TechEner - Technologies for Energy Savings in Production

Project description TechEner

Rising energy costs present manufacturing companies with major challenges. Many small and medium-sized companies, as well as large enterprises, need to develop solutions and concepts for saving energy in existing production processes without having to make significant investments.

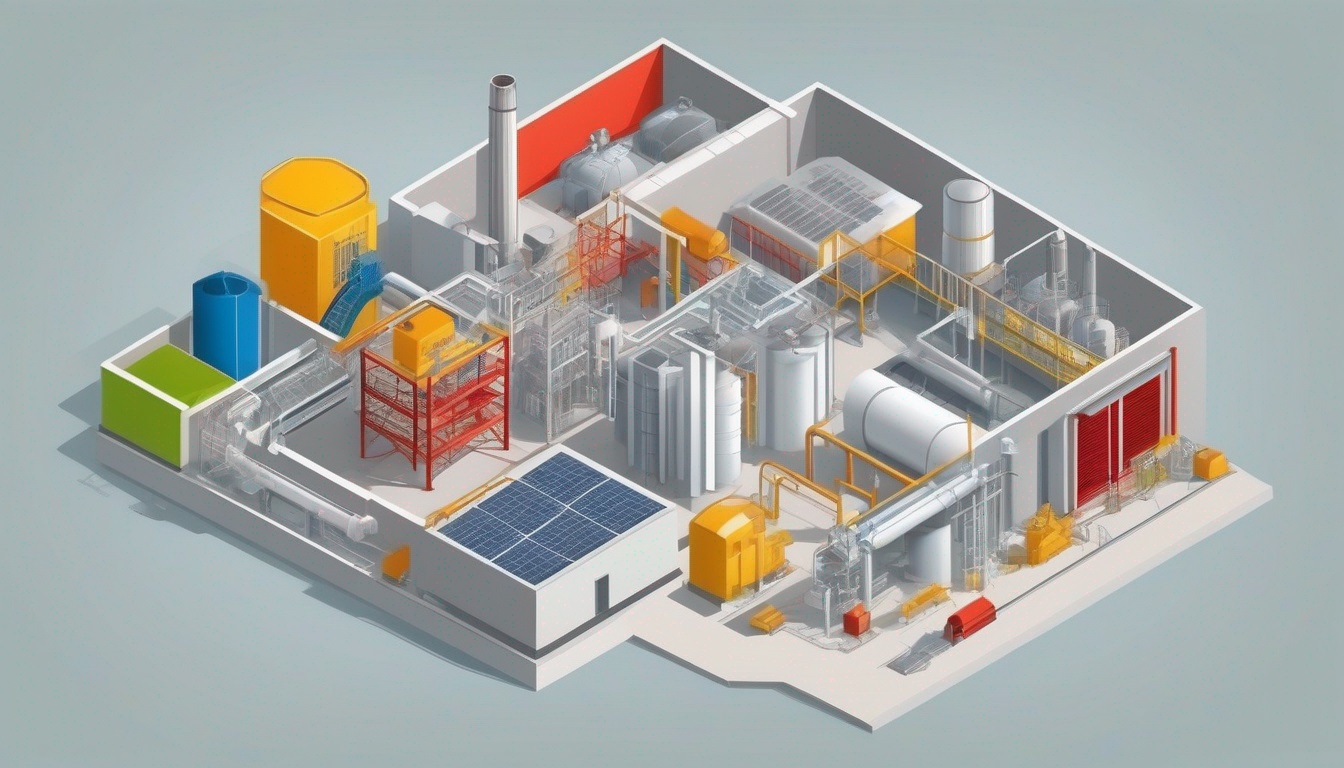

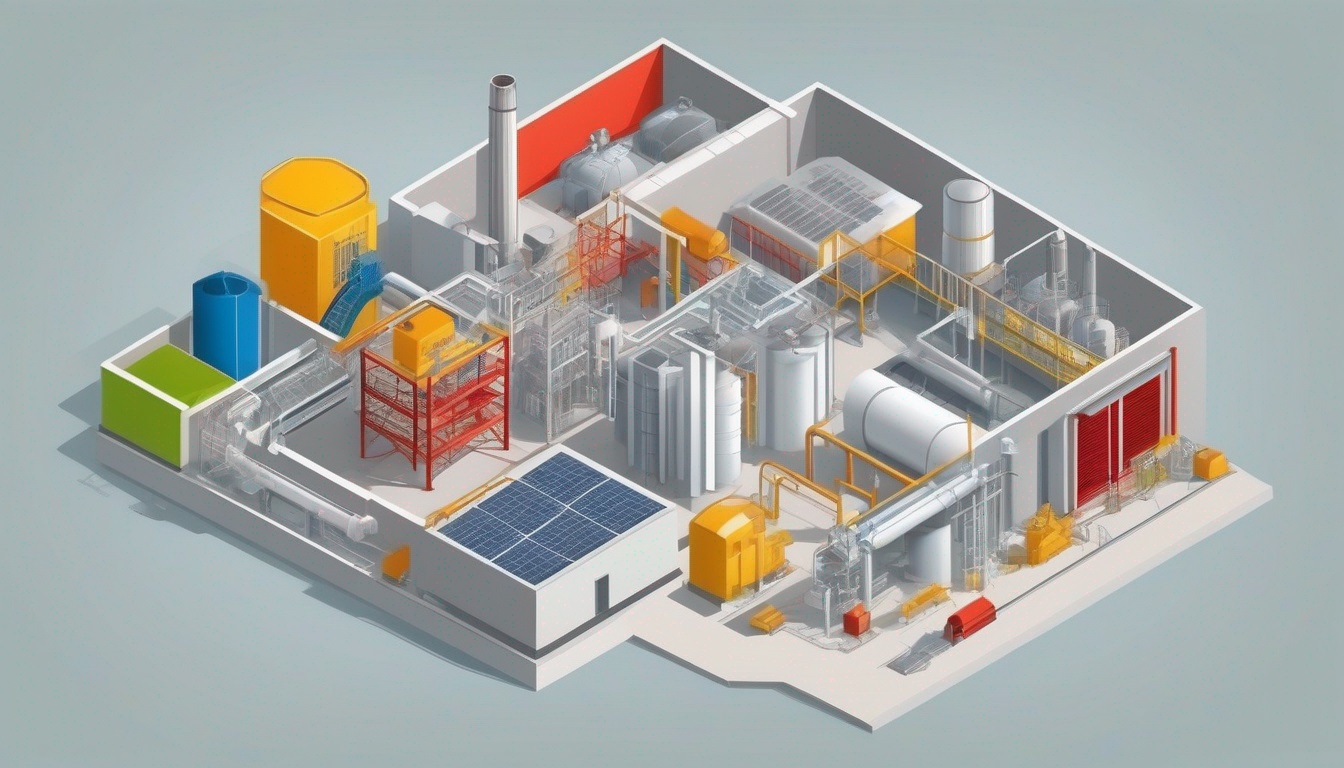

In the TechEner project, technologies and tools for targeted, high-resolution, cross-manufacturer and cross-machine energy monitoring are being researched, developed and made available to industry. The energy flows occurring at the process chain, machine, machine component and process level are to be analyzed with these methods and systems, using the example of a manufacturing process chain from the tool and mold making field that has been implemented in an application laboratory. Energy consumption can be balanced using specific production examples that can be achieved with the machines and systems in the process chain. Here, the technologies of grinding, drilling, milling, EDM, laser ablation and injection molding are addressed and the collected energy data is used for energy-specific process optimization. Based on the current state of the art, advanced technologies for data management and data analysis are being developed.

The technologies for energy consumption recording and analysis are then used to categorize process chains, machine tools and their components to identify and cluster major energy consumers. The results are then used as a basis for methodical process optimization with a focus on reducing energy consumption for the various technologies. In addition to technologies and specific systems for recording energy flows, methods for data analysis and evaluation as well as technologies and methods for the targeted optimization of energy consumption in existing industrial production chains will be developed and become available at the end of the project.

In addition to tool and mold making, the technologies addressed in the process chain are also found in mechanical engineering, precision engineering, medical technology as well as the automotive and aerospace industries.

Funding provider: ERDF funds of the Berlin Senate

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology