Digital (T)Wins

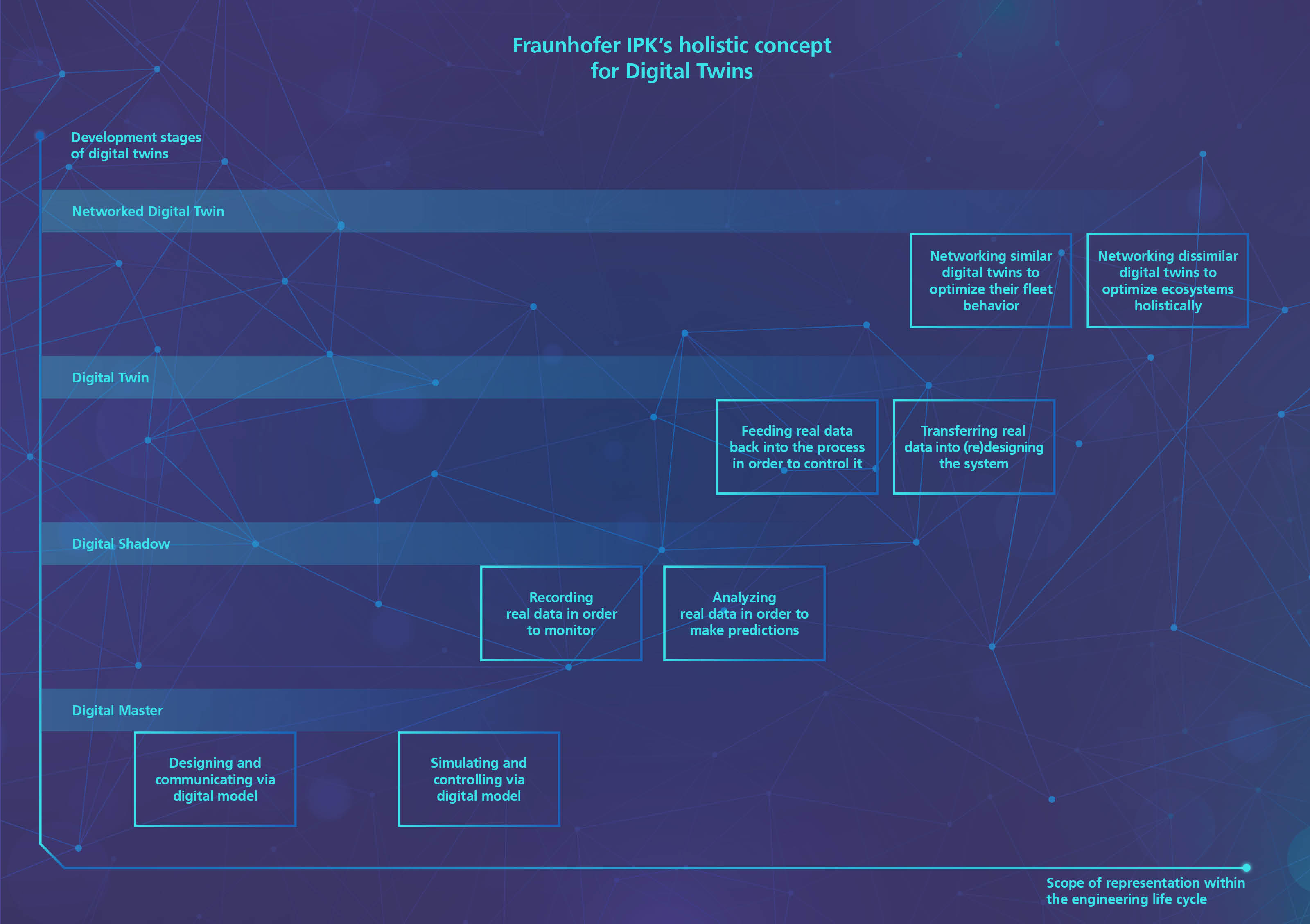

Planning highly flexible factories, realizing intelligent products and designing process parameters in machine tools – at first glance, these tasks do not have much in common. Yet they are all performed in order to engineer highly complex systems. To master them, companies are already using digital twins in many cases. They are the digital images of specific products, production plants or entire factories, and make it possible to record, predict and control their properties, status and behavior by using models, information, and data.

The basis for all this is a digital master. It holds reference models and information from the development phase of products and processes, laying the foundation for their modeling or simulation. Such a digital master can be used, for example, to define the function and design of a product or to safeguard and optimize manufacturing processes in advance.

The digital shadow, which continuously records the real-time status data of a production system, goes one step further. To this end, operational data from the shop floor is recorded, stored and made available. The behavior of a system can be observed in order to identify inaccuracies in the digital master model and correct them manually. The real data of a digital shadow thus serves as an additional basis for simulation-based investigations and helps to predict, for example, how a tool will wear out and when it will have to be replaced.

The digital twin itself is created by intelligently linking the digital master with the digital shadow. Today, for instance, vibration data can already be recorded in real time in machining processes, enabling quick adjustment of process parameters as required. Data on environmental influences such as temperature and humidity, which could negatively affect the process, are also sometimes included in order to flexibly and adaptively control the process. Typical tool vibrations during machining, which can lead to shorter tool life or even damage the workpiece, tool or machine, can thus be avoided.

The value of networking

The manufacturing industry has recognized the potential of digital twins as a future technology. According to a Gartner study, only 13 percent of all large companies with ongoing IoT projects in the major industrialized nations are currently using digital twins. For 62 percent of those surveyed, such projects are at least in the planning phase.

But in those companies where digital twins are already in use, they are far from being optimally utilized. So far, they have mostly functioned as data-provisioning systems, or they are used for backup and error analysis. This is the conclusion of the »Digital Twin Readiness Assessment« study conducted by Fraunhofer IPK and msg in 2020. Offerings such as automated value-added services and the design as autonomous or adaptive systems have so far been considered in only a few concepts.

If companies want to use digital twins profitably in their production, it is not enough to use them singularly. They only develop real potential when they are combined with each other – in other words, when they are networked twice. Not only between digital masters and shadows, but also between individual product, process or factory twins, either among themselves or with each other. In highly volatile production environments, however, this can only succeed, if this networking is used in a highly flexible and continuous manner throughout the lifecycle of production, its processes and products. The key to these so-called networked digital twins are AI solutions.

When machines help each other out

Industry and research are already working on AI algorithms that are designed to continuously and automatically optimize the control model of a machine tool. Based on empirical data from past machining processes, the algorithms learn which settings on the control model lead to optimum machining results along various boundary conditions. If the lear-ning process is successful, the adjustment of the control model is only a formality.

If the control model, and thus also the digital twin of a machine tool, is modified in this way, the same mechanisms can be transferred to other similar machines so that they can be optimized for execution in a task-specific manner, ensuring that the entire fleet of machine tools can work in perfect harmony. To this end, solutions of agent-based self-organization are applied, which make it possible to ensure that production does not come to a standstill even in the event of deviations from the original production plan. Resulting reduced process times create new opportunities in factory design or cost advantages for the product. Linking disparate master and shadow models of an overall system in the form of such a networked digital twin therefore makes sense. This way, one does not have to go to the trouble of transforming data and exchanging it between heterogeneous software systems in the production environment.

In addition, companies can apply previously simulated controls to machines and plants at distributed locations simultaneously.

Or they can use the data to implement new business models or even establish cross-company collaborations via functioning information flows.

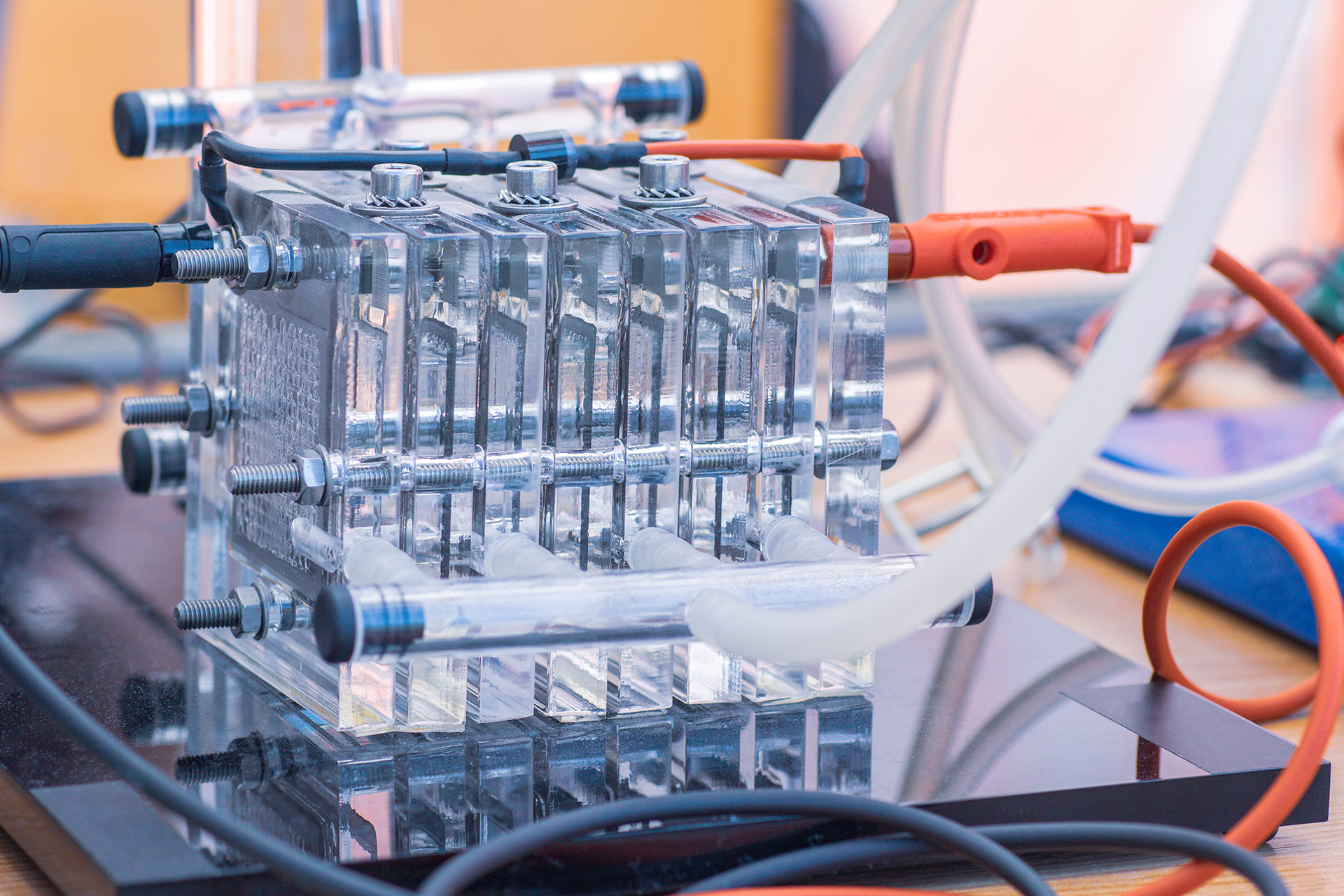

The transparent fuel cell – Cradle to Cradle

Whether for providing energy to power electric vehicles or stationary at home, the fuel cell technology is an essential part of energy transition toward decarbonization. However, the technology is still expensive and risky: investment costs for the infrastructure are high, the diversity of variants is immense (there are six different basic types alone) and the empirical values are insufficient.

For this reason, Fraunhofer IPK is developing an intelligent workshop-oriented production environment that can be used to economically manufacture very small quantities on an order-by-order basis. Each single fuel cell is to be tracked in a tar-geted and individualized manner with the help of its digital twin, so that meaningful decisions can be made along its entire product life cycle. It will be possible, for instance, to decide when the optimum time for reprocessing has come from an economic point of view, and how this can be implemented with as little risk as possible from a technical point of view.

For this purpose, the digital product twins of the fuel cells are for the first time being networked with the factory twin in such a way that the effects of changes from both the engineering of the respective digital master and the real data of the production and application can be considered together directly. The digital masters are used to network all relevant objects and processes, creating comprehensive transparency across the entire value chain in real time. Deviations from the planned production process due to disruptions are ideally detected in advance, so that appropriate countermeasures can be initiated at an early stage. The information collected and provided by the digital twins of the production systems for each process step also serves as the basis for the digital product twin of each manufactured fuel cell.

If this information is linked with that from the fuel cell's utilization phase, new insights can be gained, for example, to optimize the fuel cell on a utilization-specific basis. Such an optimization specification can then be automatically incorporated into the configuration of processes within the factory to prepare the fuel cell for its »second life«. In this way, networked digital twins are helping to recycle products economically – for an optimized circular economy.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology