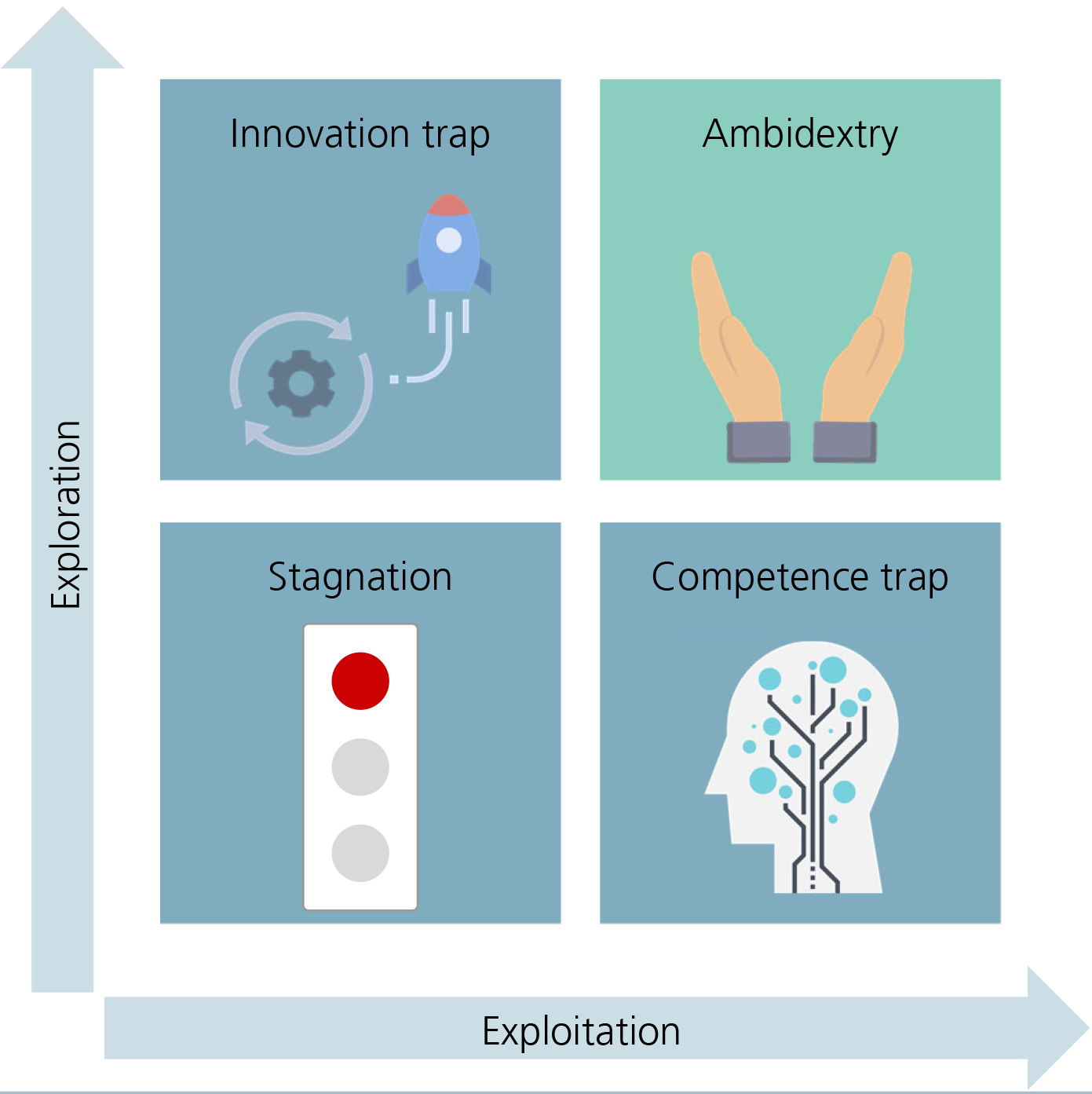

The holistic ambidextrous (Latin for "two-handed") approach, which refers to connecting and networking all areas along the value chain, is intended to close gaps for future production systems. To this end, a high level of stability in production must be ensured "on the one hand" and a rapid response to global market turbulence must be guaranteed "on the other hand".

AmbiProd – Ambidextrous Holistic Production Systems

Manufacturing companies are increasingly facing a wide range of strategic challenges in order to be efficient and at the same time agile in their actions and thus also capable of change. Currently available production systems often only include principles, methods and digital tools to increase resource efficiency. Due to the rigid structures, fast reactions to fluctuations in demand and supply chain problems are hardly possible. This is to be changed by combining efficiency- and agility-oriented principles and with the help of Industrie 4.0 applications, such as highly automated and self-organized processes. In order to be able to implement this organizational change in companies, the development of an ambidextrous management approach as well as a learning-coaching strategy for further education are planned as a supplement.

Vision

This vision was jointly developed and agreed upon by all project participants at the kick-off. In the course of the project, it is intended to serve as a guide, but also be alive and adapted if parts of the content no longer match the shared vision.

Our research will enable manufacturing companies to achieve an appropriate balance between the known and the new. They will thus be capable of taking advantage of best practices while at the same time seizing opportunities from innovations. In this way, companies will ensure rapid responsiveness in a dynamic environment and efficient alignment of day-to-day operations. The "operating system" to be developed for companies as a solution approach is intuitive and scalable. Societal challenges as well as the needs of people and the environment can only be mastered with innovative and at the same time economically successful companies. With our research work, we will make a practical contribution to this.

Operating System

The core of the ambidextrous holistic production system (GPS) consists primarily of a software model that defines the cooperation between the stable, efficiency-oriented GPS and the dynamic GPS for fast reactions. For this purpose, the specific conflicting goals and requirements for the solution system are first analyzed in companies, for example in the solar, aviation and automotive industries. This results in a target system configurator for aligning the corporate strategy, which allows the target picture to be adapted according to the changes in the corporate environment. Furthermore, an approach for organizational learning in the area of competence development is to be designed. For the realization of the ambidextrous GPS, a digital assistance system and a solution for automated software generation will be developed. The application partners will implement and validate the GPS in selected pilot environments. A virtual development platform will be established for interdisciplinary exchange with other projects and partners.

Social added value

For SMEs in the supplier industry, the targeted results offer great potential for securing corporate growth with the help of the methods and digital tools. At the same time, the ambidextrous GPS enables larger companies to strengthen their ability to change, for example in the form of faster responses to customer requirements. The virtual development platform creates a networking opportunity with other projects and partners. In addition, the transfer of results takes place via new consulting offers in manufacturing companies and management networks as well as via teaching and further education offers at universities.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology