Innovate to Renovate

The odds have never been more favorable for energy refurbishments of existing buildings: Since February 2022, the application process for funds from the Federal Support for Efficient Buildings (BEG) has once again been opened. There is a reason why the new federal government implemented this so soon after taking office: The refurbishment of existing buildings is possibly the area with the greatest potential for CO2 savings, as almost a third of all German greenhouse gas emissions are attributable to this sector.

Easier said than done

Today, new virtual technologies such as Building Information Modeling (BIM) support architects and civil engineers from the outset. Buildings are planned and constructed virtually in the form of digital 3D models. During and after the construction phase, real data can be used to validate the building's condition and check it against the planning data. In 2017, dena (German Energy Agency), a think tank of the Federal Republic of Germany and the KfW banking group, already noted that thanks to BIM, »renovation costs could be cut almost in half« in a pilot project.

However, BIM modeling today faces a major challenge: It must be possible to represent existing buildings virtually in order to benefit from the advantages mentioned above. In Germany, the majority of these structures was built over 40 years ago and was thus designed and documented entirely on paper. Digital data on such buildings is, therefore, rare.

The transfer of analog data into virtual formats usually has to be carried out manually by skilled personnel. But the construction industry is also affected by the general shortage of skilled workers. The Federation of German Industries (BDI) therefore concludes in its guidance on the Climate Paths 2.0 study: »Capacity shortages among skilled craftsmen, architects [...] are standing in the way of the urgently needed wave of renovations.

«Meanwhile, measures are imperative in order to still be able to meet the European energy and climate targets in the construction sector: »The number of energy-related renovation of buildings must double,« according to BDI. Achieving such a quota while facing a shortage of skilled workers will only be possible if professionals are supported in modeling the building stock with the help of automated software technologies. Researchers at Fraunhofer IPK have therefore teamed up with the start-up pointreef to further develop their technology for automated processing and feedback of point clouds to CAD models into a marketable product for the construction sector.

From Scanineering to ARGOS

The collaborative project »ARGOS – Automated Feedback of Building Models from Optical Scan Data« is funded by Fraunhofer's internal funding program AHEAD and is based on a software prototype called Scangineering.

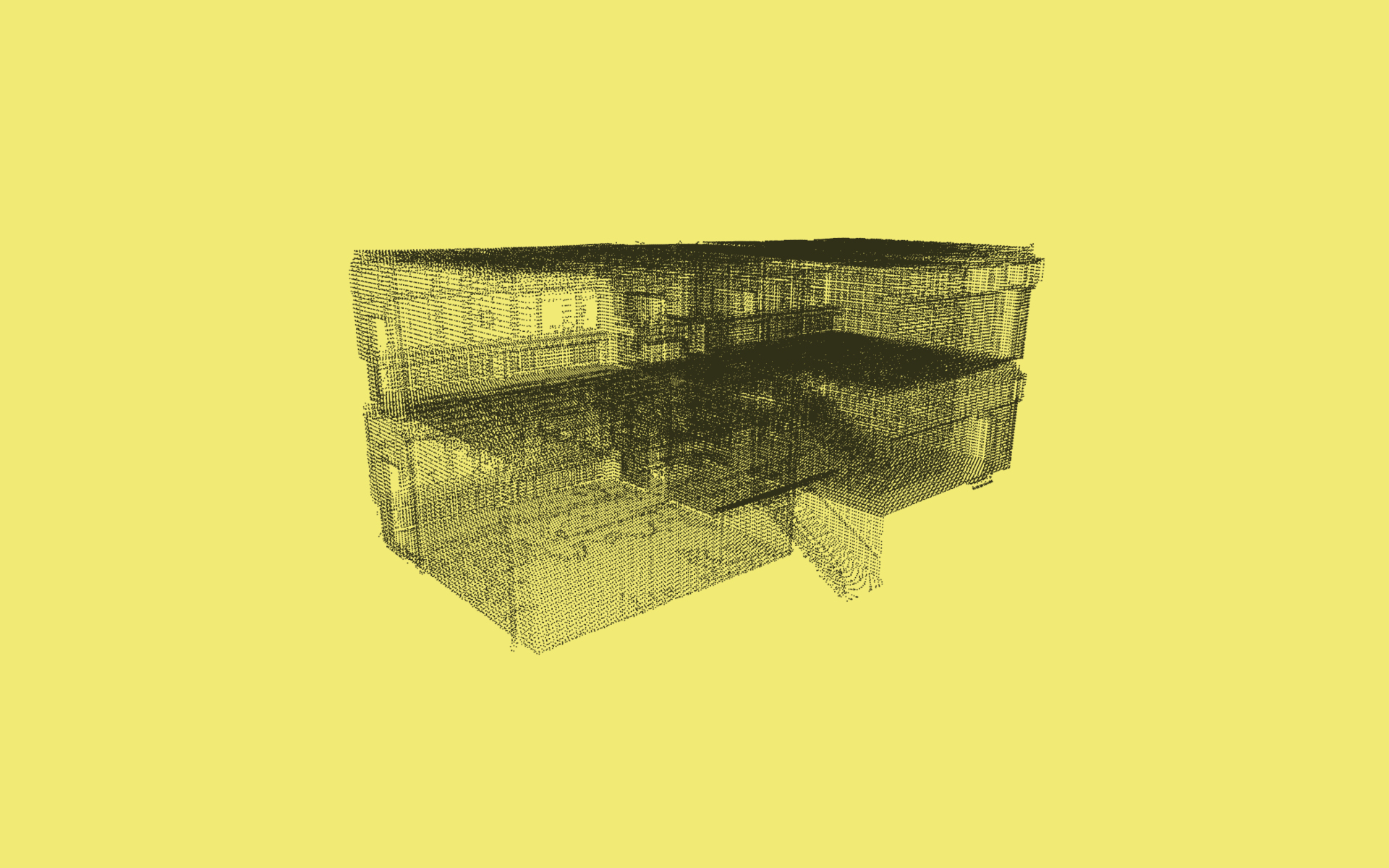

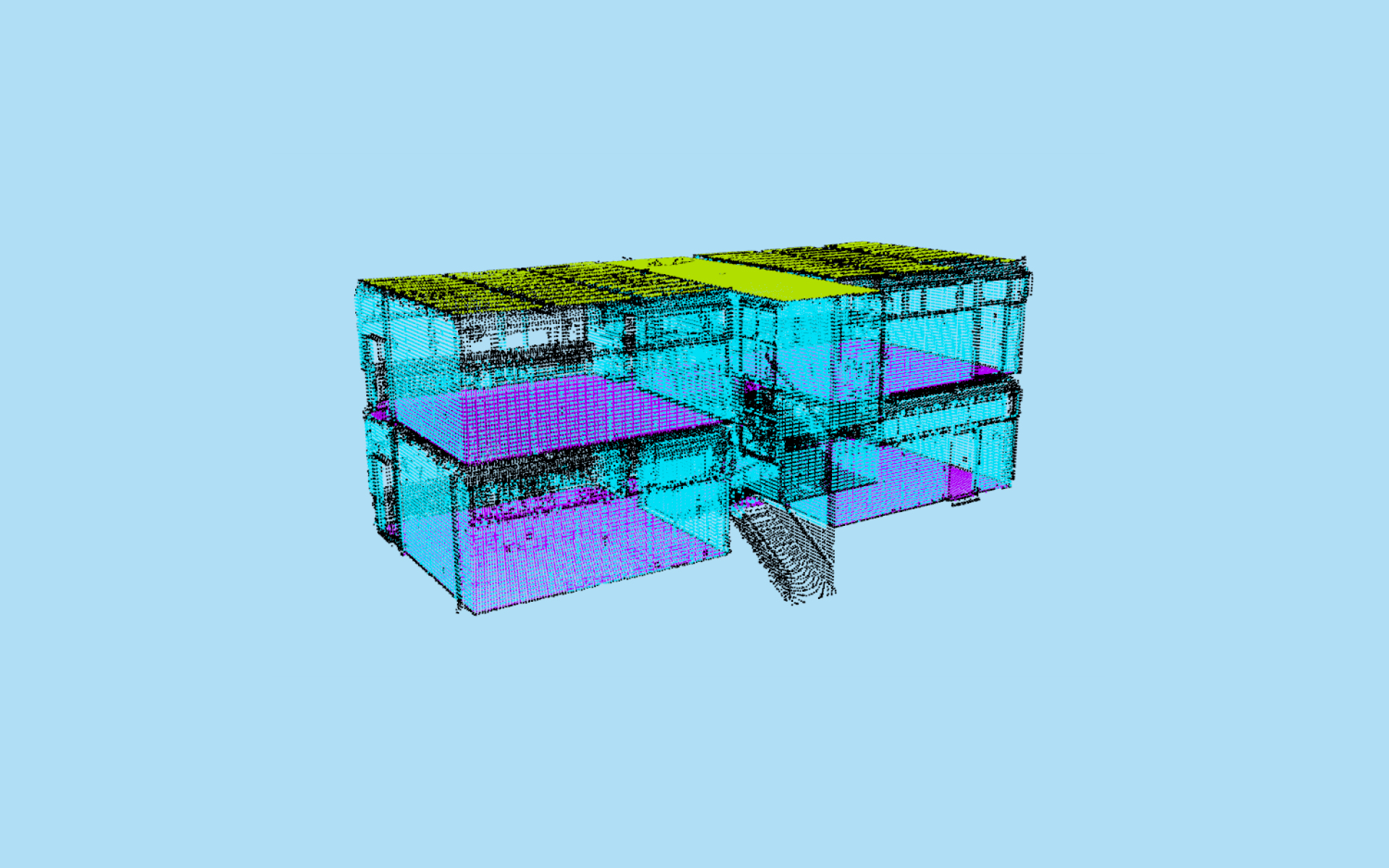

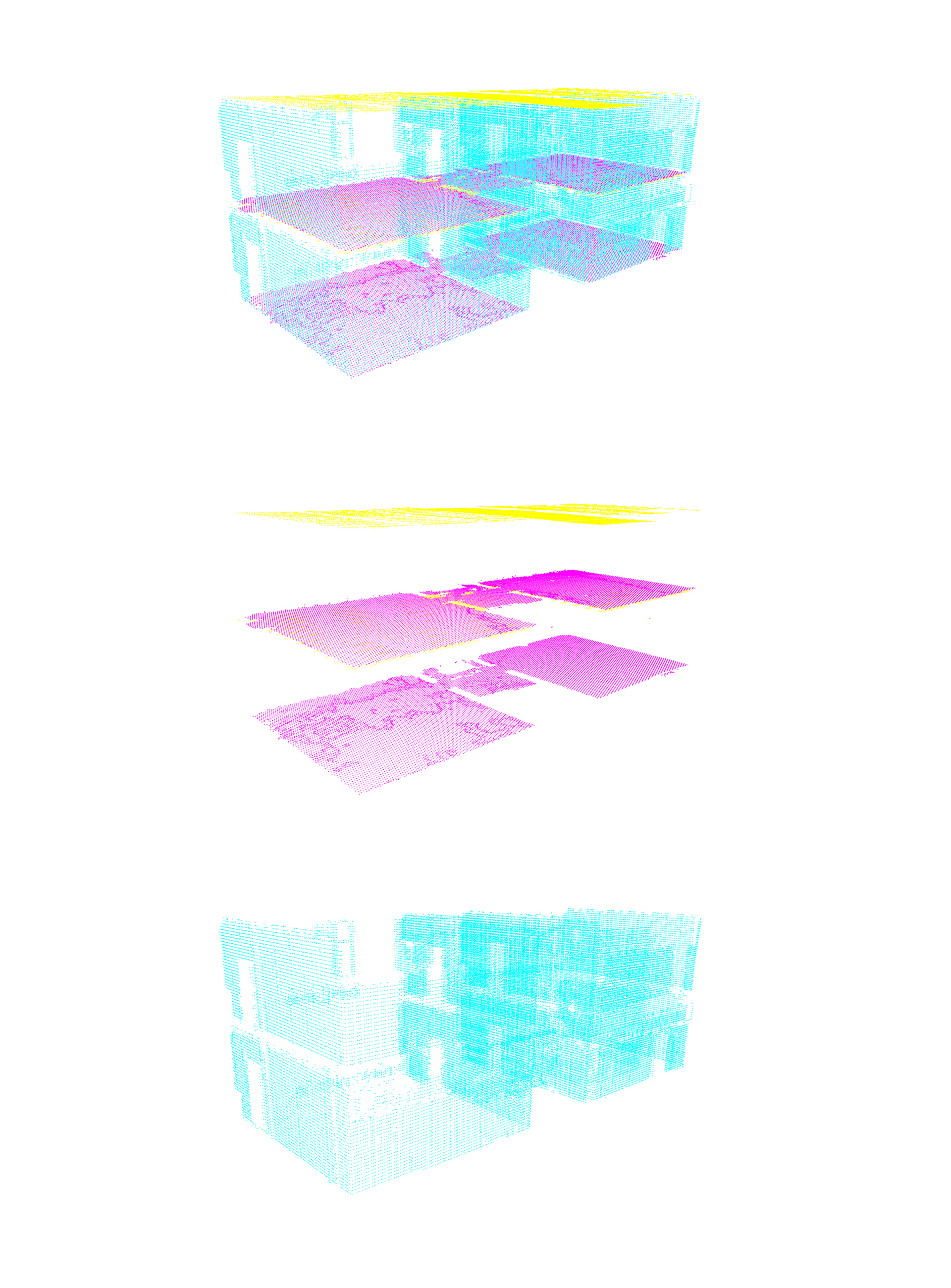

The latter was originally developed to reposition given CAD models from an assembly group (»as-designed« state) using the underlying 3D scan data (»as-built« state). The original use case was the internal structural elements of an aircraft, where parts such as furniture (seats, floor) and other components attached to the aircraft structure were disassembled. The real components were thus placed differently (»as built«) than originally planned virtually (»as designed«). This changed position had to be reflected back into the digital models. The scan data was available as a tesselated point cloud. They were of comparatively poor quality, i.e. the point density was coarse and details smaller than 10 mm were not mapped. Noise artifacts distorted the true representation of the geometry. To achieve this repositioning, the researchers used a software architecture that masters the most advanced tools in the reverse engineering process chain.

The Scangineering software’s programming is based on open-source code. The Scangineering framework can be integrated into existing software environments using optional interfaces to external software API’s. Depending on the technical use case, the software can be either open-source based or implemented in proprietary software in a suitable programming language. For use in the building sector, for example, interfaces to the proprietary software products Revit and ArchiCAD, which are widely used in architecture, are required to provide the desired front end for the end user.

The development GUI of the prototype shows what the Scangineering of buildings looks like in the application. The simple, functional user interface enables the interactive control of all required development and test functionalities. Operations for data manipulation are called up via the buttons in the upper area, after which further windows open for process control and parameter input. The structure tree displays all existing entities. The central visualizer displays 3D data graphically. Further windows for text output are used to display process information and metadata.

From Theory to Practice

The unique, hybrid approach of the project combines geometry property-based algorithms established in mechanical engineering and novel artificial intelligence (AI) algorithms. In keeping with the Fraunhofer founding spirit, the inventors of Scangineering now intend to spin off with the ARGOS project. »The approach promises enormous efficiency gains for our future customers. A big advantage here is that our partner pointreef is an established start-up and, as such, already active in the market, with an existing customer base we can draw from. In addition, we have broad backing from Fraunhofer IPK, which is actively supporting us and our spin-off plans,« says Stephan Mönchinger, who heads the project at Fraunhofer IPK.

Incidentally, those interested in mythology may already have noticed that the researchers included an allusion in the naming of the project: Argos, in Greek mythology, is a hundred-eyed giant who could look in all directions at once at any given time. Now THAT is a fitting name.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology