Software-defined 5G Factory

The 5G mobile communications standard promises to meet high expectations in terms of the comprehensive networking of people, objects, and processes in industrial production. A higher bandwidth means faster transmission speeds that can transfer large data packets in real time. 5G enables robust, fail-safe communications for networking intelligent machines and devices in the Internet of Things (IoT) and the implementation of distributed production. This will allow industrial production and service processes to be carried out more effectively and efficiently.

Testing future technologies live

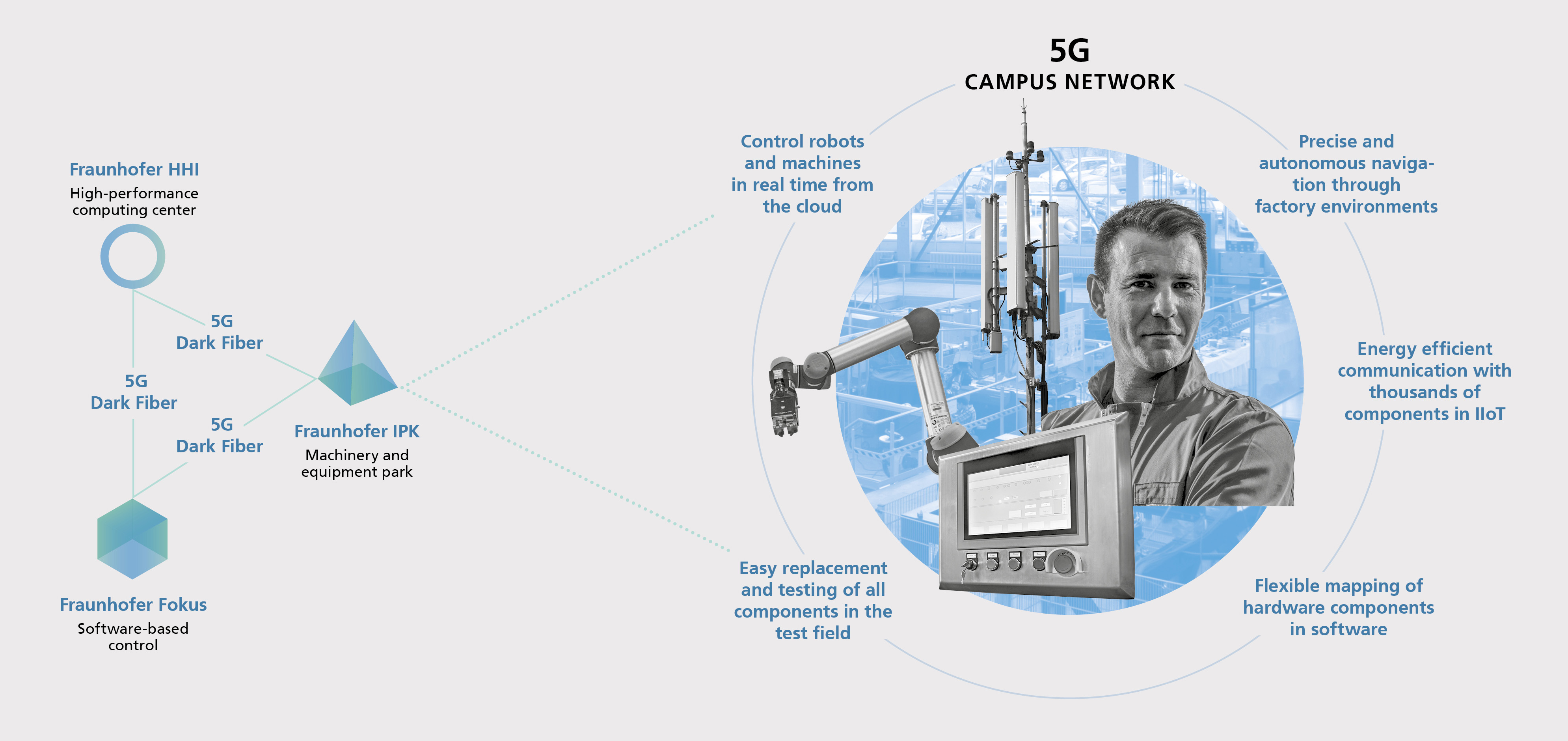

At the Berlin Center for Digital Transformation, the four Berlin-based Fraunhofer Institutes are jointly researching the development of future communication technologies in various fields of application. For this purpose, Fraunhofer FOKUS, HHI, and IPK are networked via a dark fiber optical network and a 5G radio link. Using this communications infrastructure with real-time capabilities, the software-defined 5G factory, in which all aspects of factory operations will be implemented, will be configured by the end of 2020.

Perfectly networked and optimized in real time

Fraunhofer IPK will directly be providing this infrastructure with the latest machines and robots from its experimental field, while older machine tools will be integrated subsequently via sensors and communications modules. This retrofitting is being developed by Fraunhofer IZM. The systems’ software can be controlled both locally at Fraunhofer IPK and remotely from Fraunhofer FOKUS. A high-performance computing unit (HPC) at Fraunhofer HHI will perform computationally profound tasks and provide analysis results to the control software in real time. Coupled with process management systems, this creates a real-time cockpit that controls production processes variably and according to specific situations. The software-defined 5G factory of the Berlin Center for Digital Transformation has been designed as a test field for industry. Every component of the 5G infrastructure is interchangeable and can be replaced with custom-developed components such as antennas, software modules, or sensors. Using predefined factory processes, companies can test the functionality of their components in a real environment and verify their impact on the 5G infrastructure.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCheck out Fraunhofer FOKUS' video explainer about the Fraunhofer 5G campus network and how it connects to our own 5G infrastructure for a combined, multi-vendor network that enables our research in the field of Industry 4.0.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology