Exploit, Manufacture, Repeat

Prosperity has its price. The consumption of resources is rising along with the living standard of many people across the world. Highly industrialized countries have a particularly poor record: Every German consumes on average 16.1 metric tons of raw material each year. That is twice as much as the global average and at least ten percent more than the European average. At the same time, we Germans are producing 412 million metric tons of waste a year. That boils down to nearly five tons of trash per person.

The End of the Road

In global terms, these worrying trends are continuing to increase. Developing and threshold countries are mainly banking on growth through industrialization, using the same means as previously industrialized nations to give their growing populations an acceptable living standard. Given the present state of production technology, just the production of steel, aluminum, plastic and cement in the 21st century will cause around 800 gigatons of CO2 emissions. This means that emissions from these four material streams alone would be the equivalent of all the emissions permitted by the global effort to achieve the two degree goal.

Science, government and civil society are now confronted with one crucial question: How do we maintain our present level of prosperity without denying future generations the basis for a life worth living?

The Circular Economy

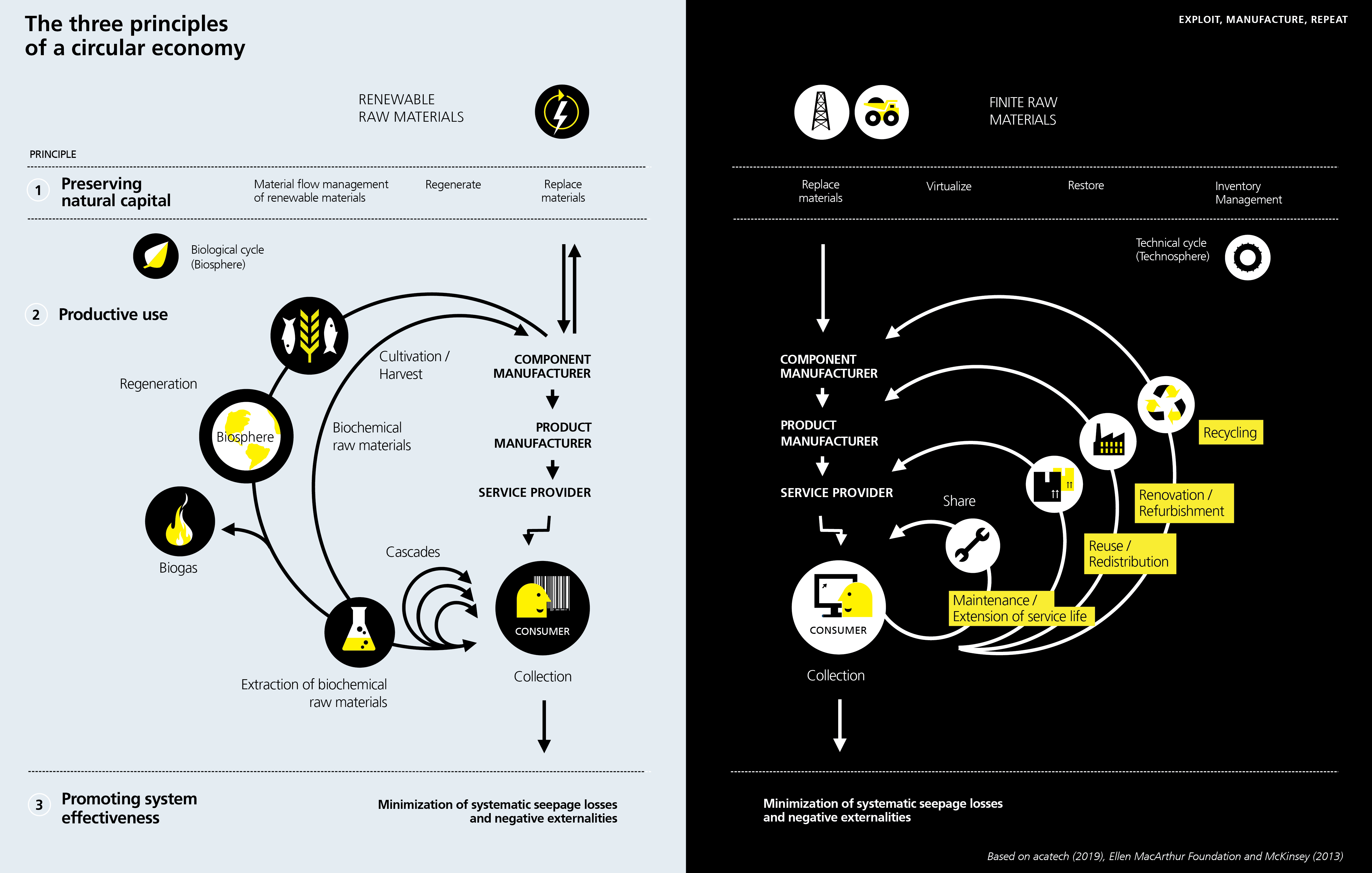

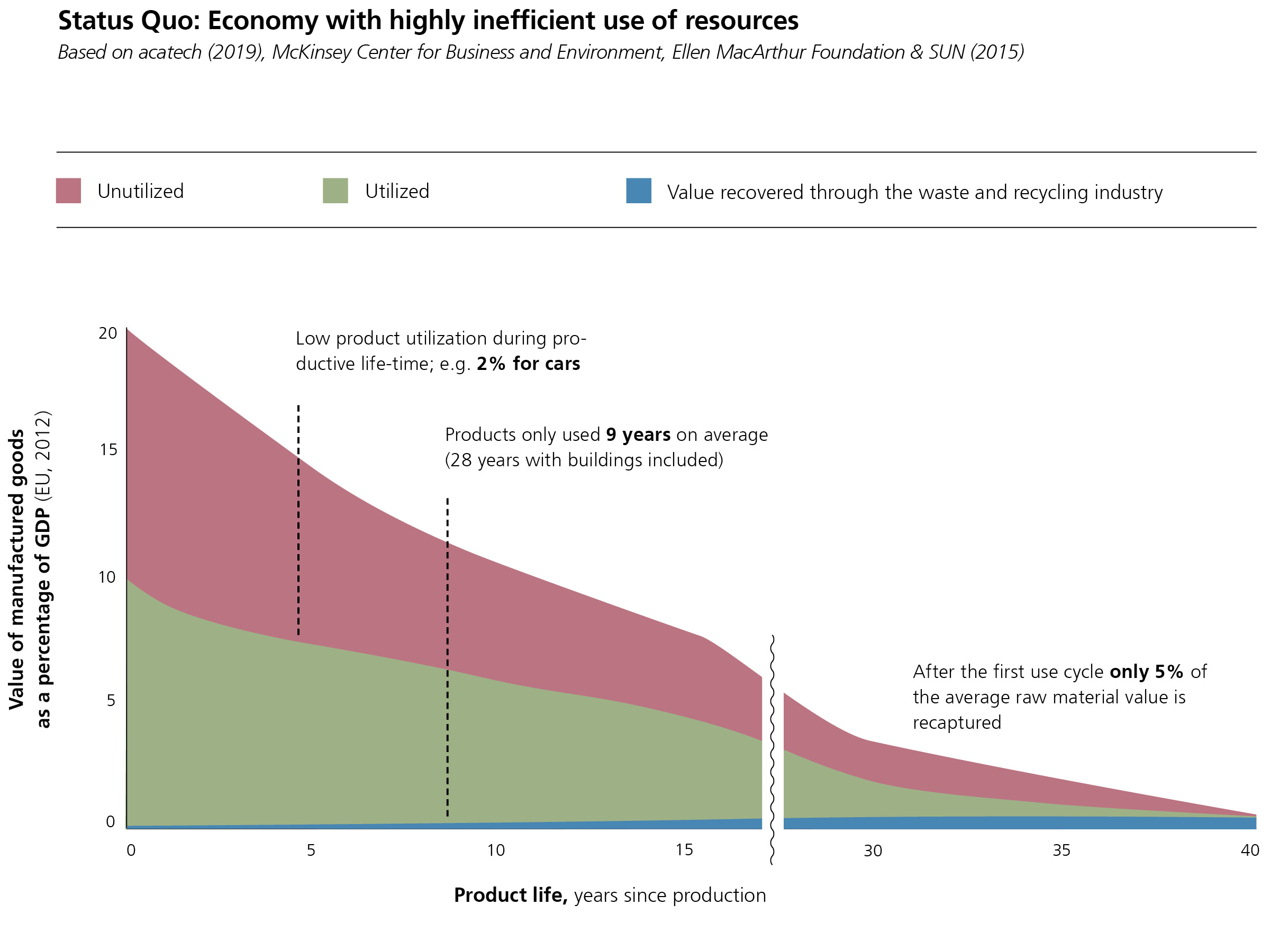

One of the main reasons for both our enormous consumption of resources and the enormous amount of waste we produce is our linear economy. We take raw materials and use them to make goods, which we then dispose of. If we are to hit our global sustainability targets, we need to rethink this process. Efforts to do so have given birth to the concept of the circular economy.

The circular economy is a regenerative system of production and consumption. Within this system, energy and material loops are slowed down and closed to reduce consumption of resources and energy while at the same time producing less waste and fewer emissions.

The idea is to make more efficient use of raw materials and recycling them in a loop, so that they remain valuable to us for as long as possible. Only if we succeed in recycling used materials in such a loop can we decouple consumption of resources from economic growth in the mid-term – which would not only help the environment, but also facilitate greater prosperity for more people.

Initiating the Transition

To develop a systematic approach in a macroeconomic context, the National Academy of Science and Engineering (Deutsche Akademie der Technikwissenschaften – acatech) launched the Circular Economy Initiative Deutschland in 2019. Financed by the Federal Ministry of Education and Research (BMBF), this initiative seeks solutions to the question of how we can effect a systematic transition from a linear to a circular economy in an interdisciplinary and interdepartmental dialogue between scientists and representatives of industry and civil society.

Both Fraunhofer IPK and the Institute for Machine Tools and Factory Management IWF of the Technical University of Berlin are part of the conversation, which aims to draw up a roadmap that will describe a model for circular value creation. On a less abstract level, it should also contain long-term goals for raising resource productivity. Lastly and most specifically, the roadmap should identify suitable tax measures to establish a substantial circular economy.

The process of remanufacturing or refabrication, as it is also referred to, can serve as an example to show what a real-life circular economy could look like. In principle, this simply refers to the idea of repairing or refurbishing a used product in order to restore it to its original quality. A great part of the raw material and energy can be saved, that would have been necessary for manufacturing a new product.

Apart from the additional opportunity of being able to offer cheaper spare parts and replacements – thus prolonging the lifecycle of the product – closed-loop circulation of raw materials also offers considerable savings in terms of CO2 emissions. In spite of the obvious advantages of remanufacturing, even in developed markets, remanufactured goods rarely exceed five percent of overall merchandise. This holds true even with product families that lend themselves to such a method like smartphones, household appliances or machine and plant components.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology