Optical AI testing – your products for a free potential analysis

AI technology with minimal integration effort

Technology information

Important: The project "VIADUCT" is a public project funded by the German Federal Ministry of Education and Research. In order to implement the potential analysis, we create images of your products, which will be transferred to a publicly accessible data set after project completion. If you do not want images of your products to be published, please contact us to discuss potential cooperation outside the framework of the project.

What we need

- Objects that are well defined in length, width and height

- At least 10 defect-free objects per product

- At least 10 objects with production defects per product

- Longest embossment should be at least 5 mm and maximum 500 mm.

- Surfaces must not be reflective

To ensure functional and aesthetic properties of a product, Fraunhofer IPK is developing novel approaches for data-reduced AI applications. Thus, it is possible to integrateThis facilitates integrating the advantage of AI-based image processing into the inspection process without having to accept the resulting large effort of training data collection. This is possible by reformulating the inspection task.

Purpose and advantages of “VIADUCT” research project

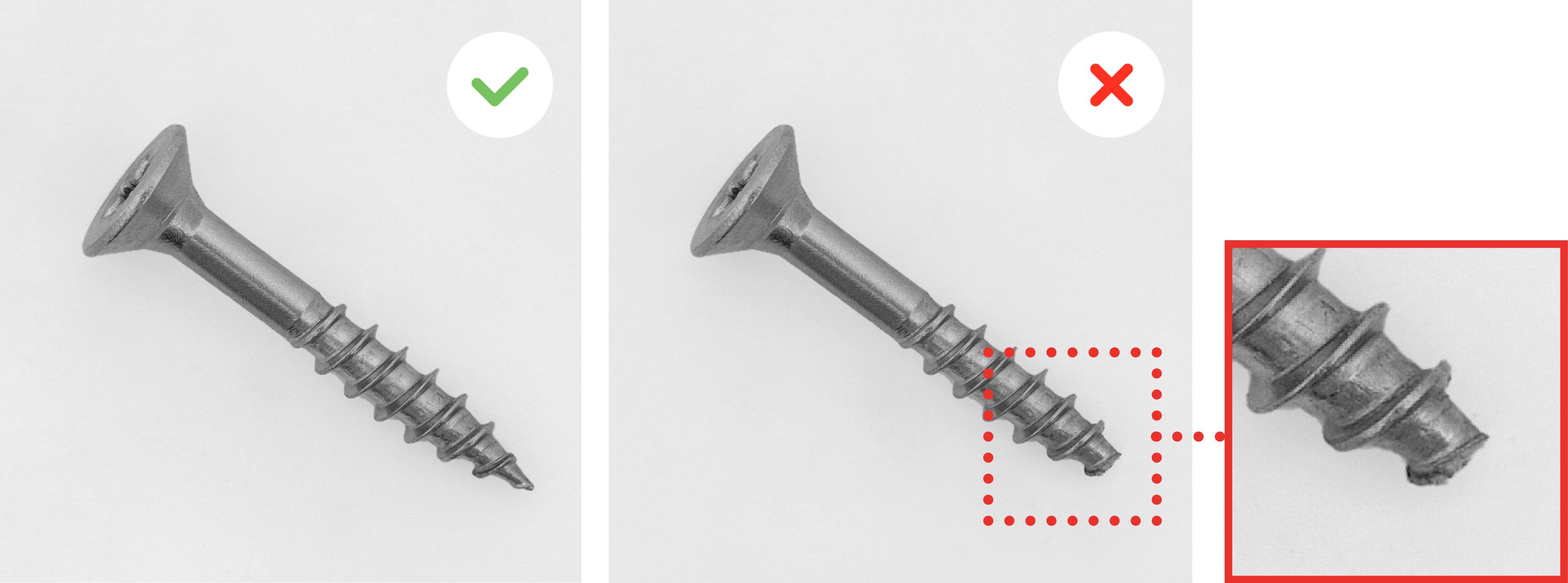

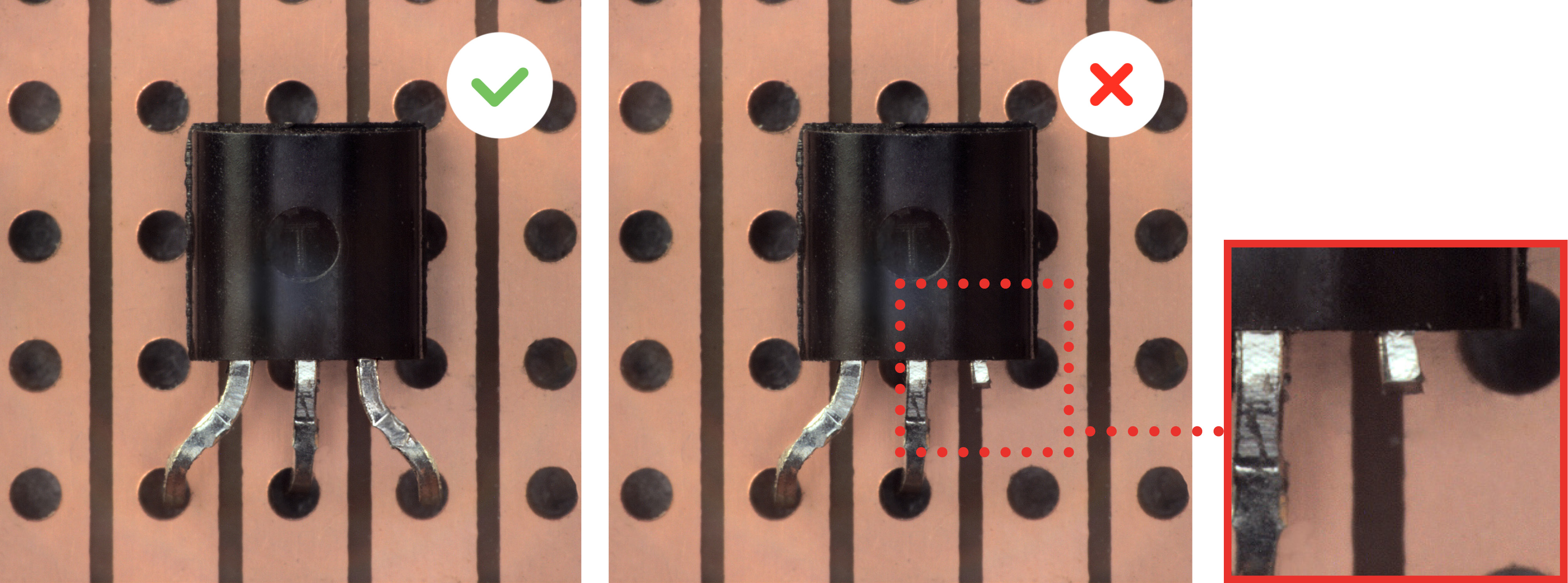

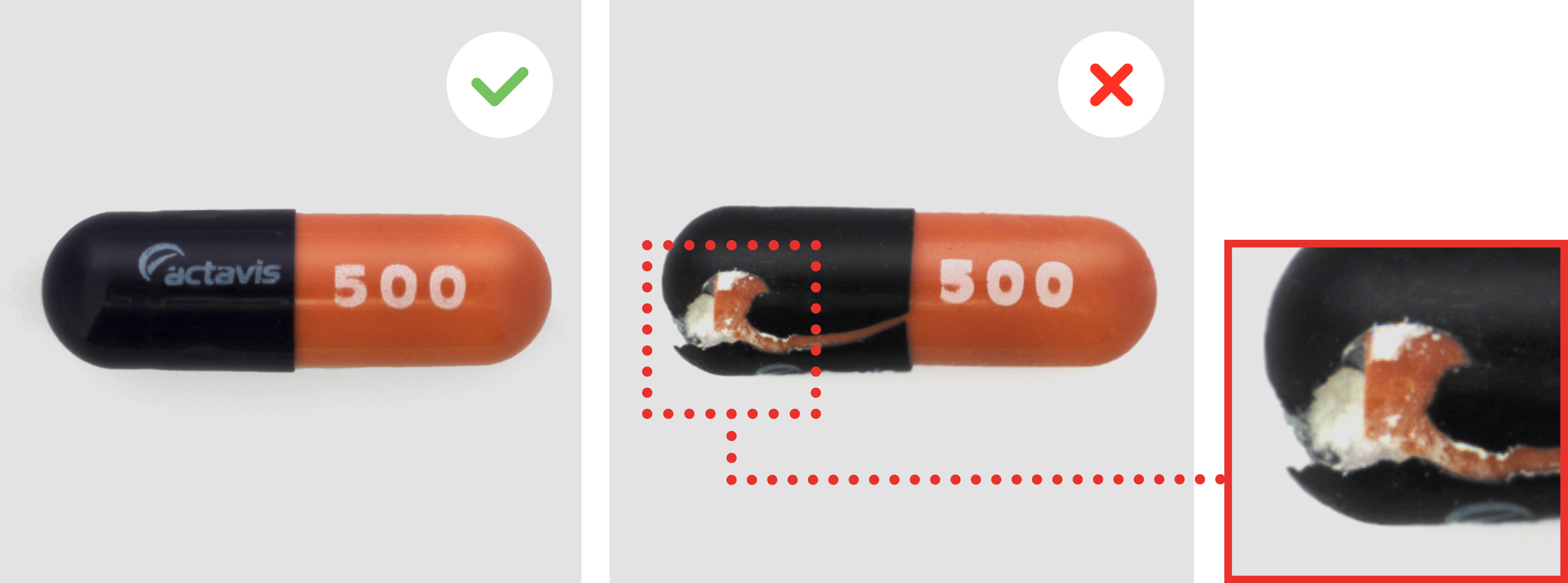

Instead of explicitly detecting learned defects in images, any deviation (anomaly) from a defined quality standard is detected. For this purpose, the AI is trained only with defect-free products, which naturally exist in significantly larger numbers than defective products.

This has two further advantages:

- Not all production-related defects have to be known in advance.

- The high personnel costs for data collection and manual marking of each individual defect are eliminated. The technology of image-based anomaly detection thus offers great potential to revolutionize the application of automated optical inspection.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology