3D printing: correctly assessing opportunities and risks

You are faced with the question of whether and how you can use additive manufacturing technologies for your applications? We examine your use cases with regard to economic and qualitative criteria and provide a solid basis for any decisions you may want to make on behalf of your company. Be it innovative designs, the development of new materials, the search for efficient reworking processes or for economical ways of quality assurance – thanks to our broad production engineering know-how, we develop solutions that will help you advance.

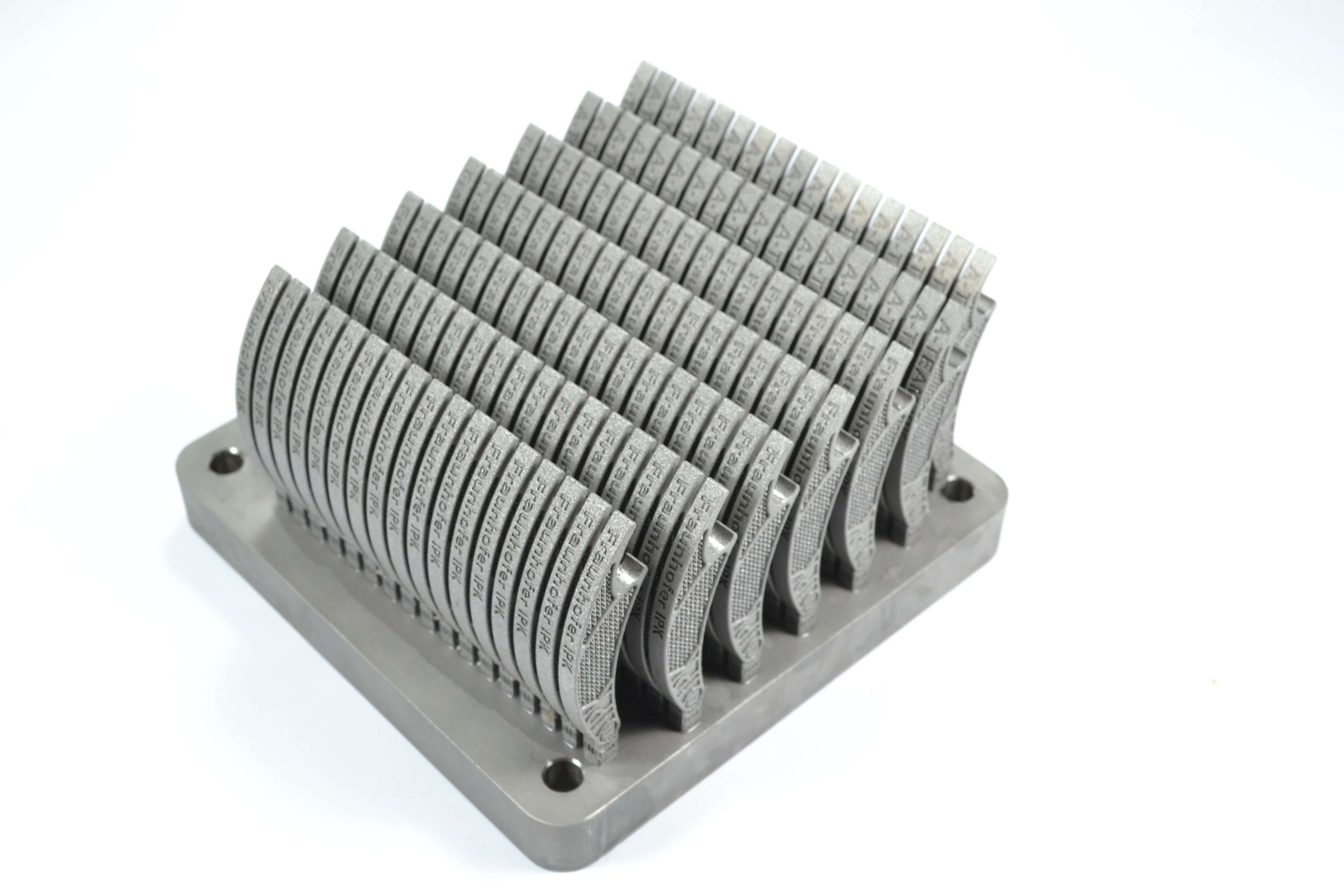

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology