From Smart to Heart

Political aggression, supply chain risks, accelerated energy transition – the global framework conditions for manufacturing companies have changed massively. This is a turning point: Today, more than ever, their ability to react in an agile way to abrupt changes is in demand. The keyword here is resilience. When acute events hit insufficiently resilient value chains, the consequences can be dramatic. Or, to put it another way: Responding to change in an anticipatory and flexible manner is a basic prerequisite for economic success today.

This is where EMOTION comes in. The new Fraunhofer lighthouse project aims to show how resilient value chains can be created through more efficient cooperation between all those involved in production. The key to this is empathy. Together, Fraunhofer IPK and six other Fraunhofer institutes will develop solutions for human-technology collaboration to support production systems in becoming responsive, adaptive and able to learn.

The researchers' assumption: It is essential for a resilient production system that all its elements – people, intelligent machines and products, as well as IT and OT systems – work together in a way that complements their expertise. This cooperation only works, if the players have a »mutual understanding « of each other. That is, if they are able to understand not only their own (production-related) state, but also the state and intentions of the other actors. The ability to build up such a mutual understanding is representative of the term »empathy«.

Copied from Humans

In the context of the project, this term is used in the production domain for the first time. In psychology, empathy describes the ability to put oneself in the position of others and to take on their perspective. Empathy makes it easier to get in touch with other people, anticipate their behavior and respond adequately to their needs. In the workplace, empathy strengthens cohesion – especially in heterogeneous teams.

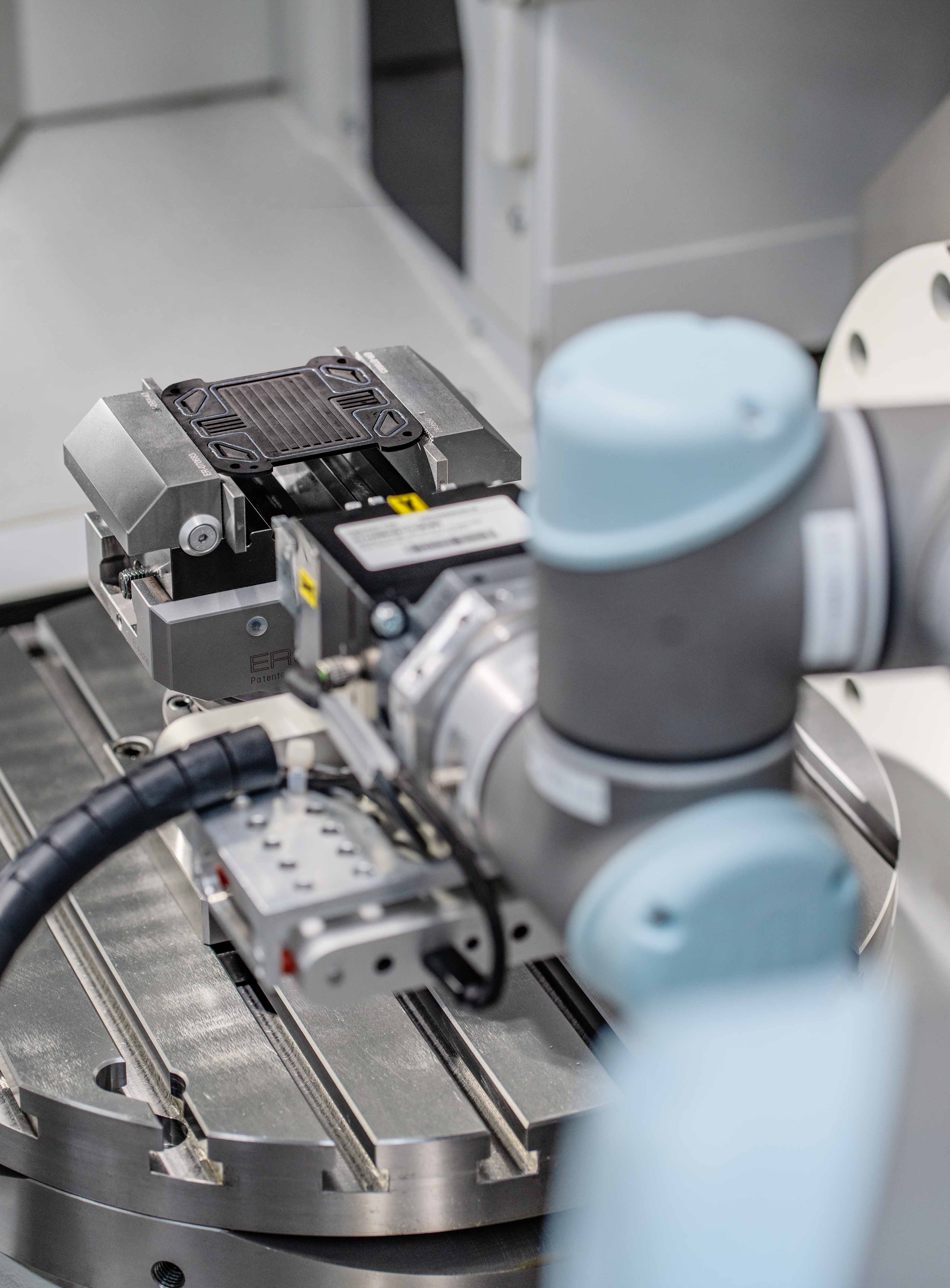

But how can these properties be applied to technology? The researchers have developed the concept of an »empathic techniaucal system«. This could be, for example, a mobile robot that is able to take on the perspective of other robots. It knows their goals, control variables and can proactively support them if necessary. To do this, it »slips« into another role and independently adapts the scope of its tasks. Another example could be a machine tool that is capable of understanding the urgency of production orders: It knows its setup status, the production specification and the expected delivery date, and autonomously coordinates workflows with other machines as well as production planning and control.

A completely empathic production system ultimately consists of networked units of such cooperative, digitally sovereign actors. Analogous to empathy in humans, empathy in production thus enables better cooperation, more predictability and, as a result, faster recognition of internal and external disturbances as well as more dynamic countermeasures.

On to the next level!

In the vision of the lighthouse project, empathic production systems embody the next technological evolutionary stage. Currently, we are at the stage of so-called cognitive production systems: By being connected to sensors and actuators and using data and AI technologies, actors are already capable of sensing their own state, interpreting ongoing processes and events, and making decisions. This includes, for example, intelligent assistance, robotics, machine and automation systems. However, in order to effectively communicate with other actors, they would require a form of information processing that includes the complete system: Mutual understanding is not possible in cognitive production systems. The great challenge is therefore to further develop cognitive systems in such a way that they are able to map cooperative behavior.

The interdisciplinary competencies of the participating Fraunhofer Institutes in the areas of production technology, smart maintenance, machine learning and Industry 4.0 offer optimal conditions for this. A decentralized system architecture that ensures the high-frequency and secure exchange of heterogeneous data volumes is elementary for the mutual interaction of the production actors. Accordingly, the project team is designing a reference model that is scalable and can be derived for a wide variety of production types. Based on this, the individual institutes will develop combined hardware and software solutions, which will then be brought together in a comprehensive platform. Finally, the added value of empathic technical systems is to be demonstrated through industry-oriented testing in three areas: assistance systems, maintenance, and production planning and control.

Empathic Assistants

Specifically, the first area of application involves cognitive and physical assistance systems that are being expanded into empathic assistance systems. These include an empathically acting exoskeleton, which recognizes – situationally and individually, depending on the physical constitution – whether an employee can perform a task such as lifting a component on his own or whether they need adaptively controlled support. The empathic-cognitive assistance system, on the other hand, automatically detects whether an employee is cognitively overloaded – for example, due to a complex assembly task under high time pressure – and then offers them specially prepared information via AR glasses, cell phone or audio assistance. If the system recognizes that the worker is returning to a productive state, it also retracts the assistance. Another example is automated guided vehicles (AGVs) for logistics and assembly, which identify transport orders on their own initiative by communicating with other actors and coordinate their activities among themselves independently.

Empathy as a Clock Generator

In the area of maintenance, anticipation is the primary feature of empathy: Since an empathic production system permanently analyzes the condition of all machines, it can act proactively. The system recognizes which machine is in danger of failing soon and also has a plan ready for which actor will take over the tasks in the short term. Since all players are aware at all times of what the most urgent goal is at the moment, they can also work together towards this goal in terms of machine utilization and wear. For example, if the on-time completion for an important customer is of supreme importance, the machines are »aware« of the urgency and adjust their control parameters accordingly. A bottleneck machine, in this case, will configure itself to avoid maximum utilization in order to prevent the risk of downtime. If a breakdown nevertheless occurs, it can take precautions together with other machines at an early stage to schedule an alternative sequence of production orders. This means that production and maintenance are no longer separate areas, but are closely networked.

Empathic, Transparent and Responsive

Linking formerly separate factory areas also affects the third area of application, production planning and control. Here, the empathic cooperation of digitally networked actors leads to a dissolution of hierarchical structures: Virtual real-time feedback from the shop floor to the planning level enables even the smallest deviations, such as a longer setup process, the delayed provision of materials, or a minimal change to the product, to be immediately detected and appropriate countermeasures to be initiated. By integrating all means of production into the digital infrastructure of production planning, a completely transparent production is created that organizes and optimizes itself independently with the help of intelligent algorithms.

These are just a few practical examples, but they already show how empathic production leads to seamless interaction between all stakeholders – and makes companies more resilient to disruptive change.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology