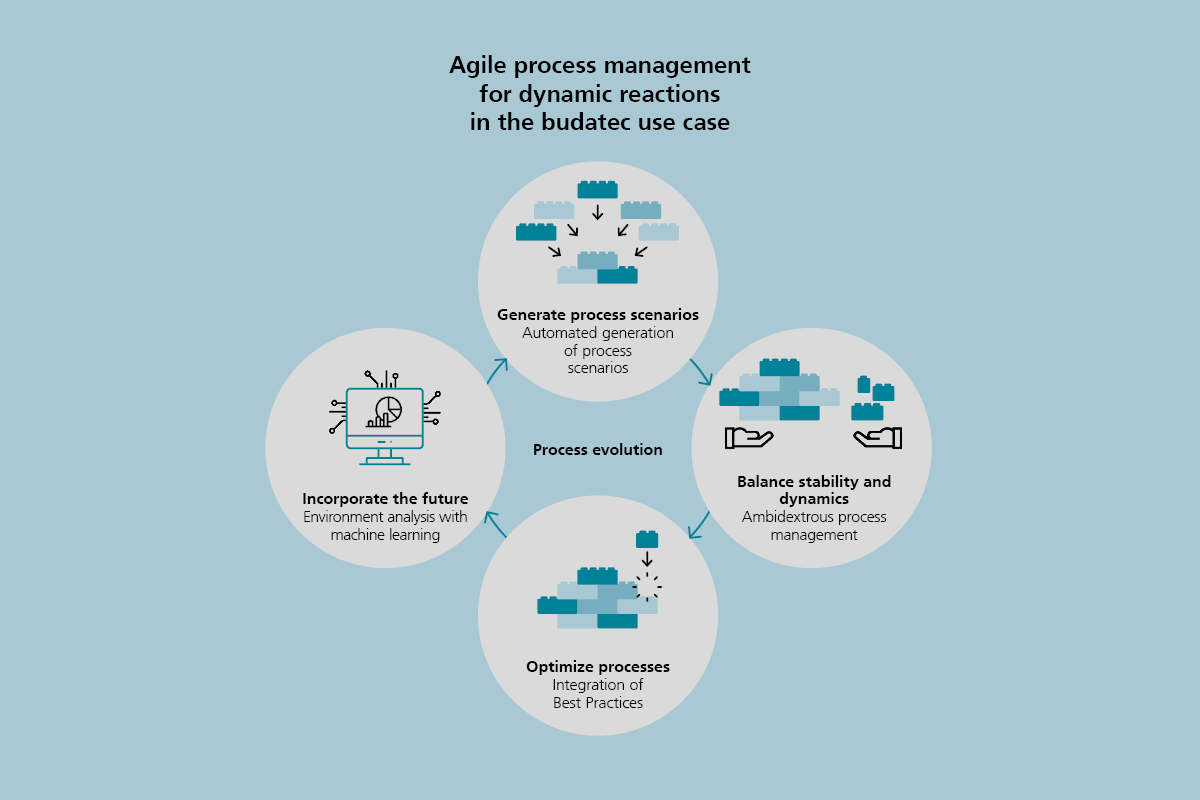

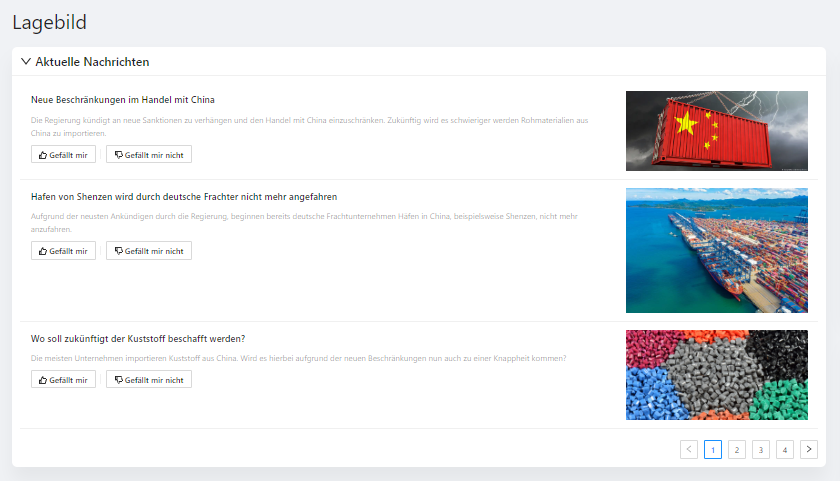

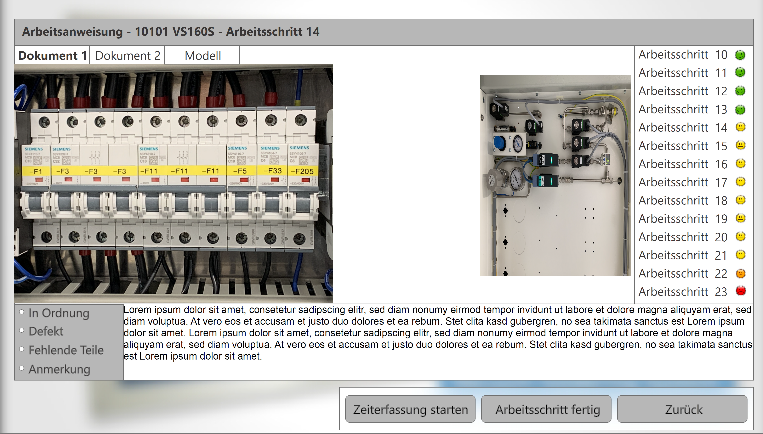

budatec GmbH is known for taking individual customer wishes into account. In addition to tailor-made machine solutions, standard machines are also adapted to fit customer-specific needs. This means that no two machines are alike. In order to support employees on the shop floor, an assistance system was developed that displays the respective work steps and also allows documentation. An AI-based environmental analysis was also developed to help the company identify changes at an early stage, visually displayed in the interactive situation report. The resulting time advantage allows the company to prepare for changes proactively.

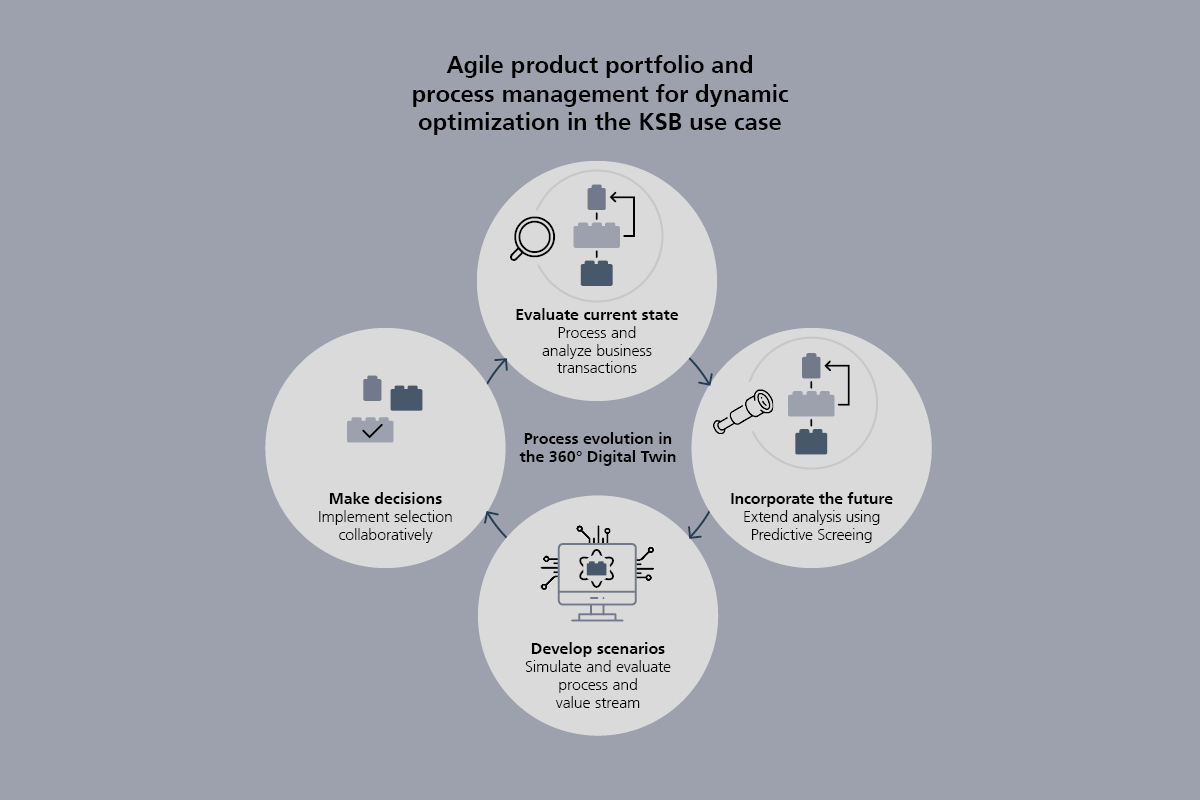

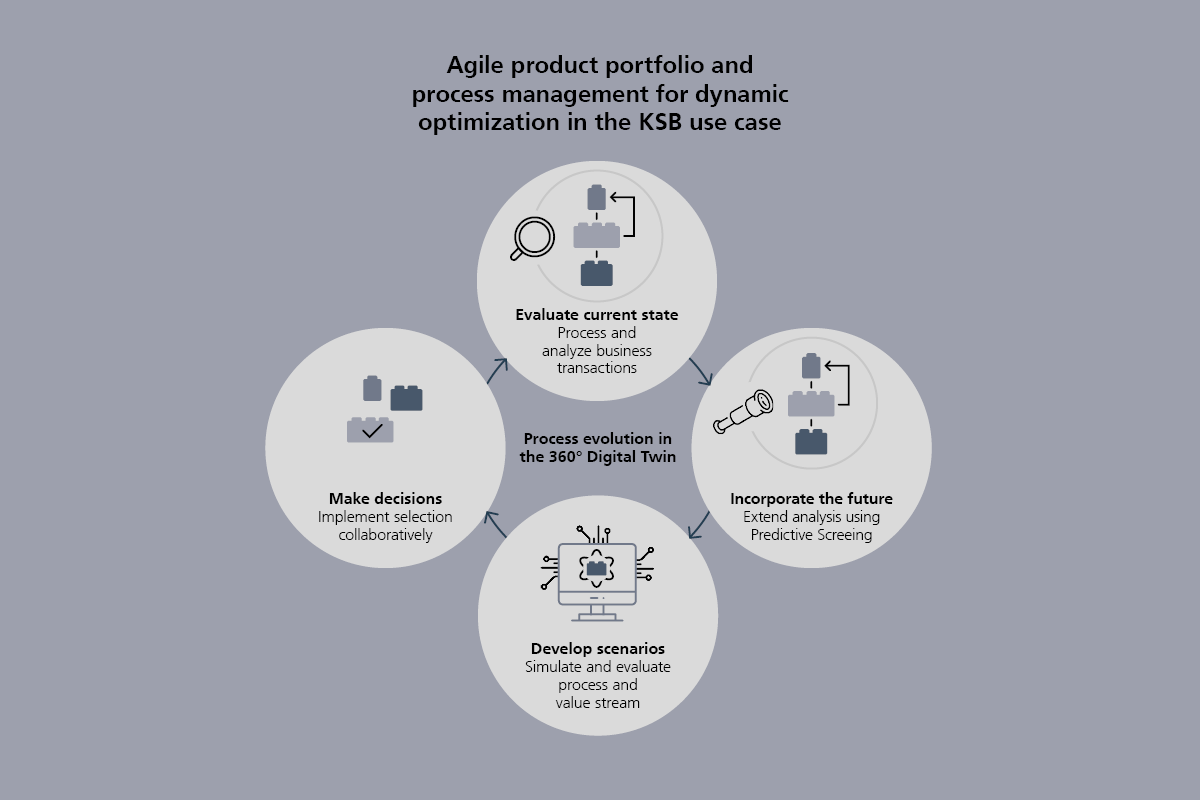

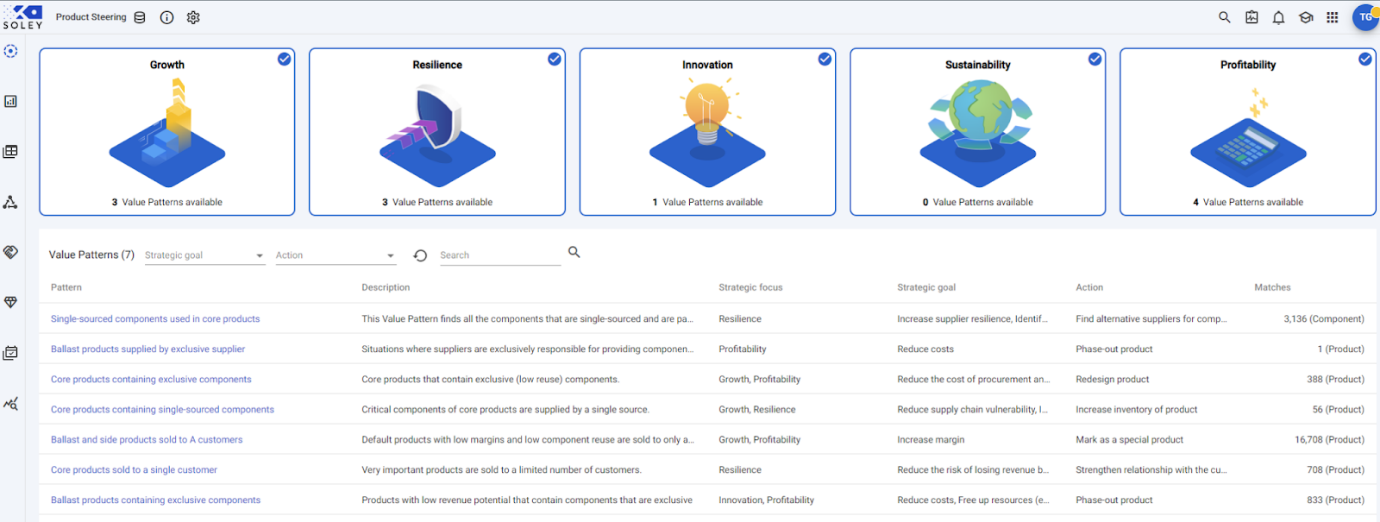

KSB SE & Co. KGaA is known for its numerous pump variants. Changing legal regulations can influence the profitability of the individual variants. The strategic foresight method is used to identify these changes at an early stage with a tool that is already commercially available for this purpose. To make this tool easier to use, an interface was developed for the automated entry of search terms, which makes it easier to build the search string. A profitability analysis is also essential to make decisions regarding the product portfolio. To support this, product mining using the “Soley Impact Manager” was used and further developed in the MAP project.

The project was accompanied by Chinese-German collaboration. Within this partnership, barriers that inhibit collaboration and measures to avoid them were identified. In essence, it was shown that while similar barriers generally exist in international collaboration, only their severity differs from country to country and from team to team. These barriers can be attributed to both cultural differences as well as personal experiences.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology