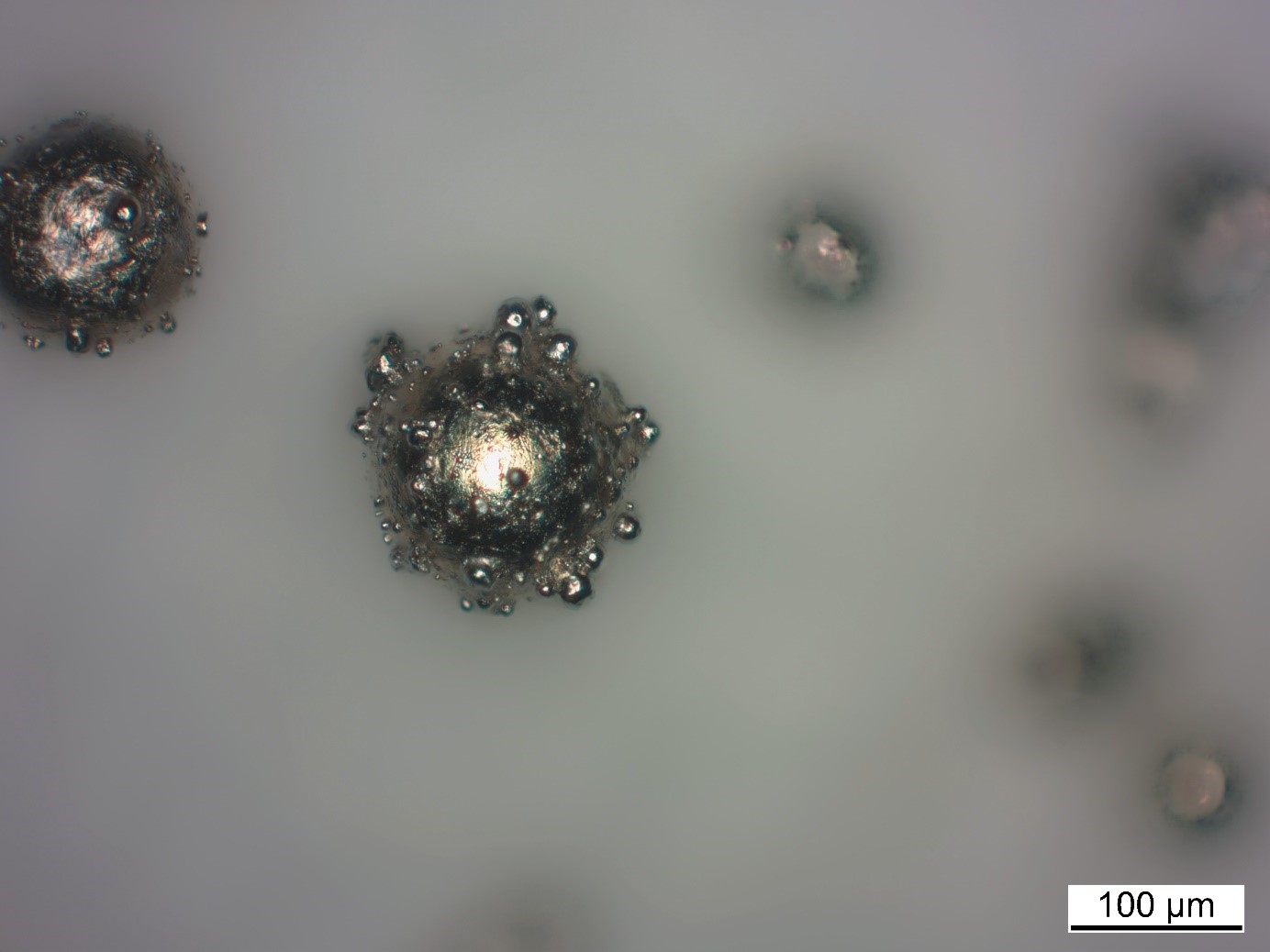

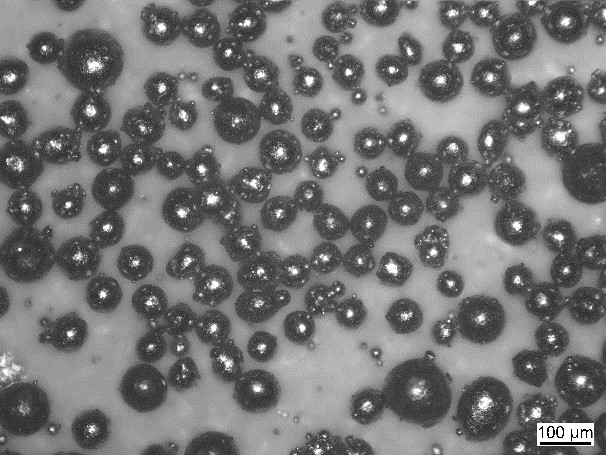

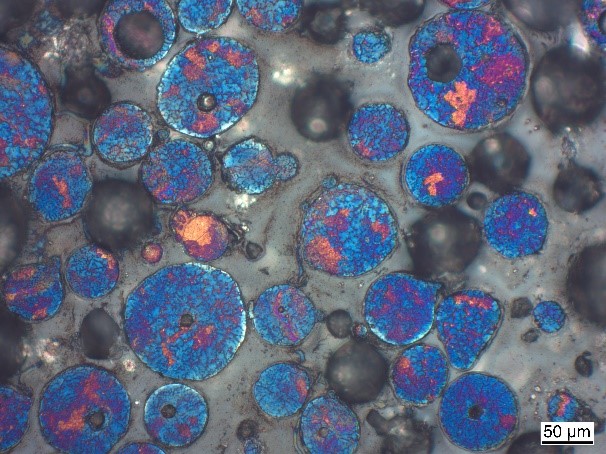

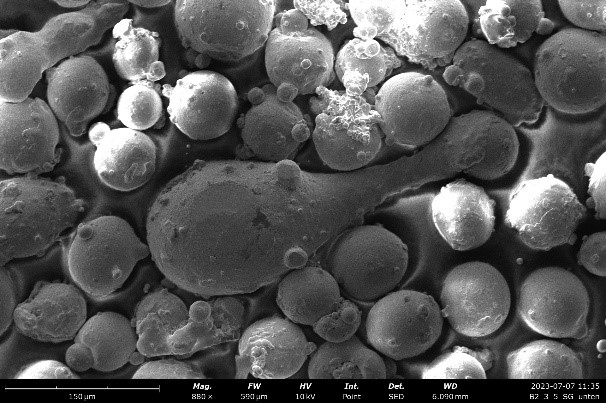

Additive manufacturing processes enable the production of complex components with high precision. At the same time, they save material compared to machining processes. The quality of the materials used plays a critical role. The metal powders used have different properties, which have a direct influence on the processing, the results and therefore also on the reproducibility in additive manufacturing. Reproducibility is a major challenge in additive manufacturing.

Powder analysis helps to understand the causes and correlations between powder quality and process behavior and thus to optimize the additive components and coatings to the desired quality level. We can help you bring your additive components and coatings to the desired level.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology