AIQuAM3D – Embedded Artificial Intelligence for Quality Assurance in Additive Manufacturing and for Advanced 3D Material Characterization

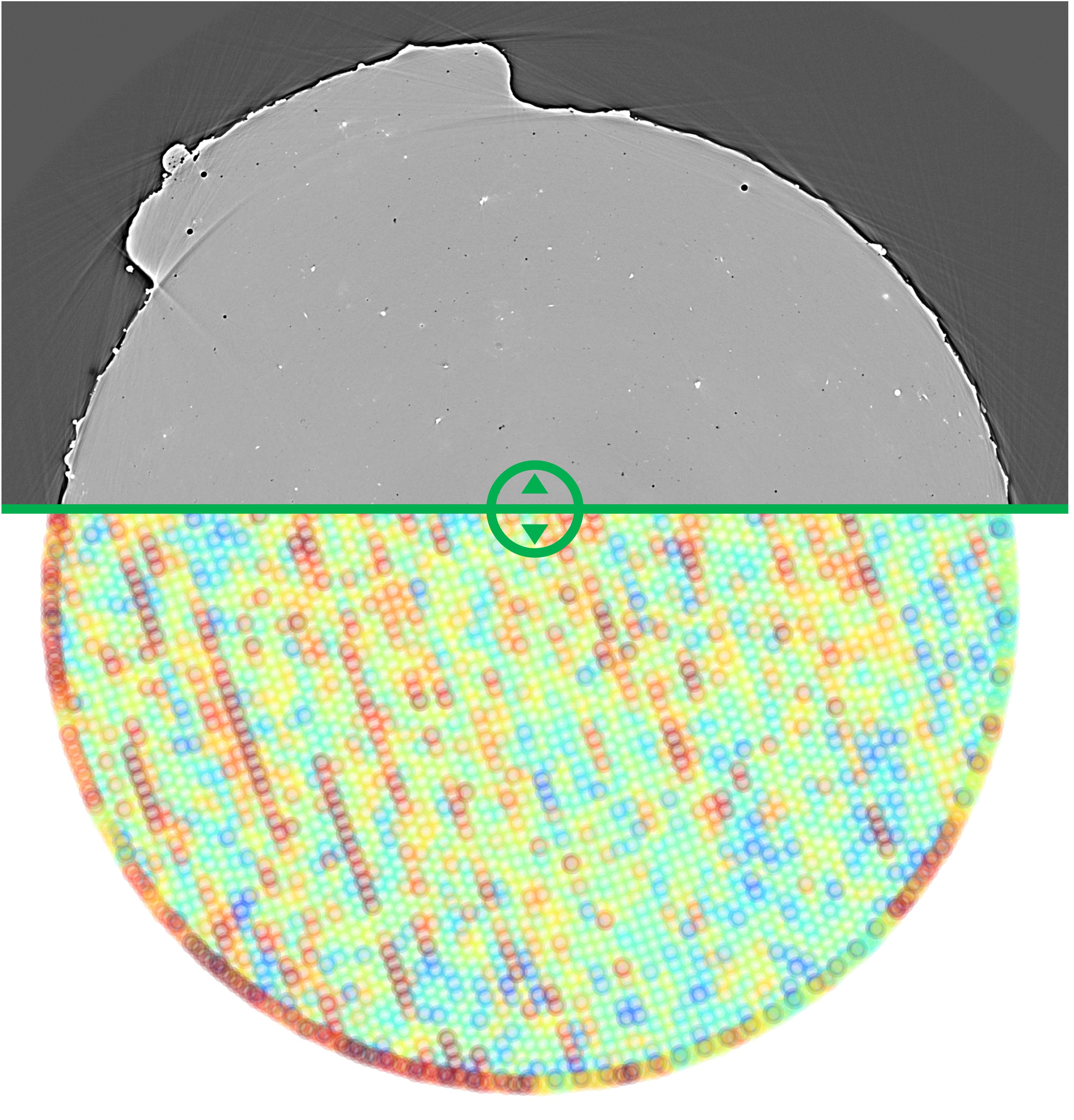

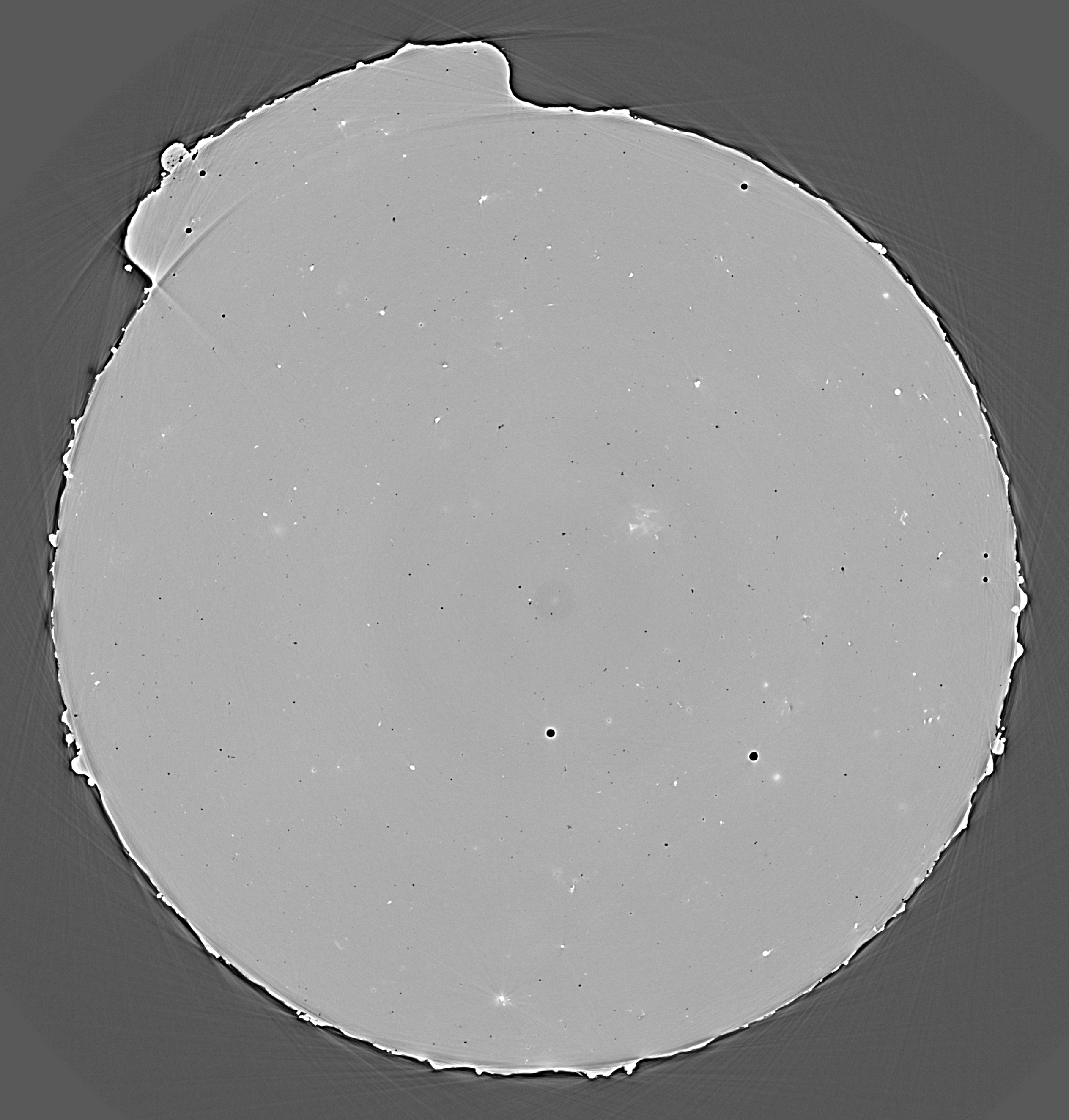

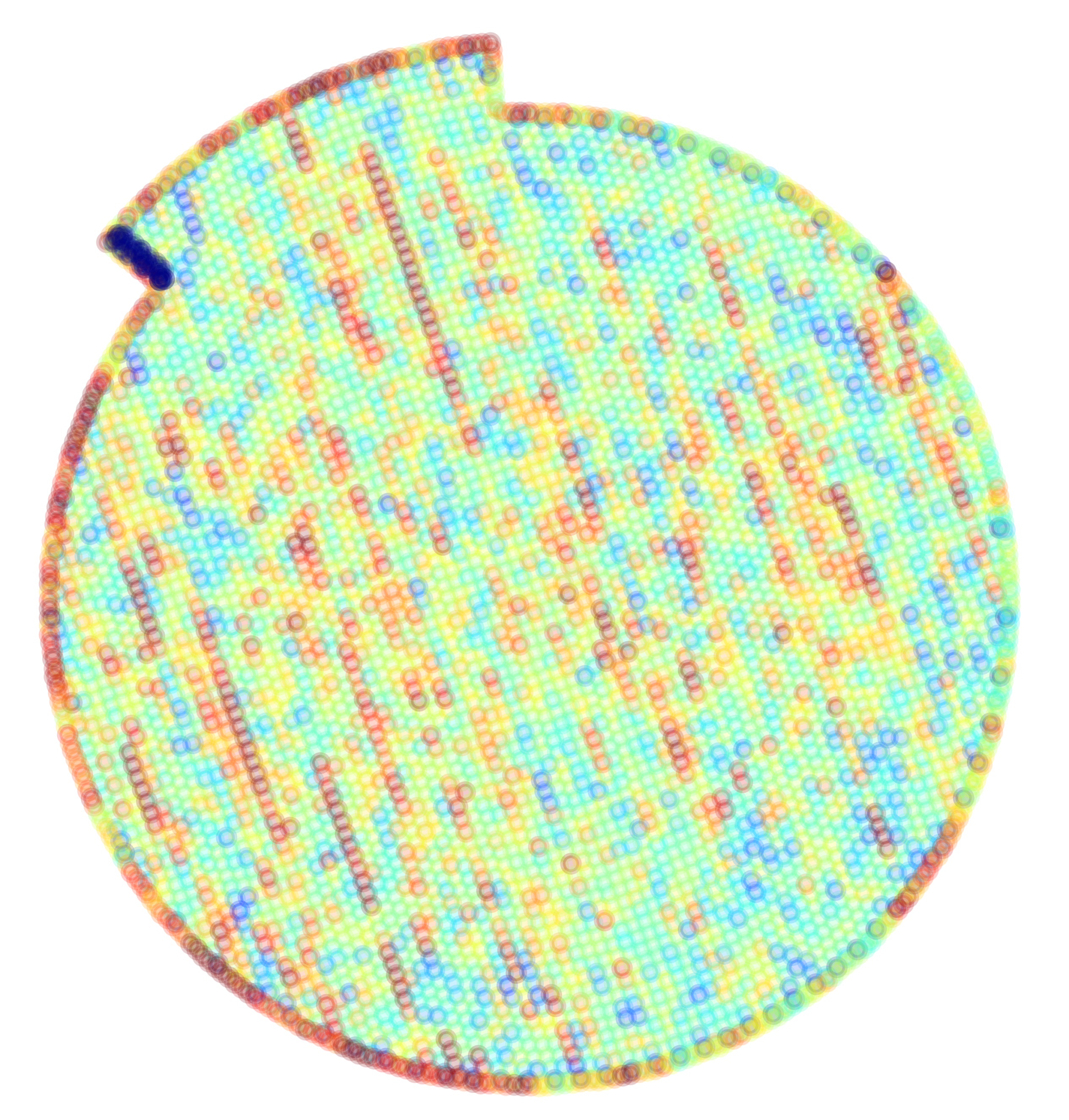

Additive manufacturing (AM) is increasingly gaining industrial attention due the level of flexibility and adaptability it offers to product design and production processes. However, especially for safety critical applications, lack of process qualification still hinders a massive industrial adoption of AM. Commercial systems typically operate without closed-loop process control, making nondestructive testing an almost mandatory step in the approval of AM parts. In the case of metallic materials, synchrotron-based micro-computed tomography (SR-µCT) is a particularly suitable technique due to the high energy level of the X-ray radiation achieved (i.e. higher penetration depths, shorter measurement times). Still, synchrotron facilities and their capabilities are still far from industrial reality.

The AIQuAM3D project is a binational applied research and development project between Germany and France. It has a collaborative and industry-oriented approach and aims to establish artificial intelligence (AI) as a tool to support the industrialization of AM technology and to help achieve the democratization and widespread use of SR-µCT by industry. The overall goal of AIQuAM3D is to further develop AI models and tools for quality assurance with respect to their direct applicability in an industrial environment.

The innovations proposed by AIQuAM3D can be divided in two related domain areas: quality assurance in AM and advanced 3D material characterization. A model for detecting bulk defects (such as porosity, lack of fusion, and cracks) during the AM process will be developed based on in-situ monitoring data from multiple embedded sensors. The ground truth for the training of this model will be SR-µCT data, whose acquisition and processing will be supported by in-house developed AI tools. The application of AI methods is a common technological strategy chosen to solve open data-intensive issues of industrial relevance in the domain areas of AIQuAM3D.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology