The first draft rarely is the final one in product development. With the help of artificial intelligence, this labor-intensive but essential stage can be accelerated.

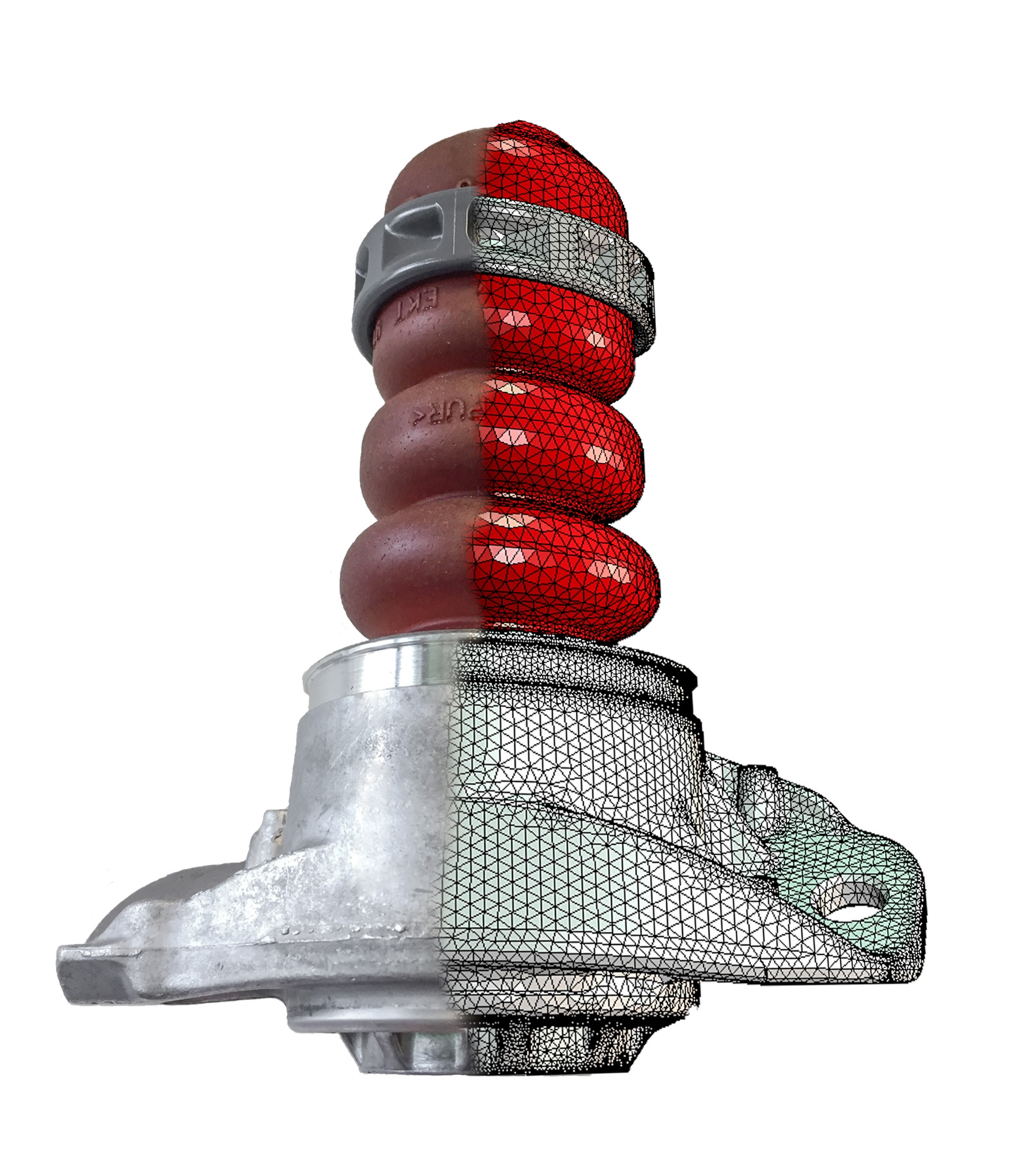

Whether it is a gasoline car or an electric vehicle, an SUV or a compact car, a sports car or a family vehicle – comfort is a crucial factor in the purchase of a car. The damping system, consisting of shock absorbers and additional springs, is essential for this. To ideally adapt the latter to the specific needs of certain cars and achieve the best possible comfort, iterative tuning processes and expert knowledge have always been a requirement. Commissioned by BASF Polyurethanes GmbH, a manufacturer of additional springs in the automotive industry, researchers at Fraunhofer IPK have now developed a process that aims to simplify the design of such additional springs using artificial intelligence. The goal is for AI to derive a suitable component directly from the customer’s requirements.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology