From wearable robotics to virtual reality, people and machines are collaborating in more and more ways. In the process, the real and digital worlds are merging.

more info

From wearable robotics to virtual reality, people and machines are collaborating in more and more ways. In the process, the real and digital worlds are merging.

more info

Virtual commissioning makes it significantly simpler to integrate new equipment into a manufacturing environment. The simulation becomes even clearer through the use of virtual reality technologies.

more info

A flexible robot system and an autonomous vehicle all in one: The Tend-O-Bot eliminates the need for rigid automation solutions in production. However, this can only be achieved with a change of perspective.

more info

»Workerbot 1« was the name of the first robot developed by the Berlinbased company pi4_robotics in 2010. Today, the 8th generation of Workerbots support industrial companies in handling, assembly and inspection, but the humanoid helpers are also used for building monitoring, concierge services, catering or the care sector. Founder and CEO Matthias Krinke explains in this interview with FUTUR that good technology needs emotions – especially when humans and machines work together.

more info

Human-machine interaction calls for empathy and inventiveness to satisfy the needs and requirements of users. Design methods can help, but they must not be used in a way that focuses too much on user experience at the expense of usability.

more info

Researchers at TU Berlin's IWF are developing a solution that combines the advantages of AI and humans for automated quality assurance and control in additive manufacturing.

more info

New technology for modularization in assembly helps manufacturers to make their processes future-proof. The goal is to integrate humans in the best possible way.

more info

Robots have become an indispensable part of our working world. Museum curator Marlies Wirth and automation expert Prof. Dr. Jörg Krüger discuss the ethical and cultural issues arising from this fact.

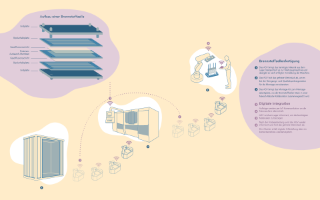

more info»In 500 meters, turn right.« When driving, we are happy to rely on digital assistance from navigation systems. Wouldn’t it be great, if we could get the same kind of simple instructions for complex production processes? Fraunhofer IPK is developing solutions for digital assistance systems that provide users with tailored, adaptable support.

more info

How can the production of fuel cells become economical? In the application laboratory »Digitally Integrated Production (dip)«, solutions for individual and small series production are to be developed.

more info