What is handheld laser welding?

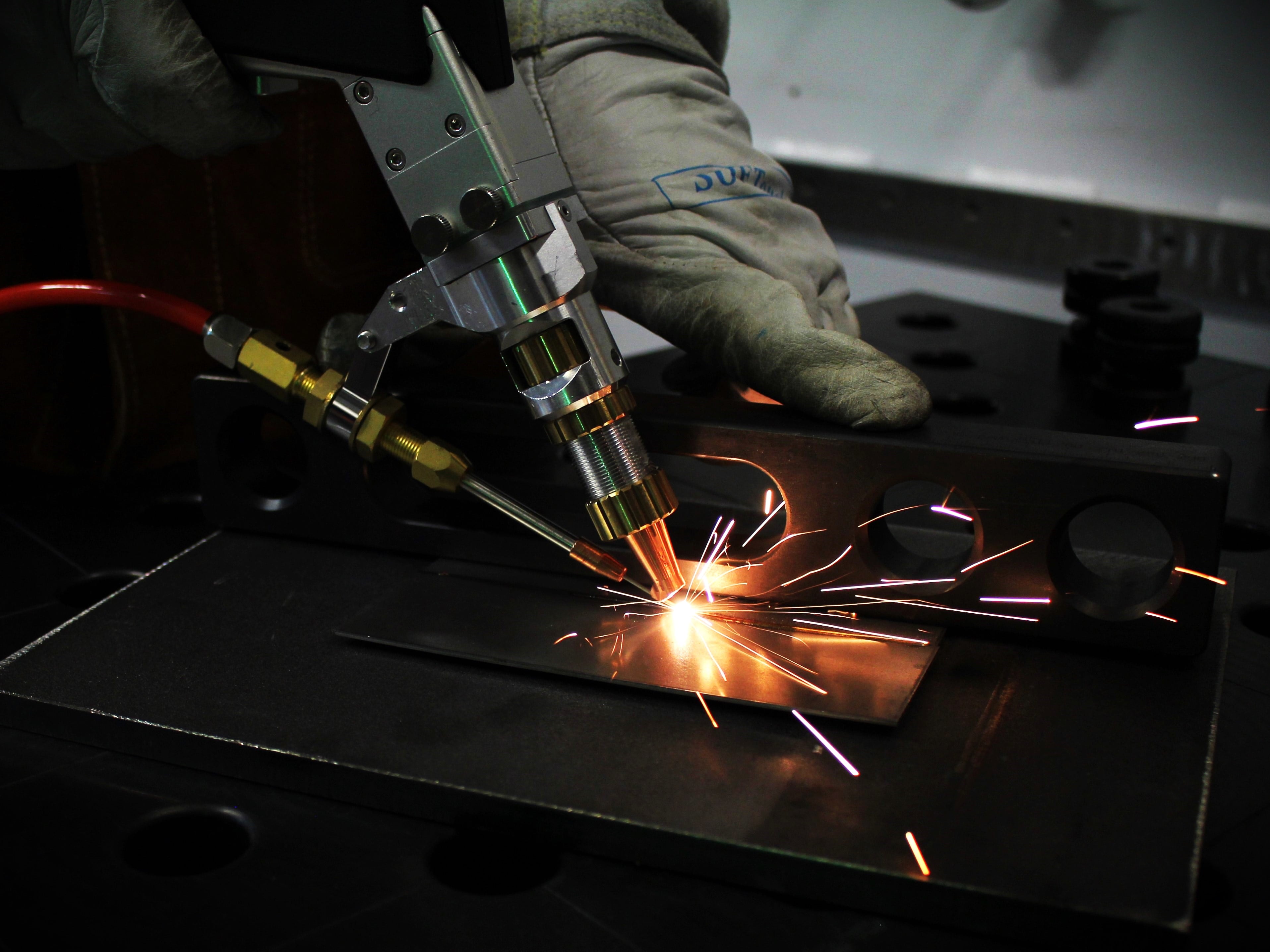

Handheld laser welding, manual laser welding, is a process that is increasingly being used in industry to join thin sheets with minimal distortion. In this manual process, the operator guides a welding gun along the edge to be welded. The energy source is a laser, which is shaped by optics into a line or other defined figures. Depending on the application, a filler wire may also be used. The weld bead is protected by a shielding gas, usually argon or nitrogen, which flows parallel to the laser.

How does handheld welding work?

Handheld laser welding is particularly suitable for applications that require high welding precision, minimal distortion or thin sheet thicknesses. As a manual process, it is primarily used in custom manufacturing and for small batch sizes, such as in vessel construction. The laser can be used to quickly and easily join unalloyed, low alloyed and high alloyed steels, as well as aluminum and nickel-based alloys. Titanium and copper alloys can also be processed. Typically, T-, overlap or corner joints are welded, but I-joints are also possible. The depth of penetration varies depending on the material, the joint type and process parameters, especially the maximum laser power of the machine.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology