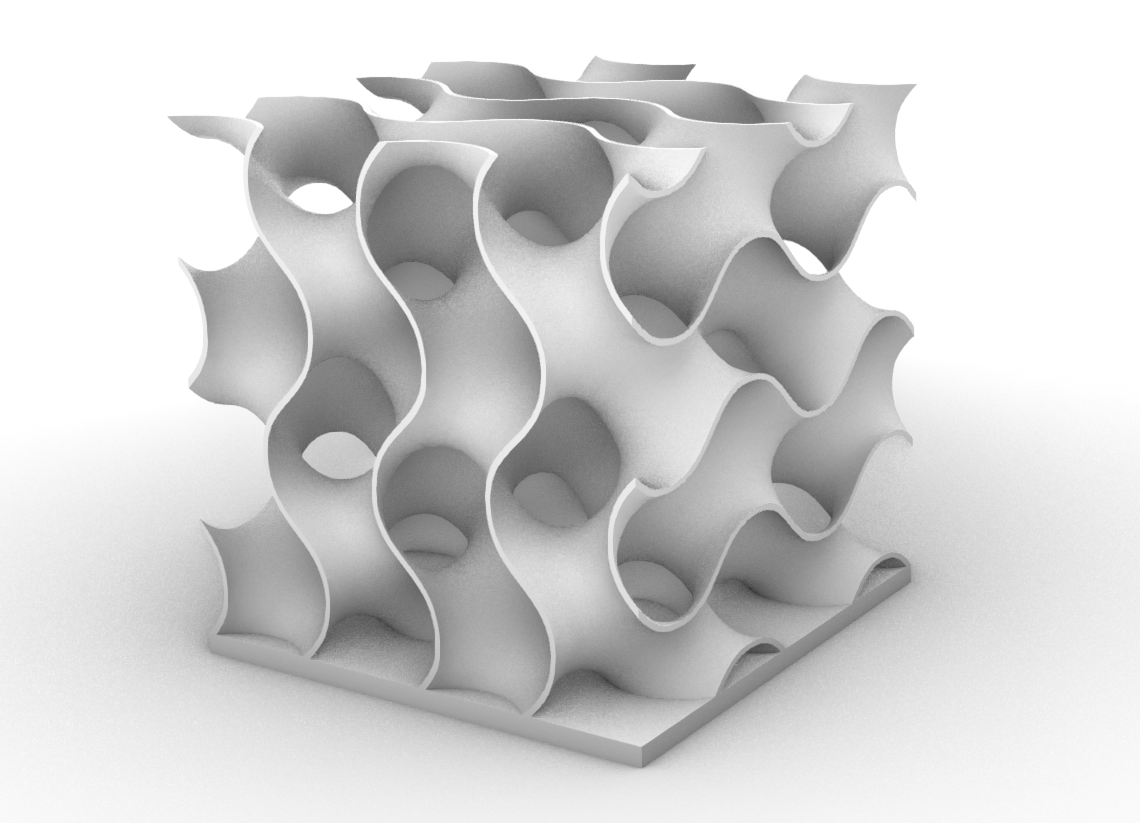

Additive manufacturing of heat exchangers

Additive manufacturing (AM) opens up new perspectives in the development and production of heat exchangers, especially for the automotive, heating technology, and aerospace industries. Traditional plate heat exchangers often reach their limits when it comes to increasing efficiency and reducing weight. By using modern simulation techniques and innovative design methods, at Fraunhofer IPK we can develop complex heat exchanger structures that enable significantly improved heat transfer. Additive manufacturing makes it possible to produce optimized geometries with fine channels and individual flow paths that cannot be achieved with conventional methods.

This leads to a significant increase in efficiency while reducing material usage and weight – advantages that are particularly crucial in the aerospace and automotive sectors. You benefit from a sustainable solution that not only lowers your production costs but also helps increase your competitiveness. Our application-oriented research and development supports you in creating digital twins of your heat exchangers and precisely simulating their performance under real-world conditions. Together, we can ensure sustainable and resource-efficient production technology.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology