Reverse engineering is one of the engineering tools whose importance will continue to grow strongly in the coming years. Our researchers specialize in methods and algorithms used to automatically reconstruct CAD models with design history from scan data.

The virtualization of physical objects through 3D scanning is a fundamental part of the growing circular economy. The goal is to reuse, refurbish or recycle products.

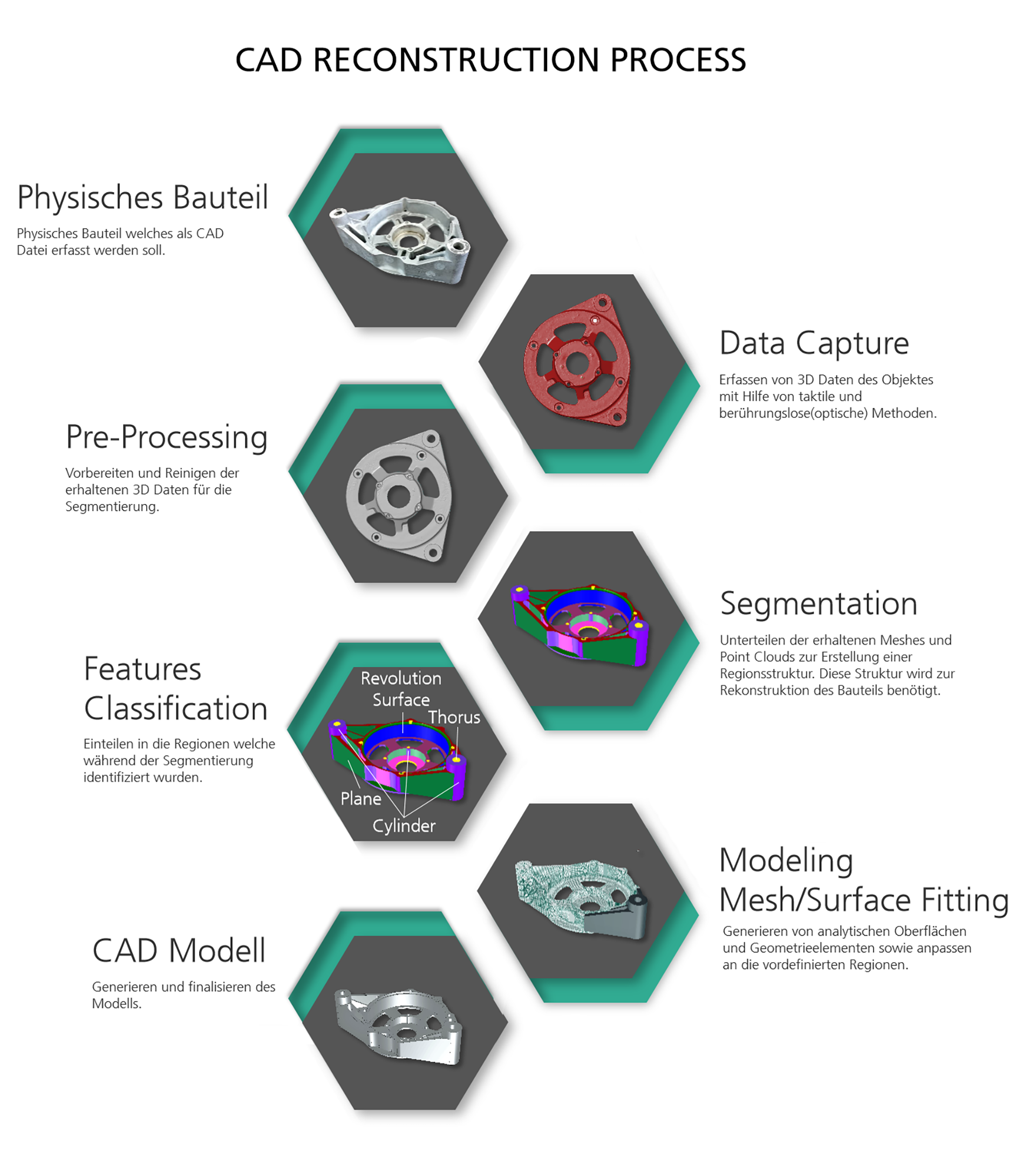

With Fraunhofer IPK's Scangineering, all sub-aspects of the reverse engineering process chain can be mapped. From data acquisition, pre-processing, segmentation and classification to final modeling.

Advantages for you:

- Modularly adaptable solutions

- Customizable interfaces

- Facilitated integration of automated processes into your engineering

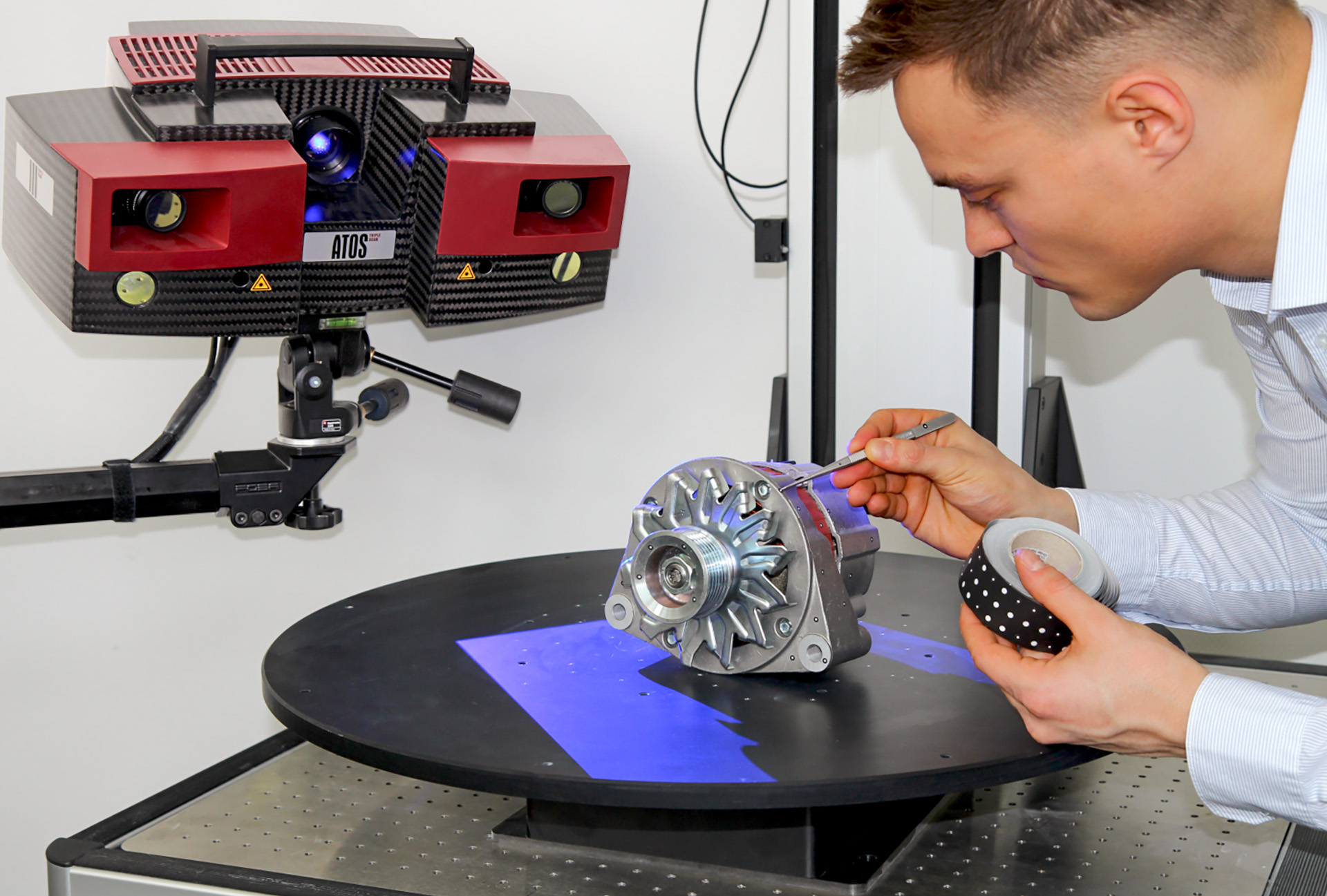

3D scanning as initial process step

3D scanning virtualizes physical objects as CAD geometries in the form of point clouds or meshed surfaces.

These input data provide real orientation and shape as algorithmically processable parameters. For example, the orientation of a virtual object in a DMU can be (re-)positioned based on the real orientation.

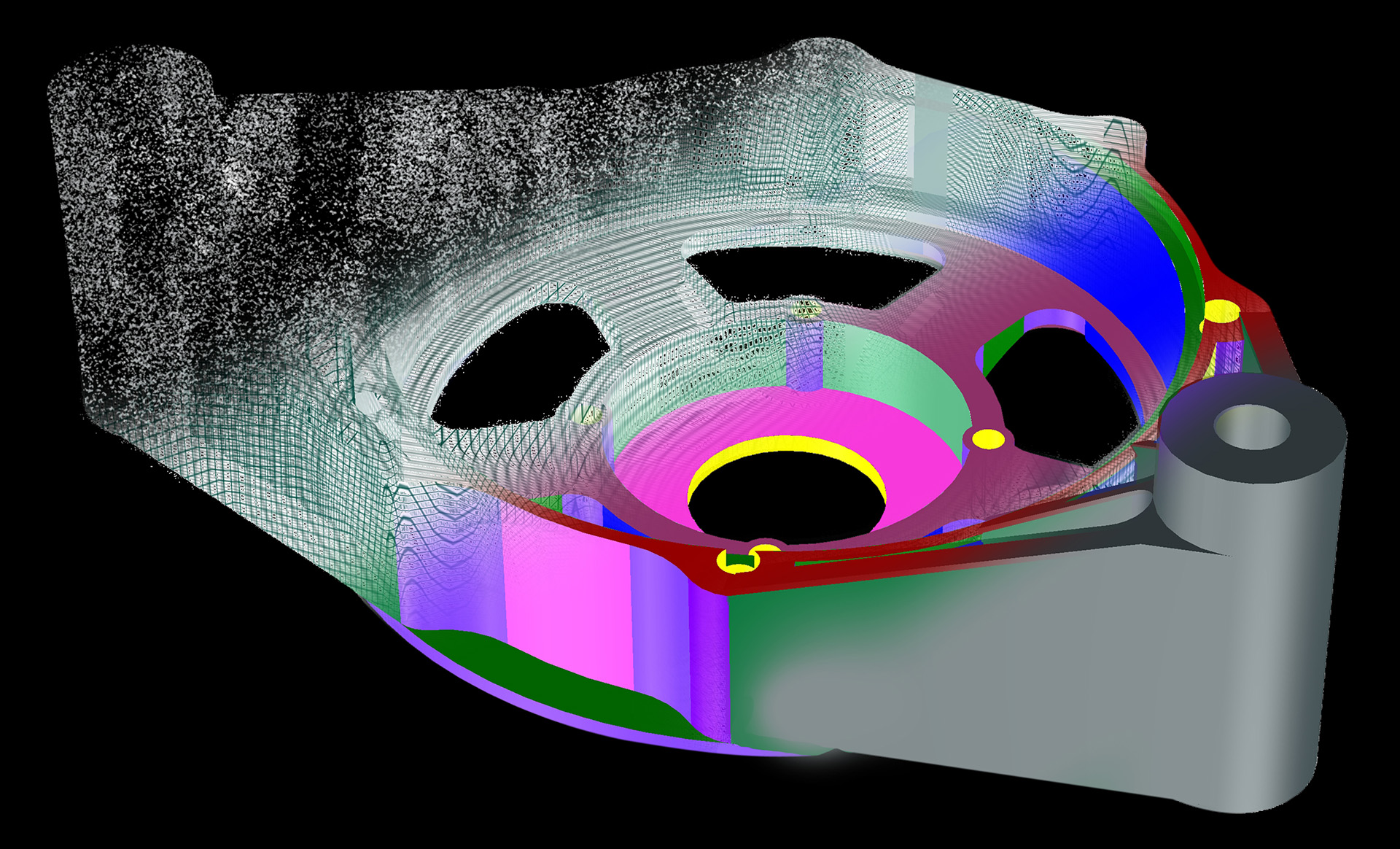

The developed algorithms are robust and are also used to segment point clouds based on geometric properties.

We have developed concepts for AI-based methods. These can be used to classify segmented point clouds and reconstruct CAD geometries.

Scangineering from Fraunhofer IPK can reduce the use of service providers who usually handle a great deal of manual processes. At the same time, Scangineering can be completely integrated into the existing software environment.

Application areas and solutions:

- Benchmark for your solution

- Concepts for data acquisition

- Automated pre-processing (reduction and meshing of point clouds)

- Segmentation and classification of point clouds and meshed surfaces

- Final feedback to parameterized CAD models

- Stand-alone software or seamless integration

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology