Producing the Future

When you imagine the ideal city of the future, what comes to mind? Green spaces between urban canyons, clean air and electric cars, all powered by alternative energy? Nothing less than a paradigm shift is needed to turn this idea into reality, since new types of power plants and electric cars will not produce themselves. Production needs to be resource-conserving and socially responsible in order to ensure high living standards without depleting the earth’s resources. The question of how we can shape Berlin’s structural transformation from a traditional industrial city to a forward-thinking technological and service hub is the guiding objective of three research projects in which Fraunhofer IPK and TU Berlin are collaborating as part of the Werner-von-Siemens Centre for Industry and Science. The interdisciplinary research teams benefit in particular from their expertise in the fields of digitalization, additive manufacturing, and artificial intelligence.

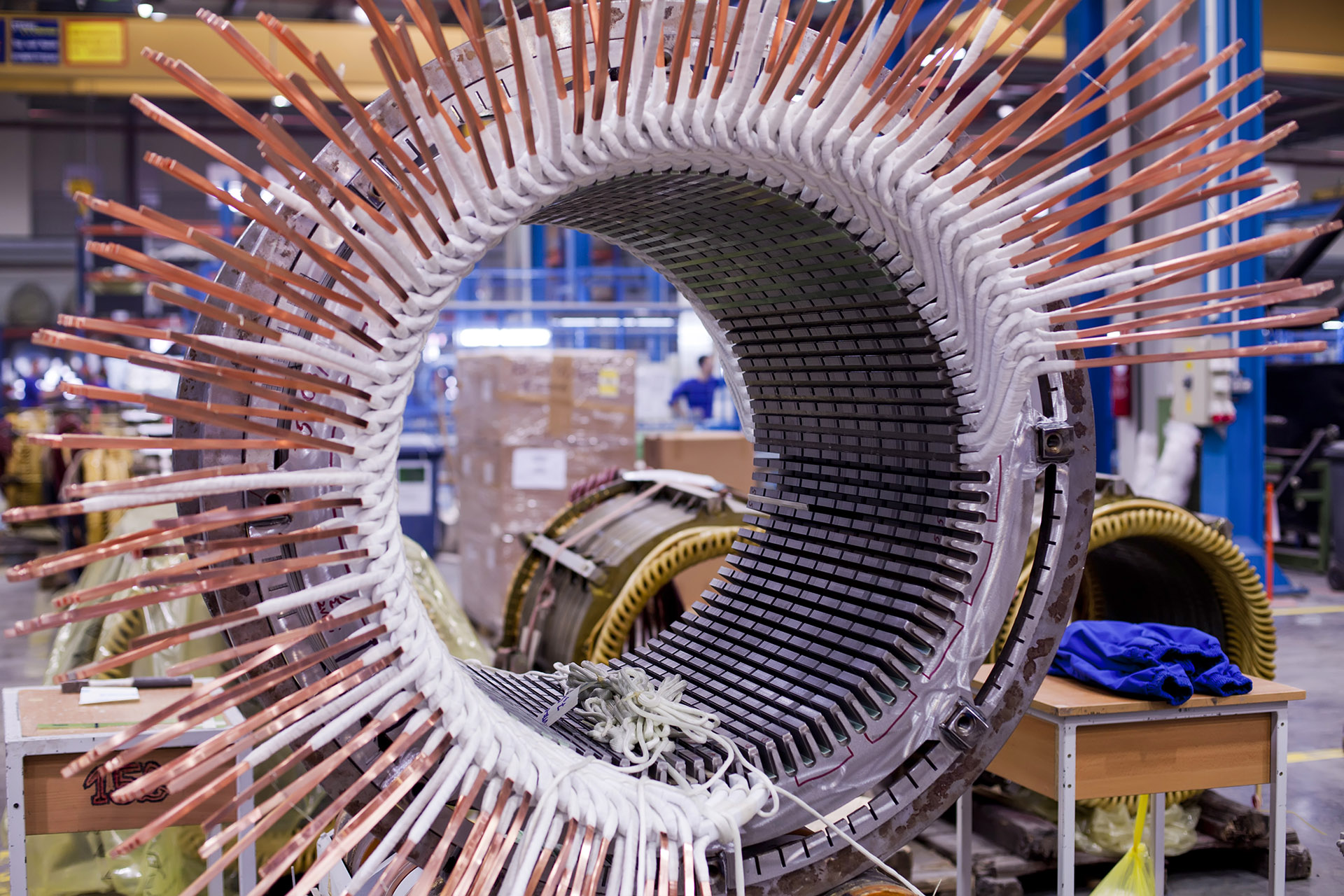

Bye-bye combustion engines, hello Electrical Drives!

In light of climate change, classic combustion engines are on their way out. They are increasingly being replaced by electrical drives. The 16 partners in the »Electrical Drives« project therefore aim to »develop the competitive electric machine of the future« and apply the research findings to related areas such as railway drives.

In order to not only go along with the transition to e-drives, but to also play a decisive role in shaping it, industrial locations such as Berlin must find disruptive approaches for designing and manufacturing electric machines from scratch. Claudio Geisert, who is working on »Smart Maintenance« in the project, is well aware of the opportunities offered by digitalization: »We see particularly great potential in AI methods. For example, we are using machine learning to turn large electric motors, such as the ones used in gas compressor stations, blast furnace blowers, and rolling mills, into intelligent cyber-physical systems that provide humans with meaningful support in their tasks and prolong the service life of the motors.«

Pascal Lünnemann also works at the interface between real and virtual worlds. In the project, he is responsible for the digital twin architecture and the feedback-to-design system. Above all, he sees digitalization as an advantage for the sustainability of production: »The production of the future will define new priorities for the sustainable use of resources. On the one hand, developers will be empowered to make sustainability-conscious decisions, while on the other, we will achieve deliberately human-centric and resource-conserving cooperation in human-machine collaboration.«

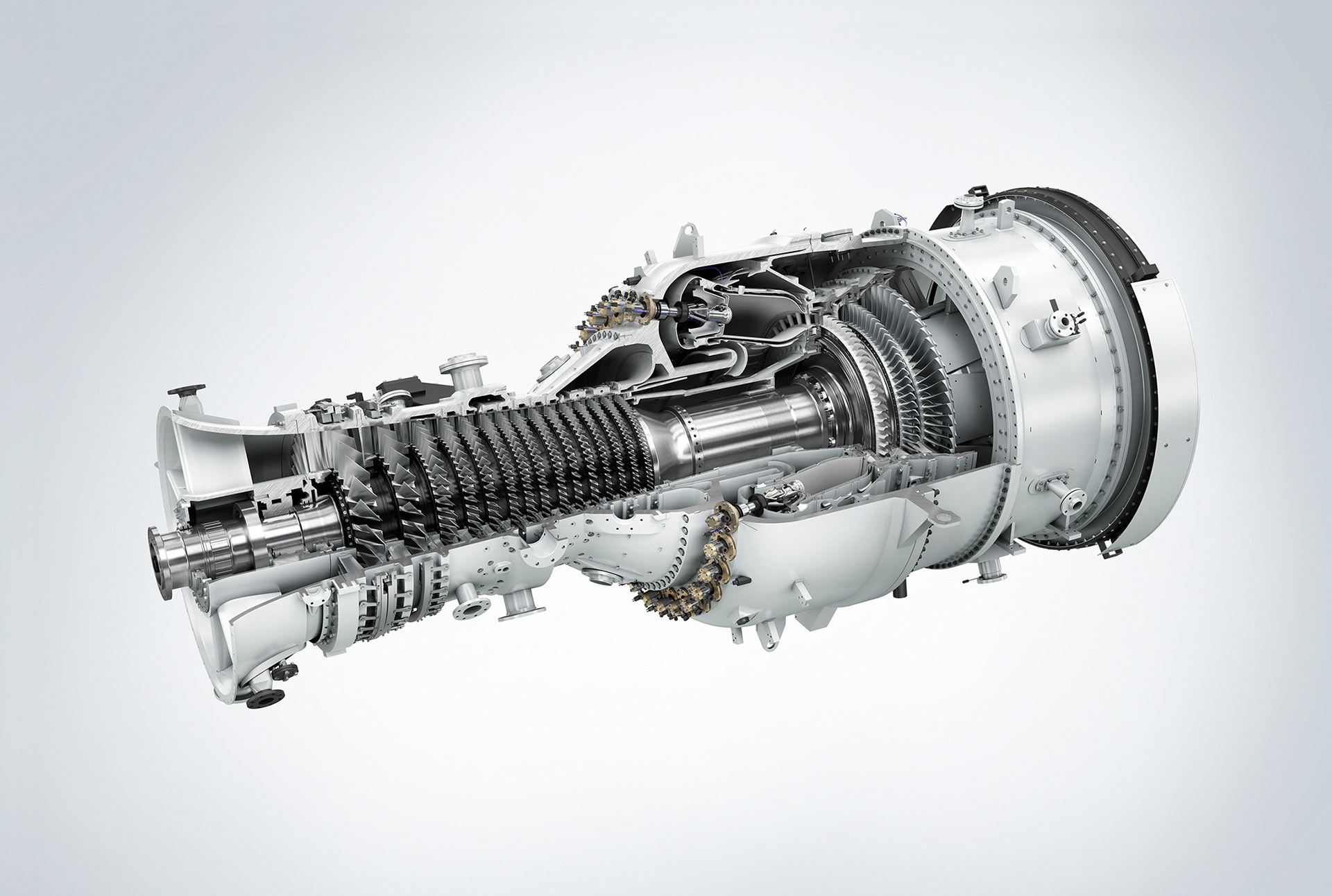

Taking additive manufacturing to new heights: High-Temperature Applications

Some components in modern gas-fired power plants come into contact with temperatures greatly exceeding 1000 degrees Celsius. But that is not the only challenge: If an increasing number of alternative fuels such as green hydrogen or biogas are to be used in the future, the components will have to exhibit entirely new properties that cannot be manufactured using conventional methods. The solution: additive manufacturing methods in combination with novel designs and materials with outstanding thermomechanical properties. With their help, the efficiency of gas turbine power plants is to be significantly increased, thereby also reducing CO2 emissions.

Dr. Kai Lindow, head of the Virtual Product Creation division at Fraunhofer IPK, describes how researchers are optimizing additive processes along the entire digital process chain: »This digital process chain starts with the digital component in the development department, then moves on to simulation and preparation for production in the 3D printing process, and includes all post-processing steps up to the monitoring of the component while in operation. The objective here is to generate a continuous flow of information. This continuous flow of information is the basis for, e.g., networking product models with simulation models which can depict the real-world behavior of printing processes. It allows the product and the process to be optimized even before the actual printing, which saves time and materials.«

Machine learning plays a key role in the project, says Lindow: »By using learning algorithms, the simulation models can be constantly improved. New products or materials can thus be realistically simulated. The better the algorithms are and the better the available data to feed them with, the closer the product and process simulations are to the actual product and process – hence contributing to time and material efficiency.«

Upgrades instead of repairs: Maintenance, Repair, and Overhaul

Maintenance and repair processes have long since exceeded their basic functionalities. The goal of this research project with nine consortium partners is to develop new technologies for maintenance and repair tasks that simultaneously include an upgrade for the serviced component.

For this purpose, new dynamic process chains are being developed in which the individual value creation steps are specified. Each component will pass through a custom repair chain. This development will be demonstrated using gas turbine blades as an example, which can subsequently be operated at higher temperatures or with longer operating intervals after the repair.

Carsten Niebuhr is working on the MRO project: »We at Fraunhofer IPK possess expertise in mechanical processing, for example in the removal of turbine blade coatings using sand or water blasting. To verify whether there is still any residual coating material on the blade, we are developing new machine vision methods. For this purpose, we use hyperspectral imaging in wavelengths that the human eye cannot detect, such as ultraviolet or infrared light.«

For the scientist, the MRO project at the Werner-von-Siemens Centre is a step toward a more sustainable industry: »In future, a fully automated repair or refurbishment line will re-process old parts for operation, allowing the life cycle of many products to be extended.«

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology