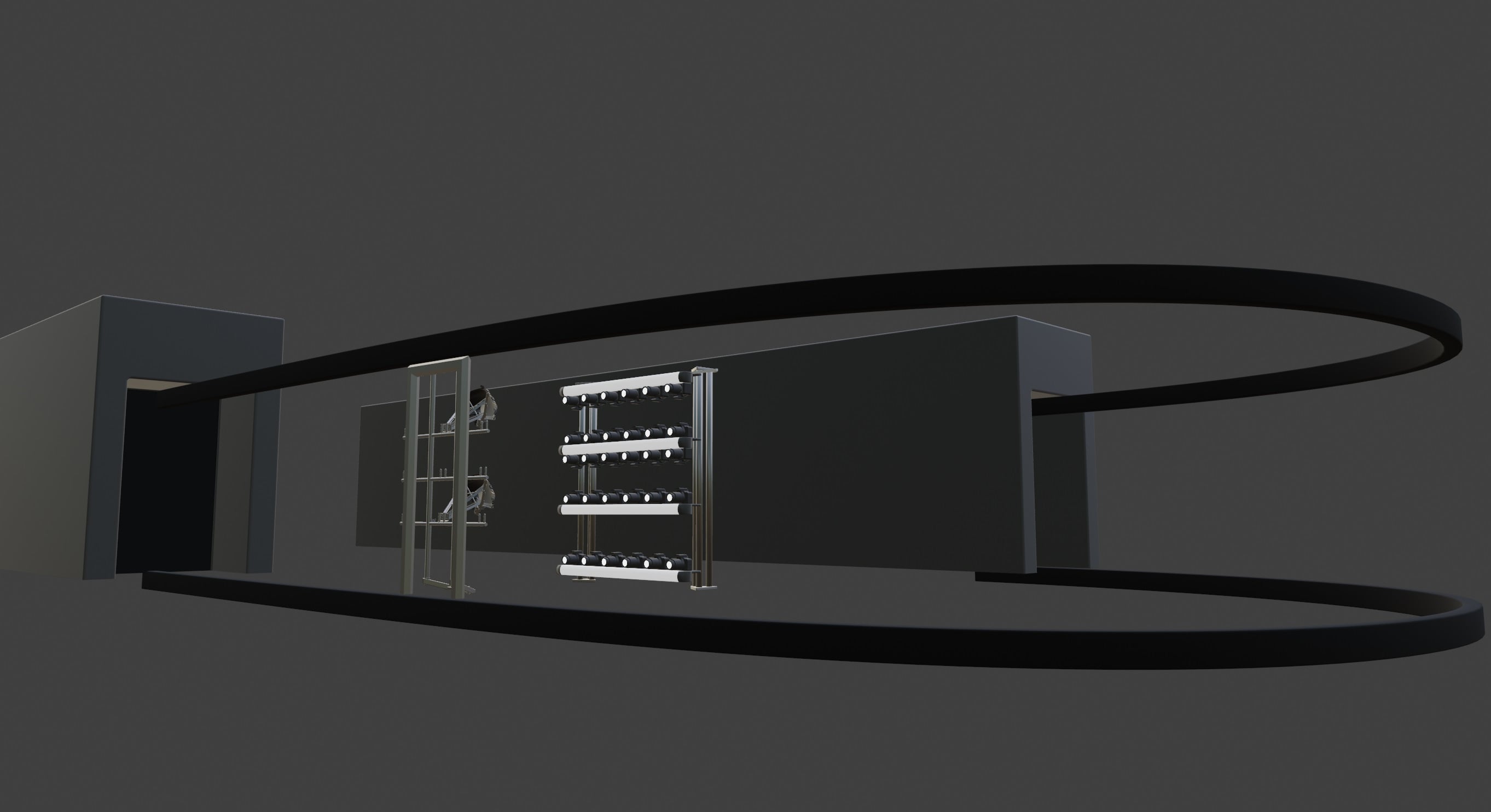

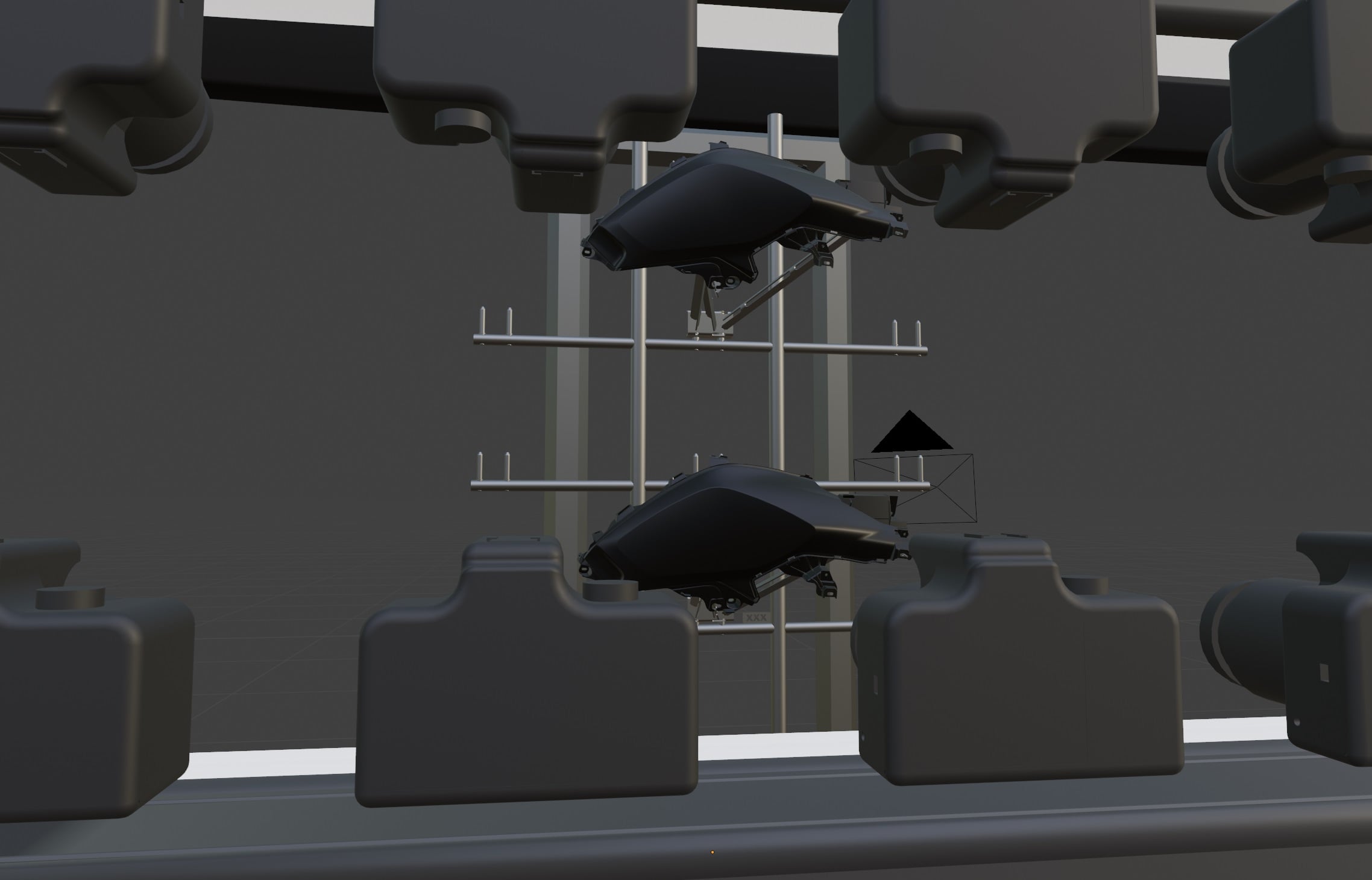

A production line features many objects which can appear in different shapes, materials and surfaces. The solution to be researched should be able to inspect all these objects and subsequently make a sorting decision based on predefined quality standards.

Particular attention is paid to the inspection of highly reflective, very dark and/or matt components. Automated quality control of such industrial products (e.g. painted car body parts) in the process takt and the requirement to perform a 100 percent inline inspection present major challenges for existing solutions.

Fraunhofer IPK focuses its research on the areas of defect detection and pose estimation using machine learning, as well as defect localization in multi-camera systems, researching assistance systems for process optimization and integrating expert knowledge acquired in this research into the learning systems.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology