Driving Research Forward

According to the Federal Ministry for Economic Affairs and Climate Action, the domestic automotive industry is »by far the most important industrial sector in Germany«. This is confirmed by data from Statista, according to which the industry has a turnover of around 613 billion euros annually, employing over 770,000 people nation-wide. However, various global, European and national developments are increasingly putting this proverbial engine of the German economy under pressure.

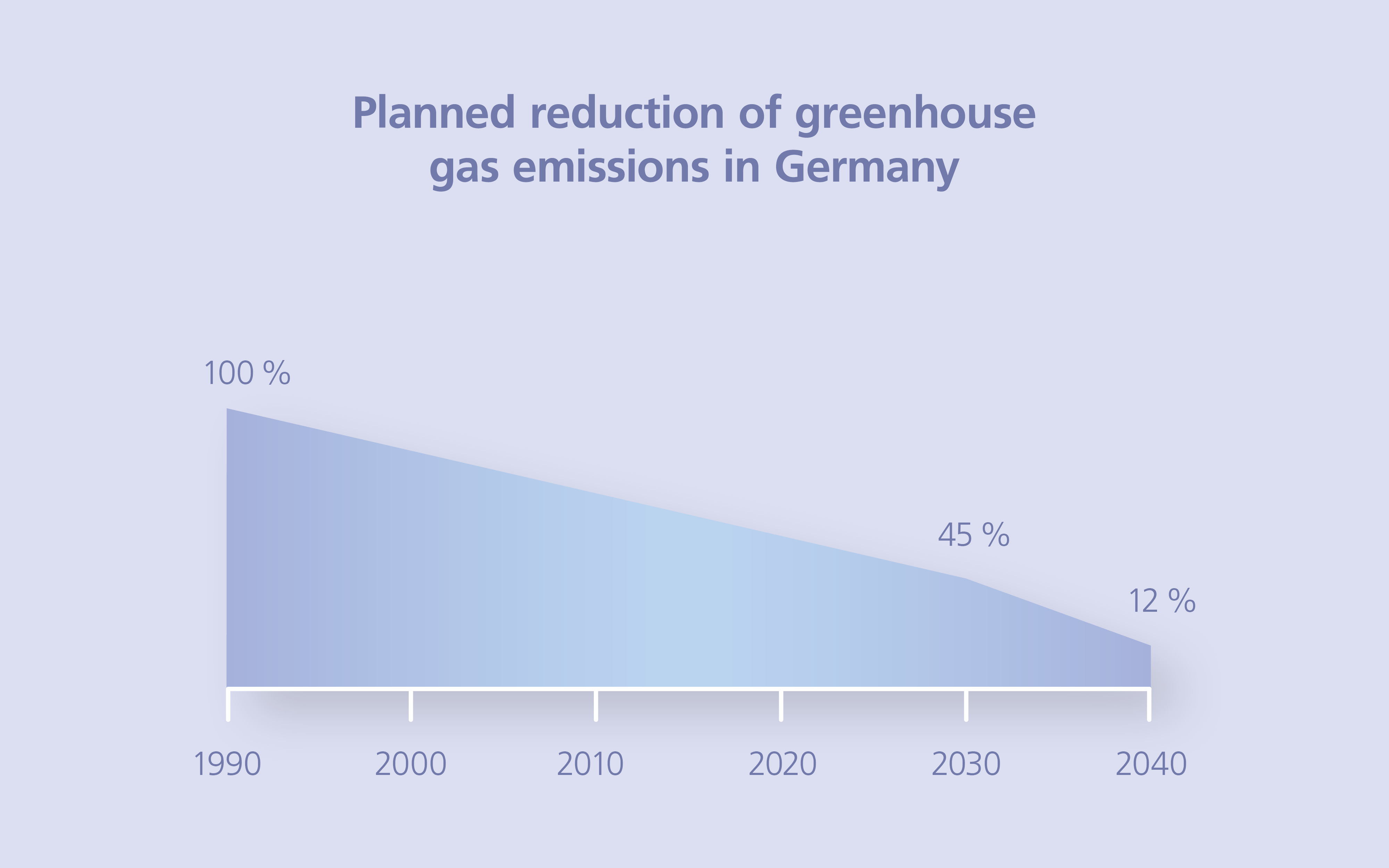

Take tighter regulatory conditions, for example: The European Green Deal aims to make Europe the first climate-neutral continent by 2050. On the way there, net greenhouse gas emissions must be reduced by more than half by 2030 compared to 1990. The European Climate Law creates a legally binding framework for EU climate neutrality by 2050, while the German Climate Protection Act sets binding targets for reducing greenhouse gas emissions in Germany. By 2040, 88 percent of emissions are supposed to be avoided compared to 1990.

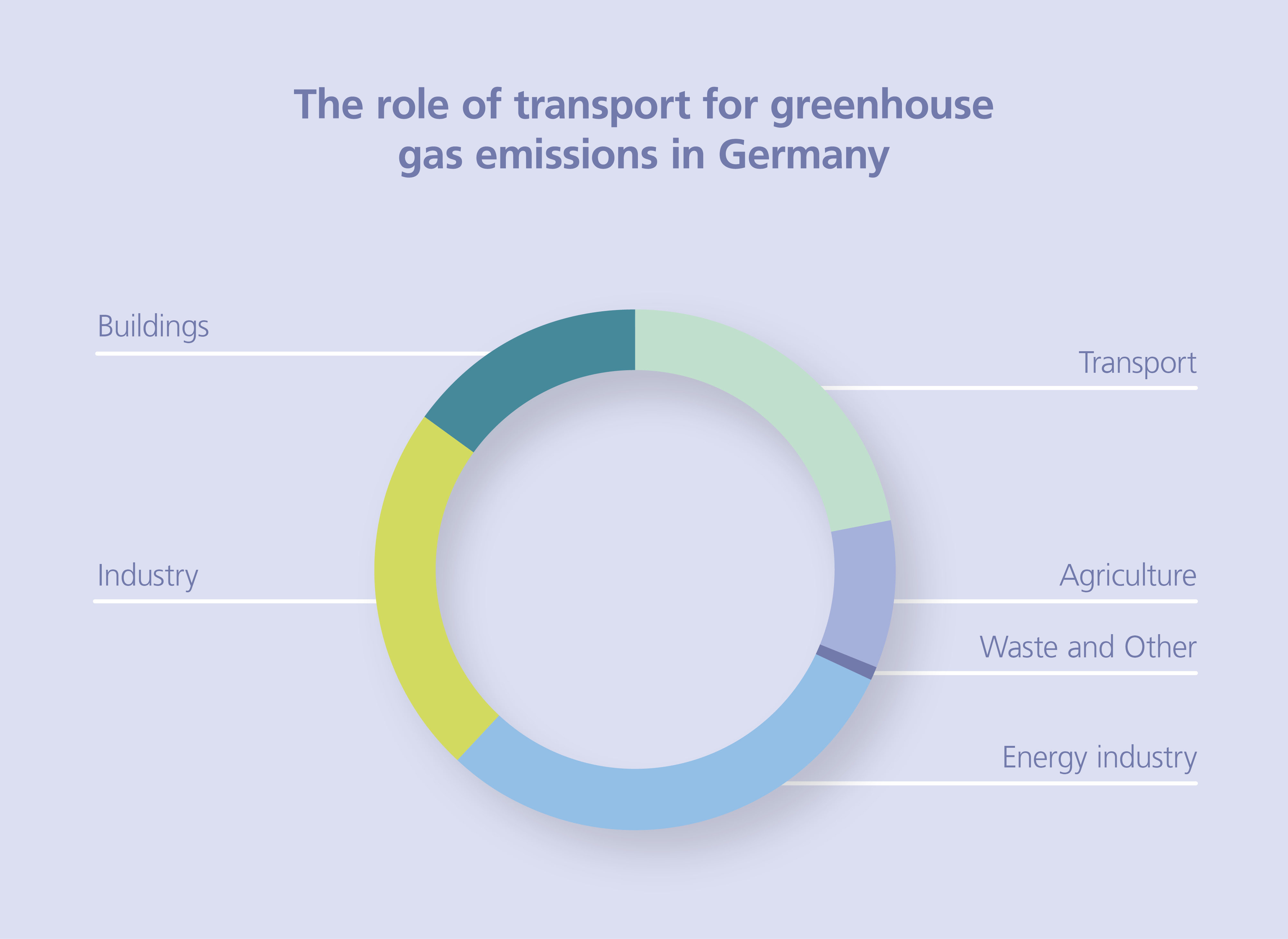

In 2023, the transport sector was responsible for over a fifth of the greenhouse gases (GHG) emitted in Germany, making it an important lever for reducing emissions. Politics, legislation and society have therefore taken the initiative to dictate conditions for the transformation of the automotive industry.

One thing is clear: The classic gasoline engine will soon have served its purpose. Which drive technology will prevail in its place, however, is less certain. Battery-powered electric vehicles tend to attract the most media attention and, given the resources currently available, are the most sensible technology right now. Science and research, however, are already discussing the further development and integration of hydrogen technologies. Which scenarios and perspectives are on the table, and what do they mean for the automotive and supplier industries in Germany?

The market reacts

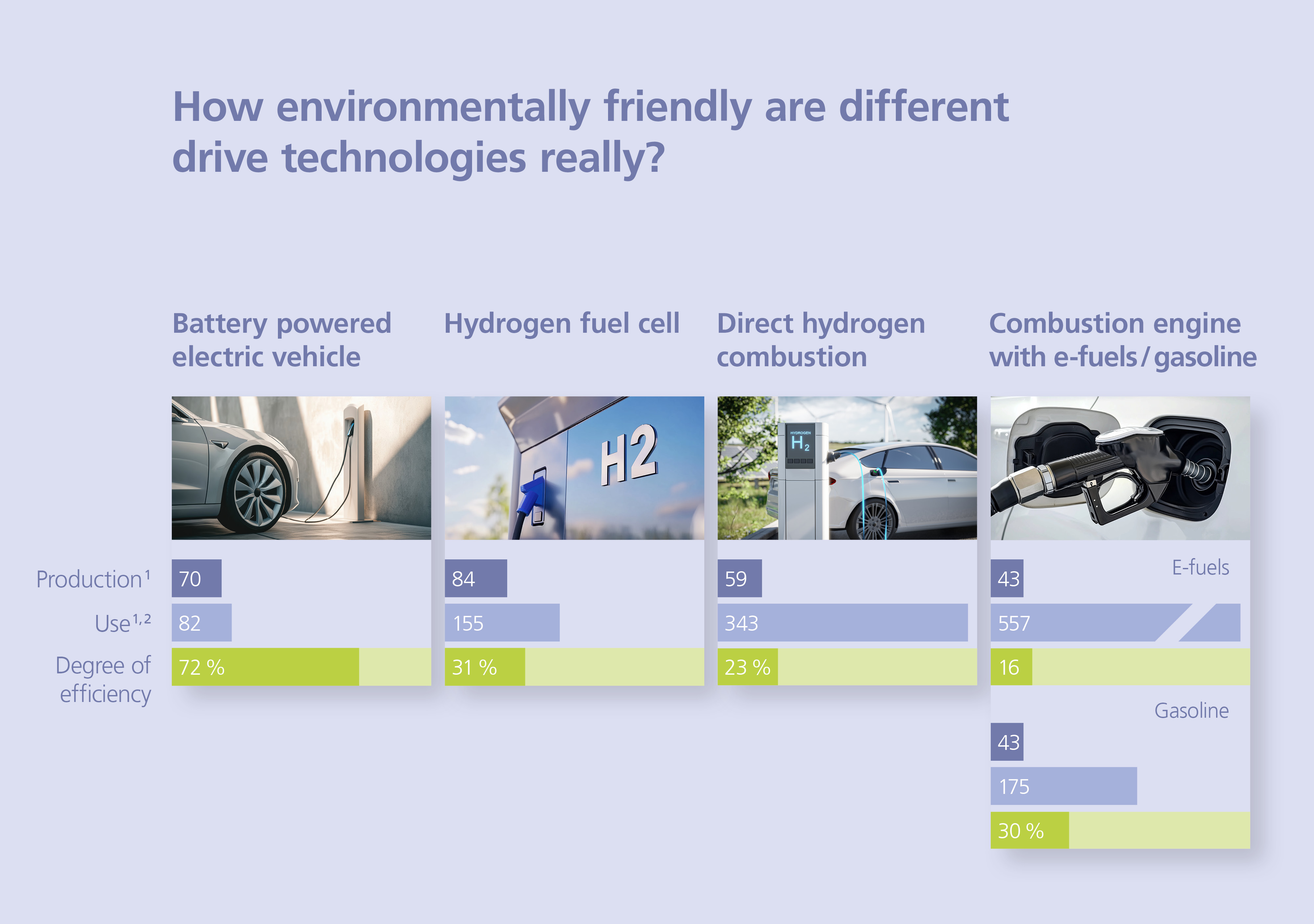

German companies such as BMW and Volkswagen are pursuing a range of different strategies. BMW, in collaboration with Toyota, plans to launch the first hydrogen car into mass production by 2028, while Volkswagen is aiming for 70 percent electric cars by 2030. These trends show that manufacturers are clearly focusing on developing sustainable alternative concepts in order to meet regulatory and societal demands. All of them are grappling with the question of how to scientifically substantiate the various approaches. In other words: Which technologies should they focus on? The various drive technologies have different degrees of efficiency, which is crucial for reducing carbon emissions.

Among the alternative drive technologies, battery electric vehicles (BEV) have the highest overall efficiency. Their production, however, causes significant carbon emissions, mainly due to the use of materials such as cobalt or rare earths. Producing a conventional combustion-powered vehicle currently emits 39 percent less CO2 than would be the case for a BEV.

However, if we consider the entire life cycle of a vehicle, operation plays a greater role than production across all drive types. For e-fuels, hydrogen and BEV, emissions are determined by the electricity mix. Currently, about 55 percent of Germany’s electricity comes from renewable sources. The remaining 45 percent come from predominantly non-renewable sources which results in significant carbon emissions due to their low efficiency, especially in the case of hydrogen-powered vehicles. Even with completely climate-neutral electricity generation, a car with a hydrogen fuel cell drive would still have to travel a total of 41,000 kilometers to offset the carbon emissions created during its production, compared to a gasoline-powered car – that is equivalent to driving around the entire planet. Direct hydrogen combustion can offer a good alternative here, even if its efficiency is slightly lower.

Hydrogen in all its shapes and forms

| CO2 emissions per MJ H21 | |||

| Color | Production | Current energy system2 | Future energy system3 |

Grey hydrogen |

Steam reforming using steam from fossil fuels such as natural gas, coal and oil | 134 g | 54g |

Blue hydrogen |

Like grey hydrogen, but the CO2 produced is stored underground (CCS technology) | 103 g | 16 g |

Turquoise hydrogen |

From methane using high-temperature processing (pyrolysis) | 108 g | 17 g |

| Green hydrogen | By water electrolysis | 13 g | 0 g |

1 Emissions are given in g CO2 e per MJ H2 or »grams of CO2 equivalent per megajoule of hydrogen«

2 with the electricity mix of the current general supply

3 with electricity from renewable sources

Source: Umweltbundesamt

The hydrogen dilemma

Hydrogen offers several advantages over conventional fuels such as gasoline or diesel, but it also presents challenges:

- Relative to its mass, hydrogen has three times the energy content of gasoline. However, due to its lower density, its energy content per volume is only one-third. Larger tanks are therefore required for the same range when hydrogen is stored in gas tanks.

- Hydrogen has a very wide ignition range, which allows for good partial load efficiency, but also makes it dangerous to handle.

- The ignition energy is significantly lower than for other gasoline fuels. This makes hydrogen very sensitive to unwanted pre-ignition.

- The lack of lubrication provided by the fuel is another disadvantage compared to hydrocarbon-based fuels.

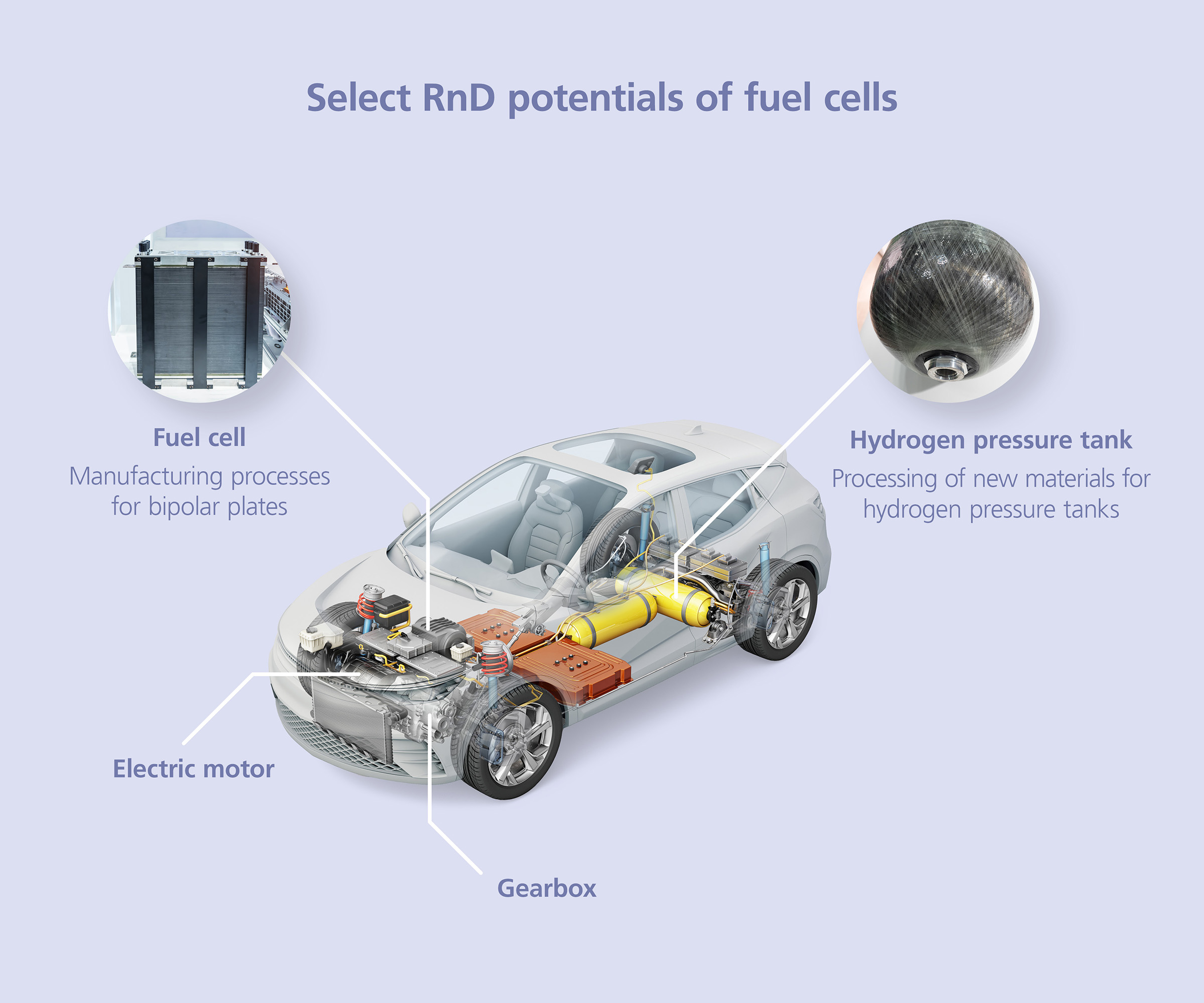

These challenges require scientific solutions: Researchers in production and materials science have identified several promising areas to improve fuel cell electric vehicles (FCEV) and are working on implementing them.

Producing hydrogen tanks from carbon fiber-reinforced plastics (CFRP) offers great potential, as these provide high strength combined with low weight. CFRP tanks enable a weight reduction of up to 72 percent compared to metallic tanks. However, they cause high carbon emissions during production – around 2,210 kg CO2e for 350 bar tanks and 2,670 kg CO2e for 700 bar tanks. Advances in fuel tank production are therefore crucial to making hydrogen fuel cells competitive as a low-emission mobility solution.

The fuel cell itself consists of up to 200 individual components, centered around the bipolar plates through which the hydrogen is channeled. Instead of milling them individually, these plates are increasingly being manufactured in series through forming processes using metallic materials such as stainless steel, titanium or aluminum, which reduces their production costs and improves durability. Optimized channel structures within the bipolar plates can improve gas flow and increase the efficiency of the fuel cell. When chemical energy is directly converted into electrical energy without thermal losses, degrees of efficiency of up to 60 percent are possible. This makes the fuel cell an efficient and environmentally friendly drive solution.

Select RnD potentials of hydrogen drives

Why take a detour when you can go straight?

Direct hydrogen combustion is a promising transitional technology that can be more easily integrated into existing combustion engines. This makes it less disruptive than other alternative drive technologies, as existing engines can continue to be used with moderate adjustments.

Since the hydrogen flames burn right up to the cylinder walls, the ceramic coatings of the pistons are crucial to minimize thermal stress and wear. Because hydrogen mainly burns to water vapor, this type of combustion results in CO2-free exhaust gases and lower emissions of nitrogen oxides (NOx).

Fuel is injected by specially developed injectors, while the valve system must ensure optimal sealing and maximum efficiency through highly precise manufacturing of the valve seats. Additional measures such as a leaner mixture and cooled exhaust gas recirculation at high pressure are required to further reduce NOx emissions.

There is still a lot of research to be done in the area of direct hydrogen combustion – but overall, it represents a practical solution to ease the transition to zero-emission drives and make use of existing infrastructure. Today, research scientists at Fraunhofer IPK are exploring new technologies to meet tomorrow’s challenges of using hydrogen as an energy source. In doing so, they not only consider new components that are immediately necessary, but also the implications along the entire life cycle of a vehicle.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology