Combination of two welding processes for thick plates: laser hybrid and narrow-gap submerged-arc welding

With this process variant, high sheet thicknesses can be welded with a lower number of layers and lower heat input.

Hybrid laser arc welding technology is increasingly proving to be an innovative alternative to other methods in welding manufacturing.

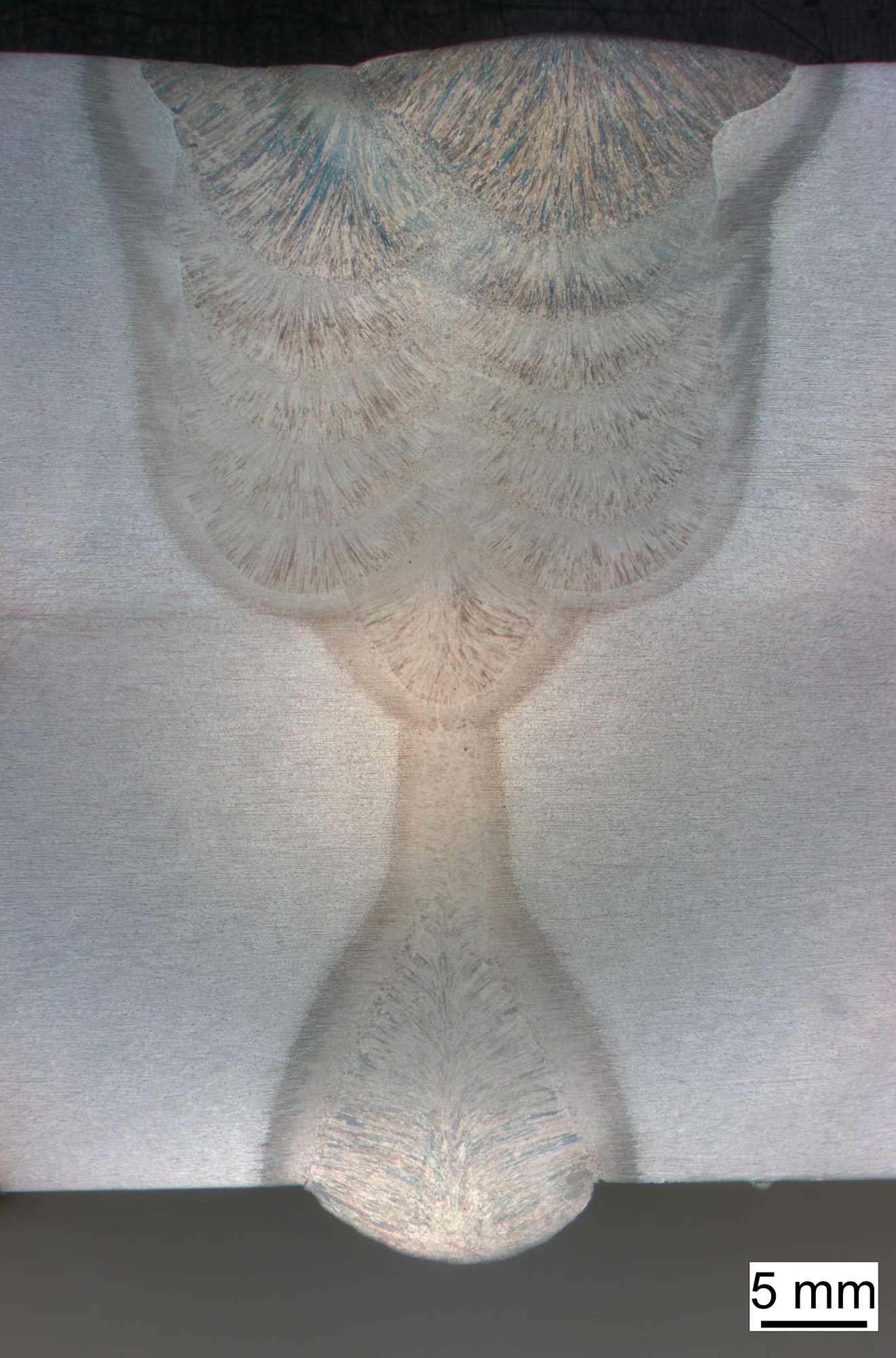

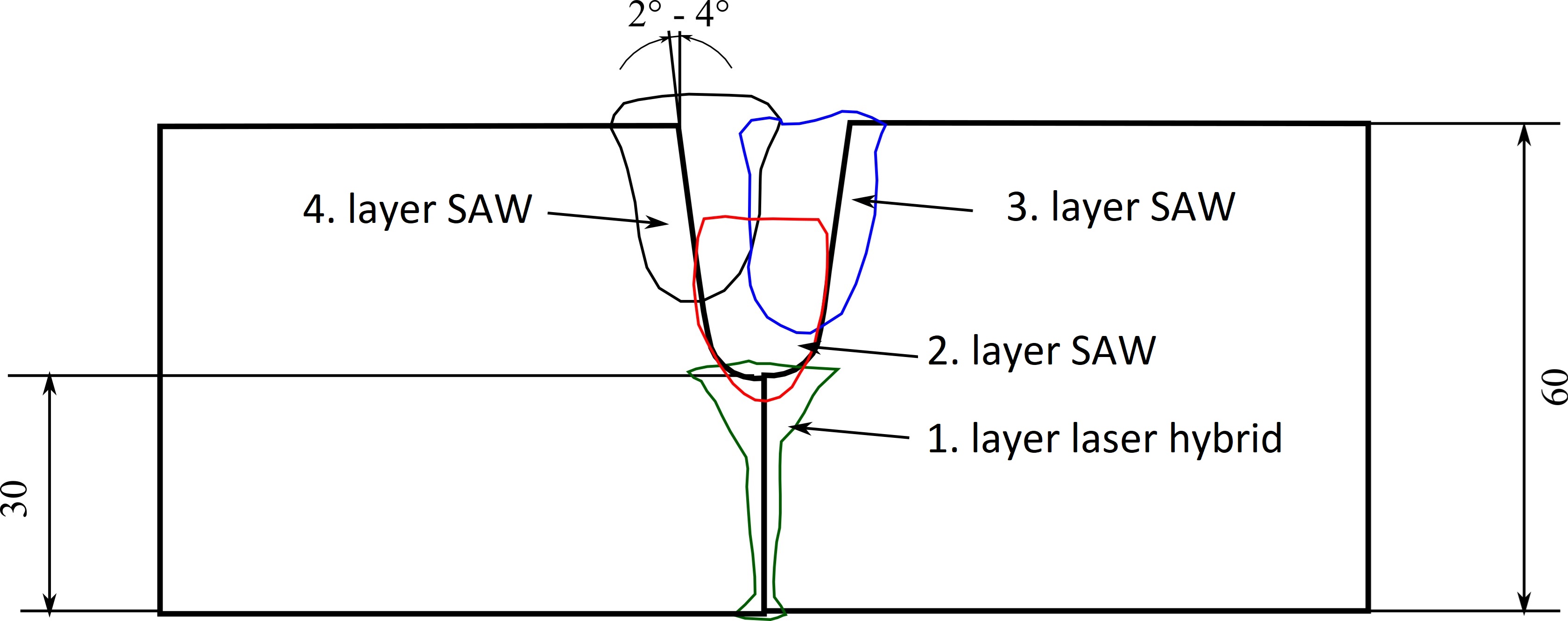

Researchers at Fraunhofer IPK are developing a new approach in which the efficient high-power laser hybrid process can be used in combination with narrow-gap submerged-arc welding to join thick-walled structures.

Combining the two welding processes will reduce manufacturing time and increase profitability while improving quality and competitiveness for many SMEs. It also significantly increases productivity in the manufacture of towers for wind turbines.

It has many economic advantages:

With this process variant, high plate thicknesses can be welded with a lower number of layers and lower heat input. This also reduces the cost of finishing, e.g. for stress relief annealing due to higher thermal load of the workpieces to be welded and the resulting residual stresses in the component.

The one-sided accessibility ensures that expensive handling techniques are not required. In addition, thick-walled components can be conditionally turned, which is a significant advantage to welding in position/opposite position.

Result:

Thanks to the expansion of production technologies and the use of new construction materials, efficient manufacturing is now possible. this was not technically or economically feasible with previous conventional welding processes.

The solution is interesting for these industries: