Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyThe video shows how an aluminum shaft shoulder is coated with pure copper.

What is cold spray?

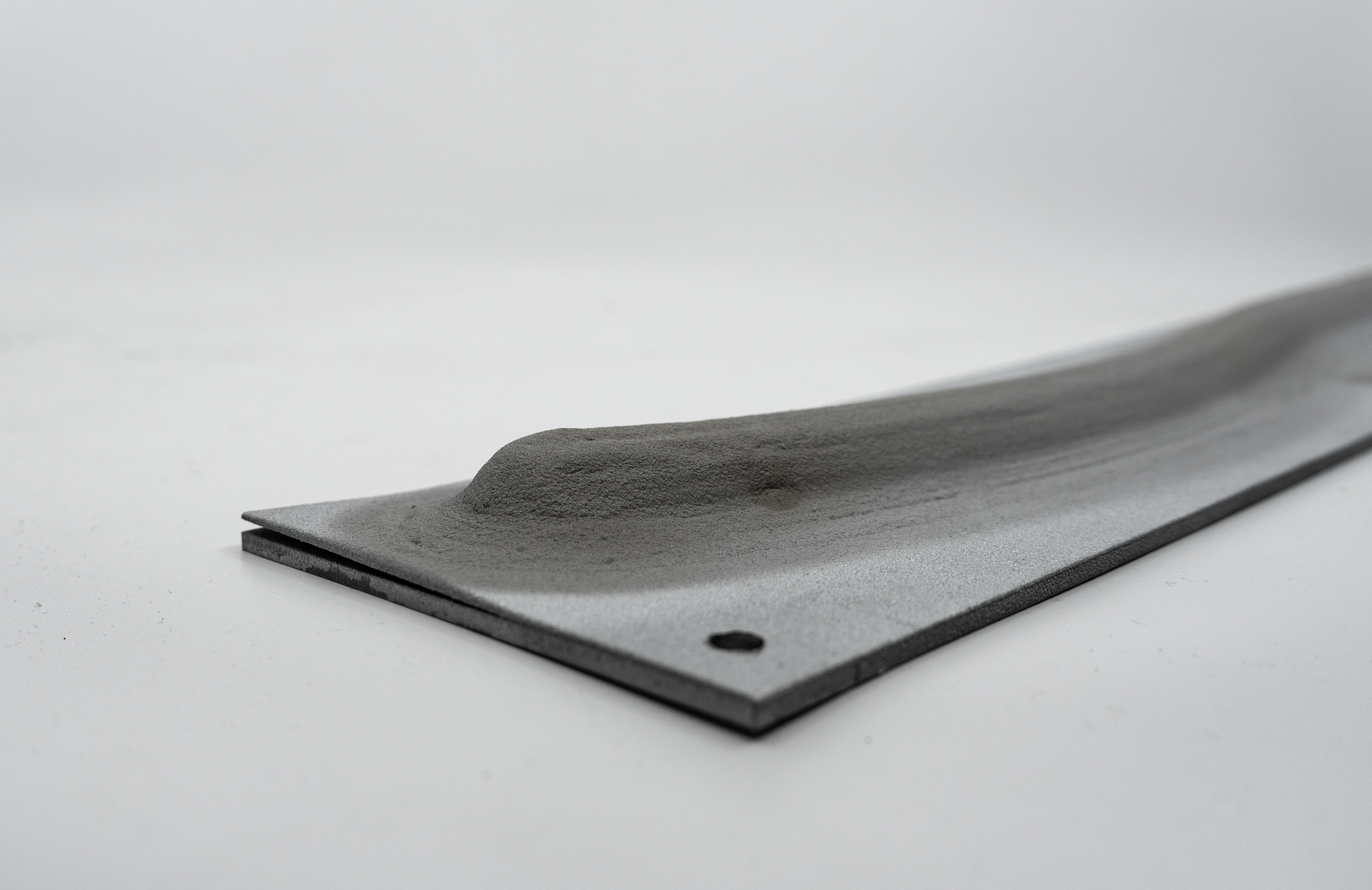

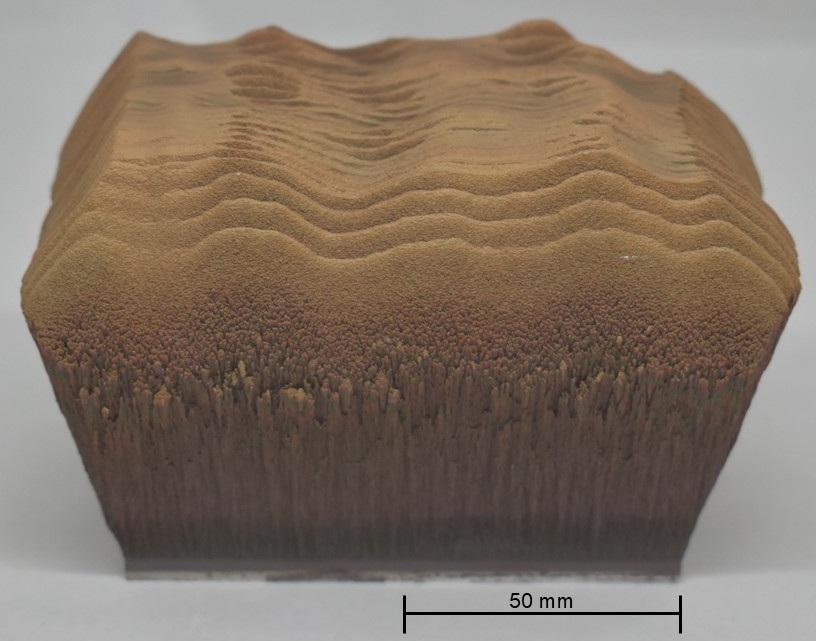

Cold Spray is an innovative thermal spray process. The technology enables the production of components and coatings without significant heat input, resulting in minimal thermal deformation and high bonding between the layers. Cold spray has become increasingly important in recent years and opens up new possibilities, particularly in additive manufacturing.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology