Intelligent decision support systems can help prevent sudden major disruptions caused by absences.

more info

Intelligent decision support systems can help prevent sudden major disruptions caused by absences.

more info

Without a plan and strategy, sustainability can cause considerable costs. A new in-house training program teaches concepts, methods and technical solutions alike.

more info

Steel as a sustainable lightweight material? What appears contradictory at first could revolutionize the design of battery housings for electric vehi-cles, making e-mobility even more eco-friendly.

more info

The ReTraNetz-BB real-world laboratory supports the local vehicle and supplier industry’s turnaround. Process chains are tested here and technologies are transferred into real-life scenarios.

more info

In volatile times, one thing matters more than ever: Both production and products must be safe and reliable. At the IWF of TU Berlin, industrial safety is addressed from many angles.

more info

Ready for digitalization in production? With the help of an AI-based learning platform, SMEs can prepare their employees for their individual roles in a digitally integrated production.

more info

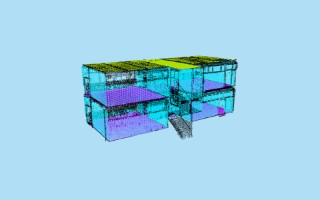

Existing buildings are responsible for one third of all carbon emissions in Germany. In order to renovate them efficiently on the basis of 3D models, the Scangineering process is being adapted.

more info

Many machining companies face the same dilemma. They collect process data during production, yet expertise for contextualizing and evaluating it is often missing. Triggered sensors can help.

more info

Generative AI is revolutionizing the way we interact with knowledge. How can companies take advantage of this development to manage their domain knowledge?

more info

Keeping emissions in focus: Benchmarking greenhouse gas emissions enables quick comparisons of sustainable business developments.

more info

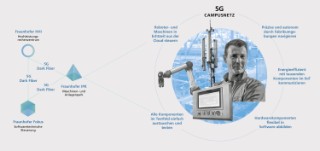

Starting at the end of 2020, companies will be able to test factory processes in a 5G infrastructure in the PTZ test field.

more info

Artificial intelligence requires large quantities of data? Not necessarily, say scientists at Fraunhofer IPK. They use visual quality control for industrial goods to show how it can work.

more info

Within the framework of the research project BioFusion 4.0, data-driven solutions for a more sustainable and resource-efficient production are being developed at Fraunhofer IPK – inspired by principles from nature.

more info

The partners in our expert discussion are researching how the surfaces of implants can be improved to prevent clinical complications.

more info

Current headlines on the automotive industry in Germany are mostly a cause for headaches. Meanwhile, experts at Fraunhofer IPK are paving the way out of the crisis.

more info

In today’s production systems, even small changes are often time-consuming, costly and susceptible to errors. The story changes when development, planning, commissioning and production are integrated and understood together.

more info

Non-invasive real-time quality control in additive manufacturing processes has long been wishful thinking. Researchers can now collect data and inspect parts during processing without destroying them.

more info

A passenger flight in 2050: low-emission, quiet, safe, affordable? The aviation industry faces enormous challenges on the journey to a new generation of propulsion systems.

more info

Circular Economy: Effective take-back management and recycling enable companies to not only save material costs but also reduce their ecological footprint.

more info

Products and services have had a complicated love story. Can decentralized data spaces give their relationship the room it needs to grow?

more info