What is special about the Fraunhofer IPK automation assessment?

The on-site analysis of automation potential carried out by our experts is based on

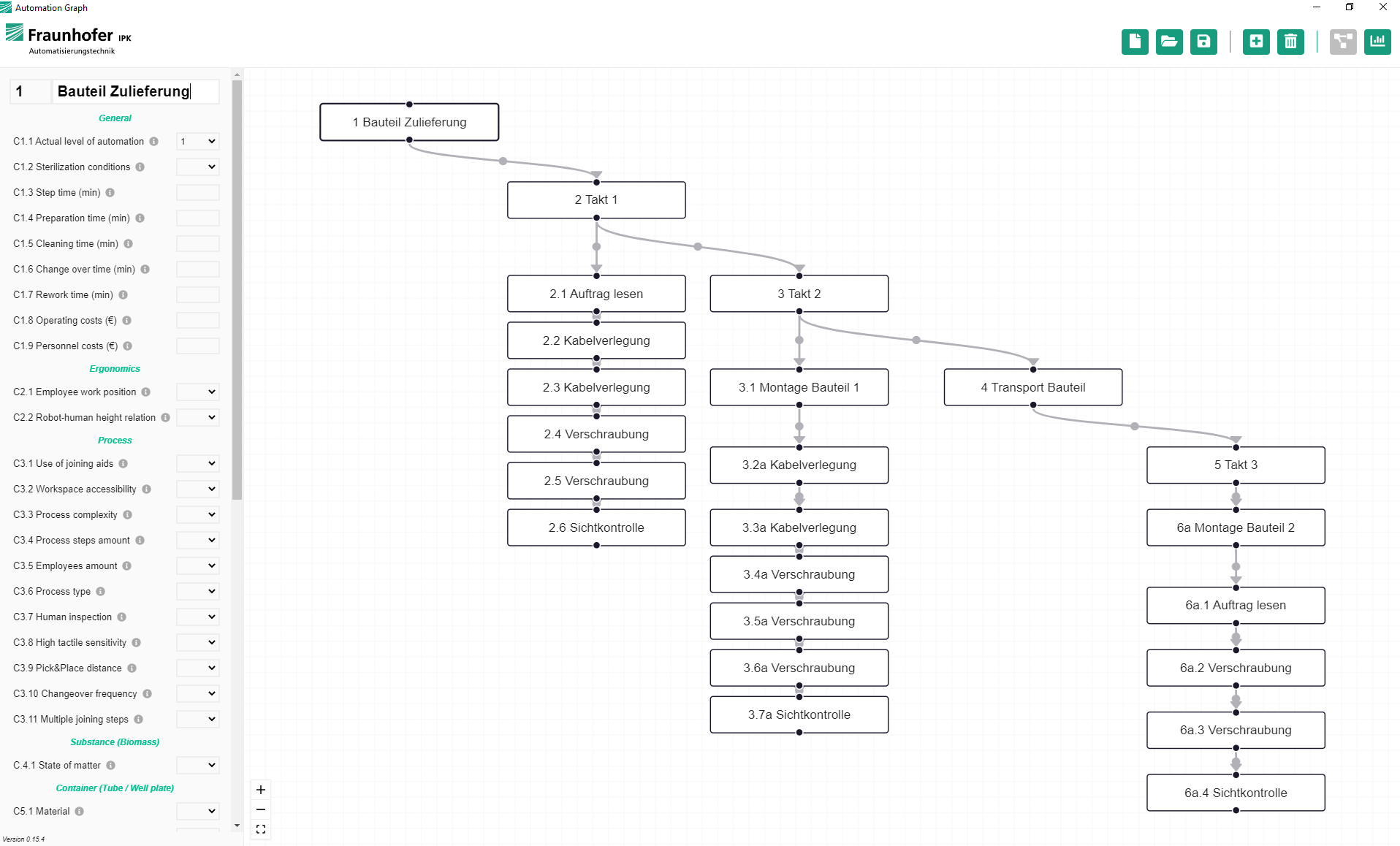

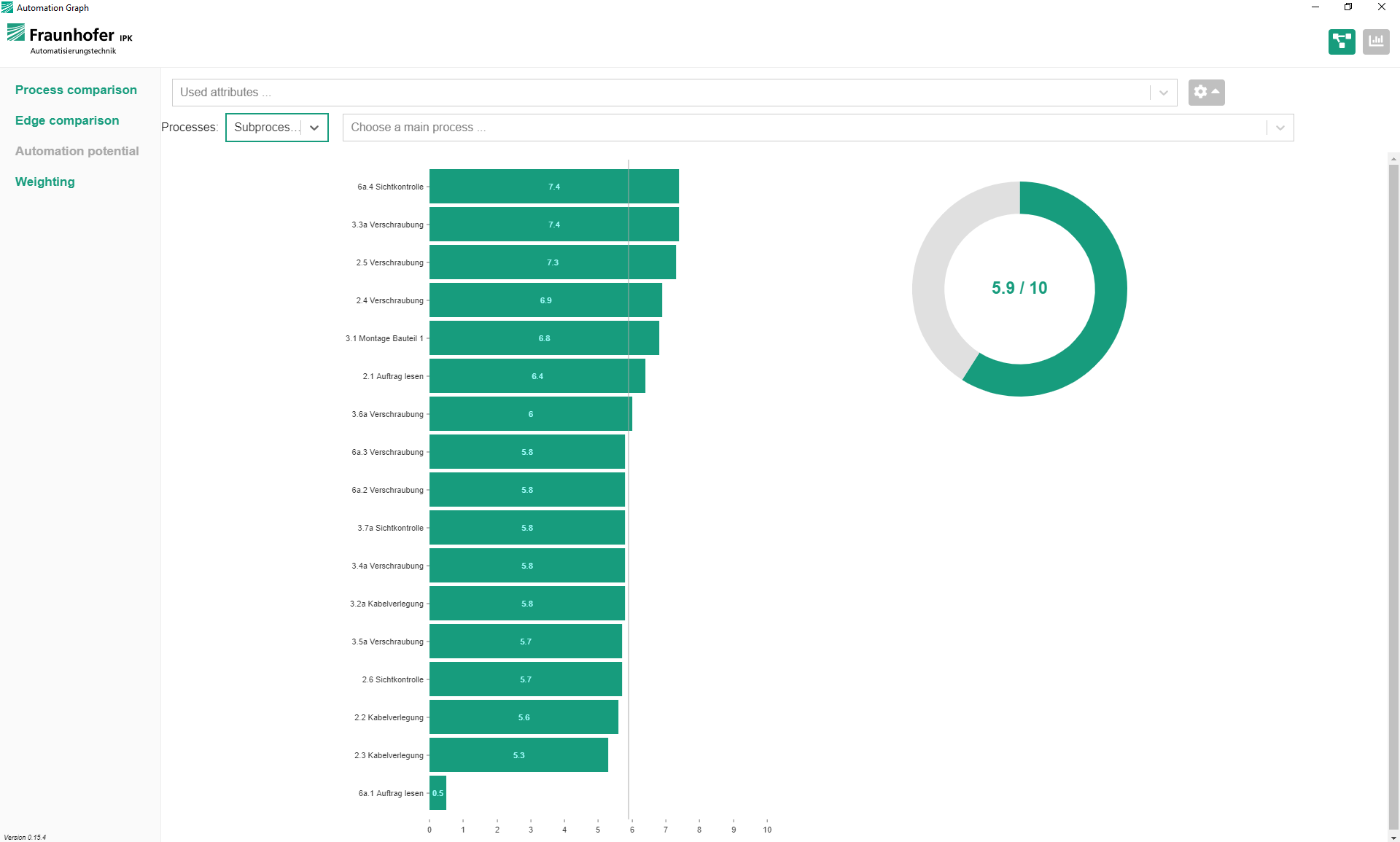

- capture of production processes through an attribute-based method

- representation of these attributes for the individual process steps

- quick and easy adaptation of the evaluation methodology to your production processes

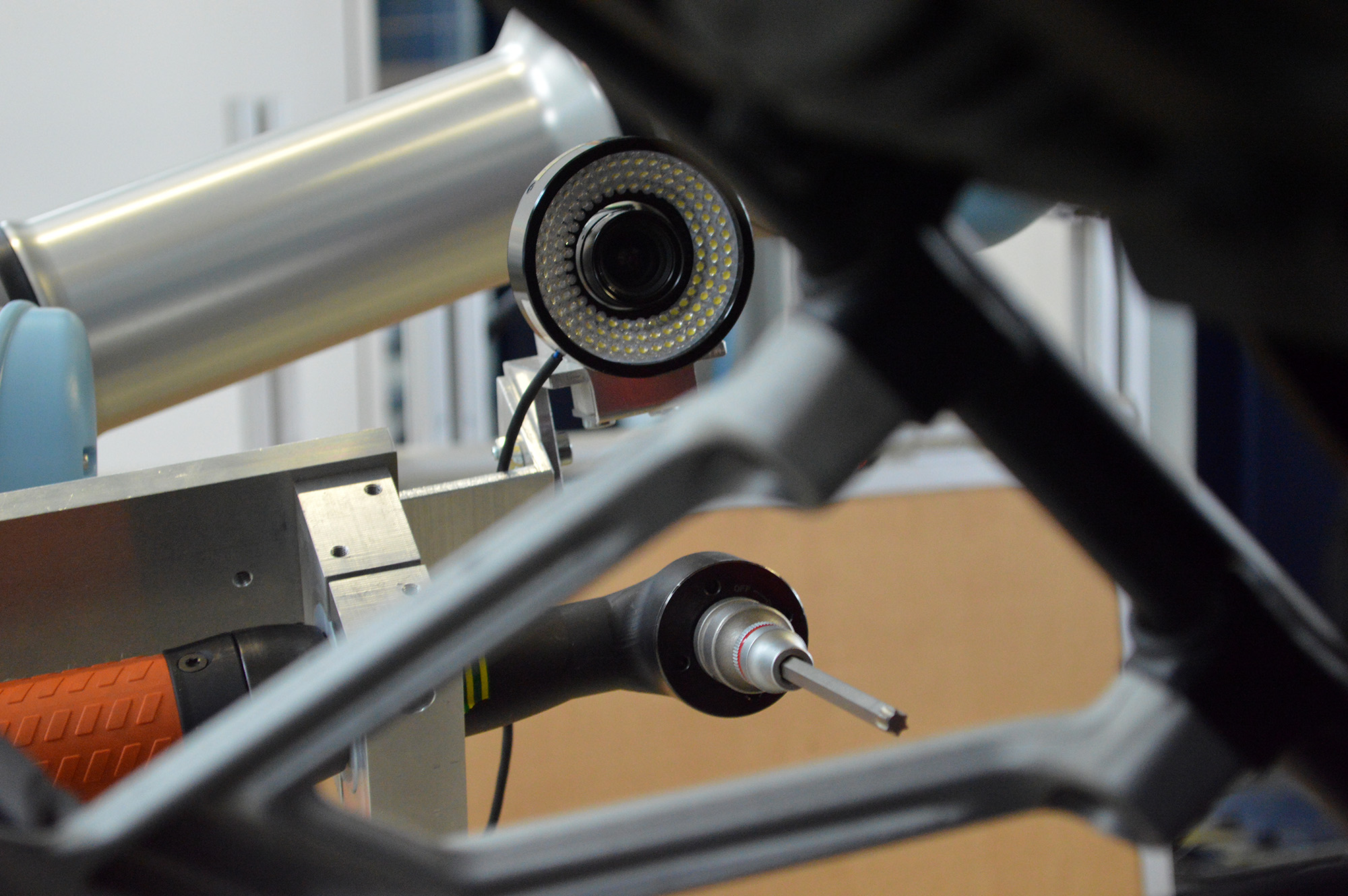

Optimization potential in production and manufacturing thanks to automation

Together, we evaluate the most suitable technologies in workshops. This involves identifying technical risks that may be relevant to developing the automation solution. The results of the analysis are summarized in a report.

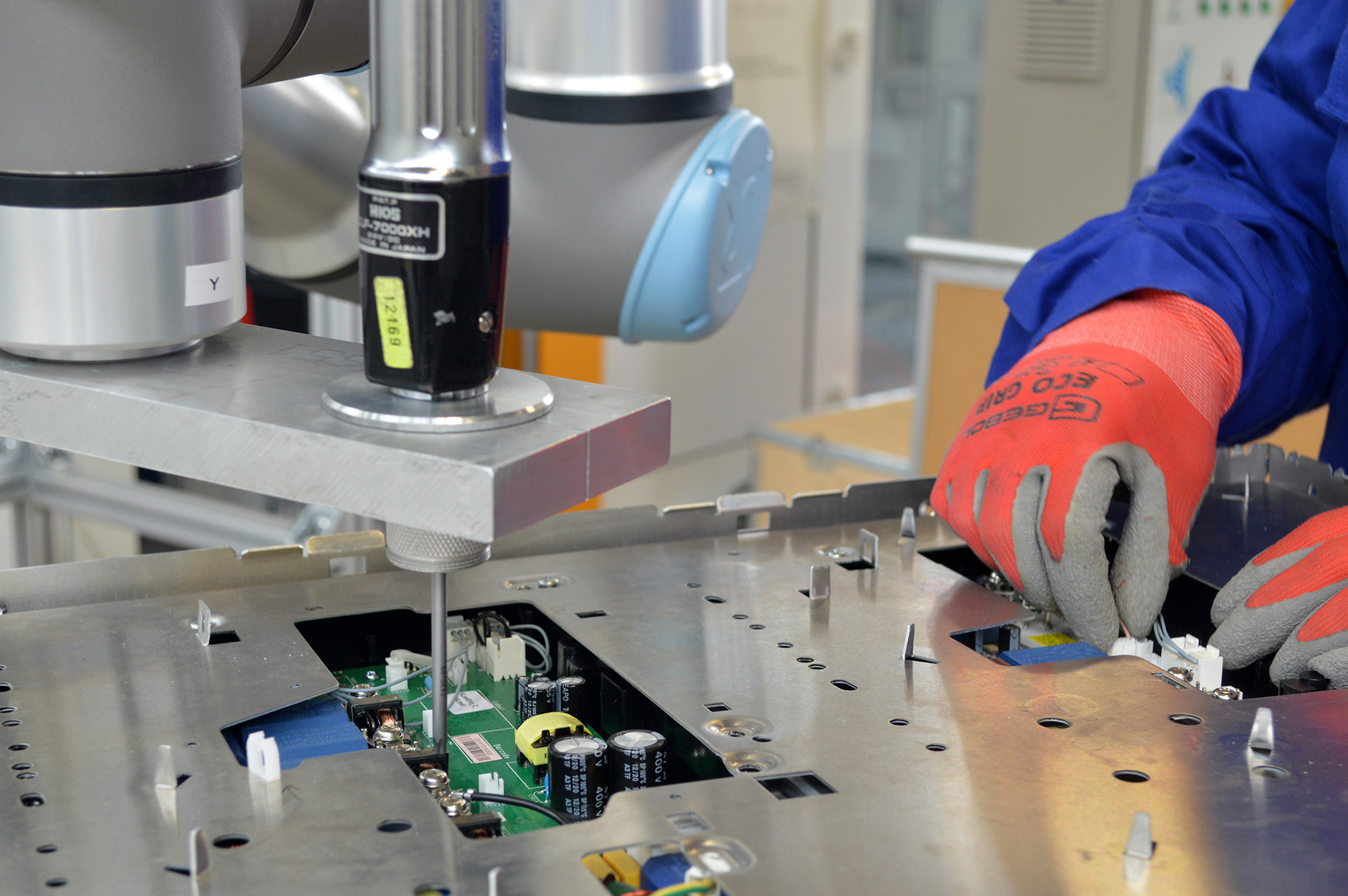

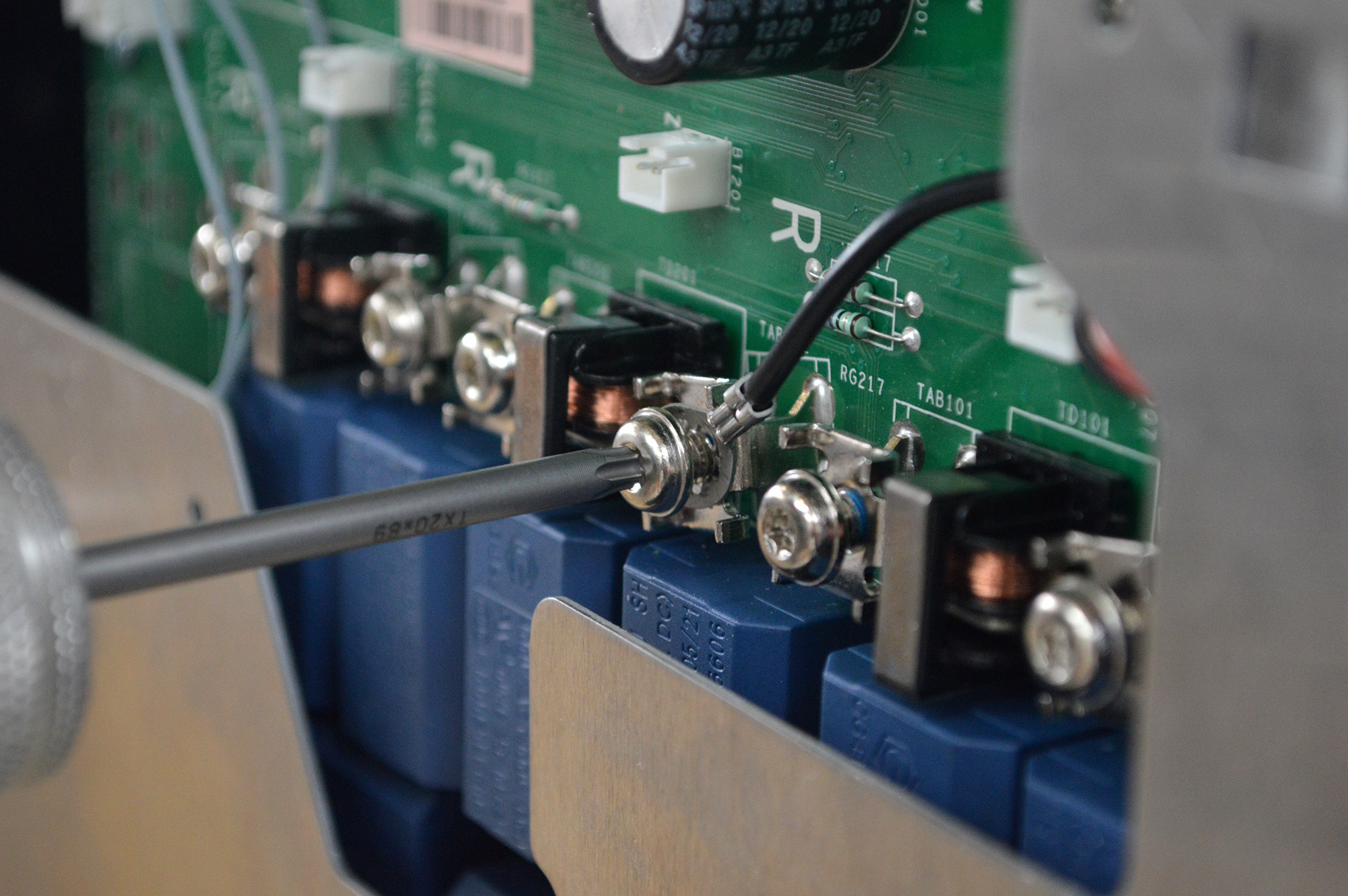

The automation assessment ends with a presentation of the results to the customer, during which our experts present a customized solution for your company. They will answer questions such as: What does the path to full automation look like? How does the human-robot collaboration work?

We are also happy to support and advise you beyond the initial concept phase. Consult with our experts and benefit now!

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology