Ecologically Sound

Products from Makerspaces

Decentralized, flexible, individual, collaborative – these are the criteria by which modern types of production are now measured. More and more Makerspaces and FabLabs are opening up, not just in big cities but rural regions as well. These open workshops put the latest technology trends like 3D printing as well as traditional manufacturing technologies like laser cutting and milling at the disposal of a broad group of users. The participants range from private technology enthusiasts and researchers to innovation managers of business start-ups.

In German speaking countries alone, there are now over 270 such Makerspaces. The accent here is very much on trying out new materials and technologies, and doing it with like-minded people. Mistakes are explicitly allowed. But how sustainably do the users of Makerspaces and FabLabs actually work? How eco-friendly are the products, prototypes and hacks they produce?

In a project financed by the German Federal Foundation for the Environment (Deutsche Bundesstiftung Umwelt), scientists of the IWF at the TU Berlin have investigated the German maker scene and checked it for ecological sustainability. The conclusion reached by the »ecoMaker« project: Even though the scene is distinguished by its social and ecological awareness, it is still too heterogeneous to systematically funnel this awareness into local product development.

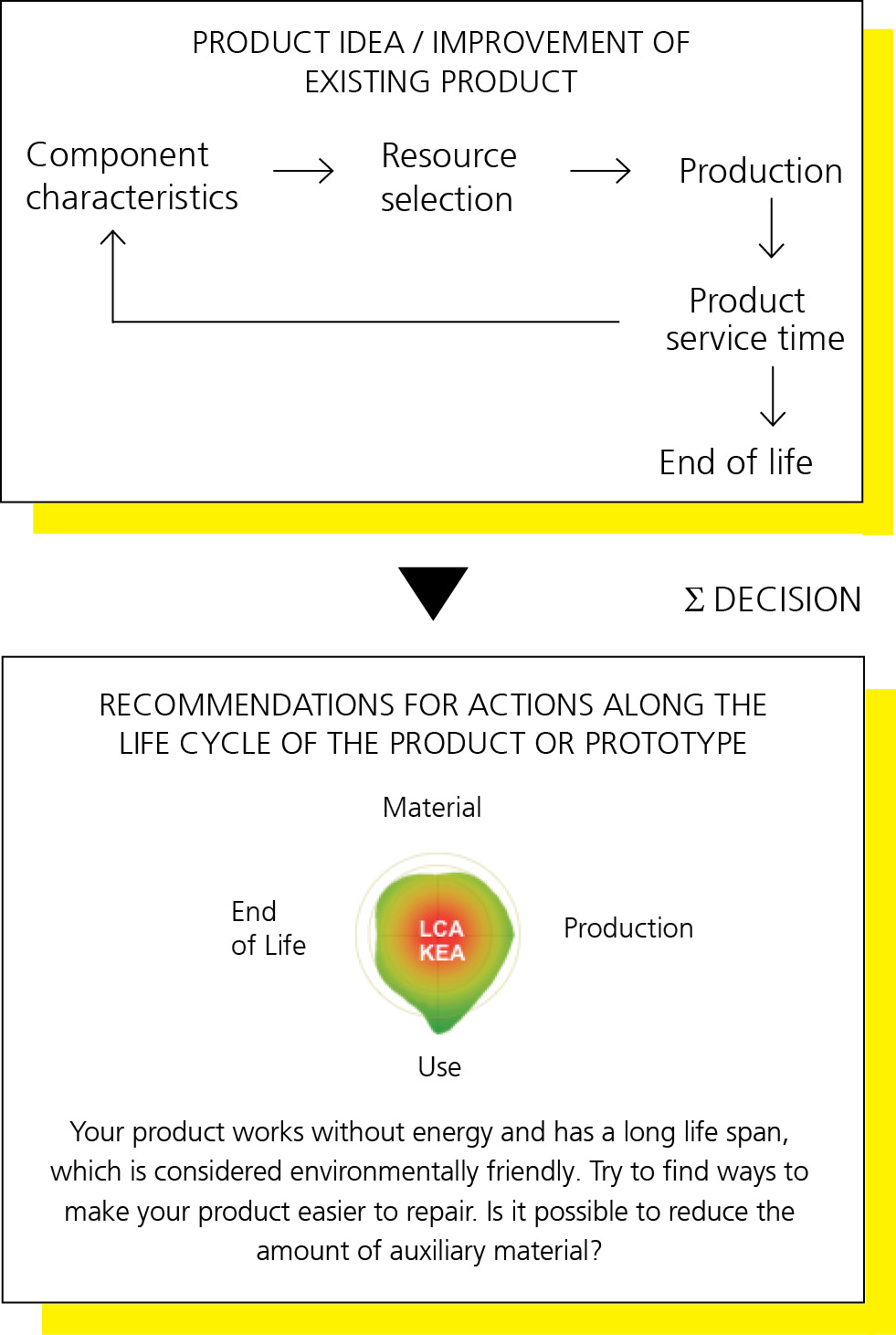

Working together with two FabLabs in Berlin and Brandenburg, the IWF experts have developed specific solutions for the establishment of methods and approaches for environmentally friendly product development in open workshops. Alongside workshops on the eco-friendly use of resources and moderated ecoMaker design sprints, a web-based product configurator should support future development of ecologically sustainable products. The ecoMaker Check allows users to conduct a simplified environmental lifecycle assessment for their prototypes or products before making them – from the selection of resources to the end of life scenario. As an outcome, they receive a prediction of its CO2 footprint.

Instructions on how to replicate products, best practice examples, and in-depth expertise are all freely available on a learning platform. This platform is designed to inspire users, but also to offer them the chance to actively present their products and have them assessed by their peers in the community. Interested parties can also visit a virtual exhibition and familiarize themselves with the most common materials and processes or explore various design approaches to the environment.

In a three months’ workshop series, the project partners have also shown how successful »makers« – the users of Makerspaces and FabLabs – can be when they tackle sustainability in a systematic manner. Two start-up teams developed and presented various products during the course of this series, from the first design concept to the final prototype. These included a modular work bench and an app for real-time tracking and visualization of water consumption.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology