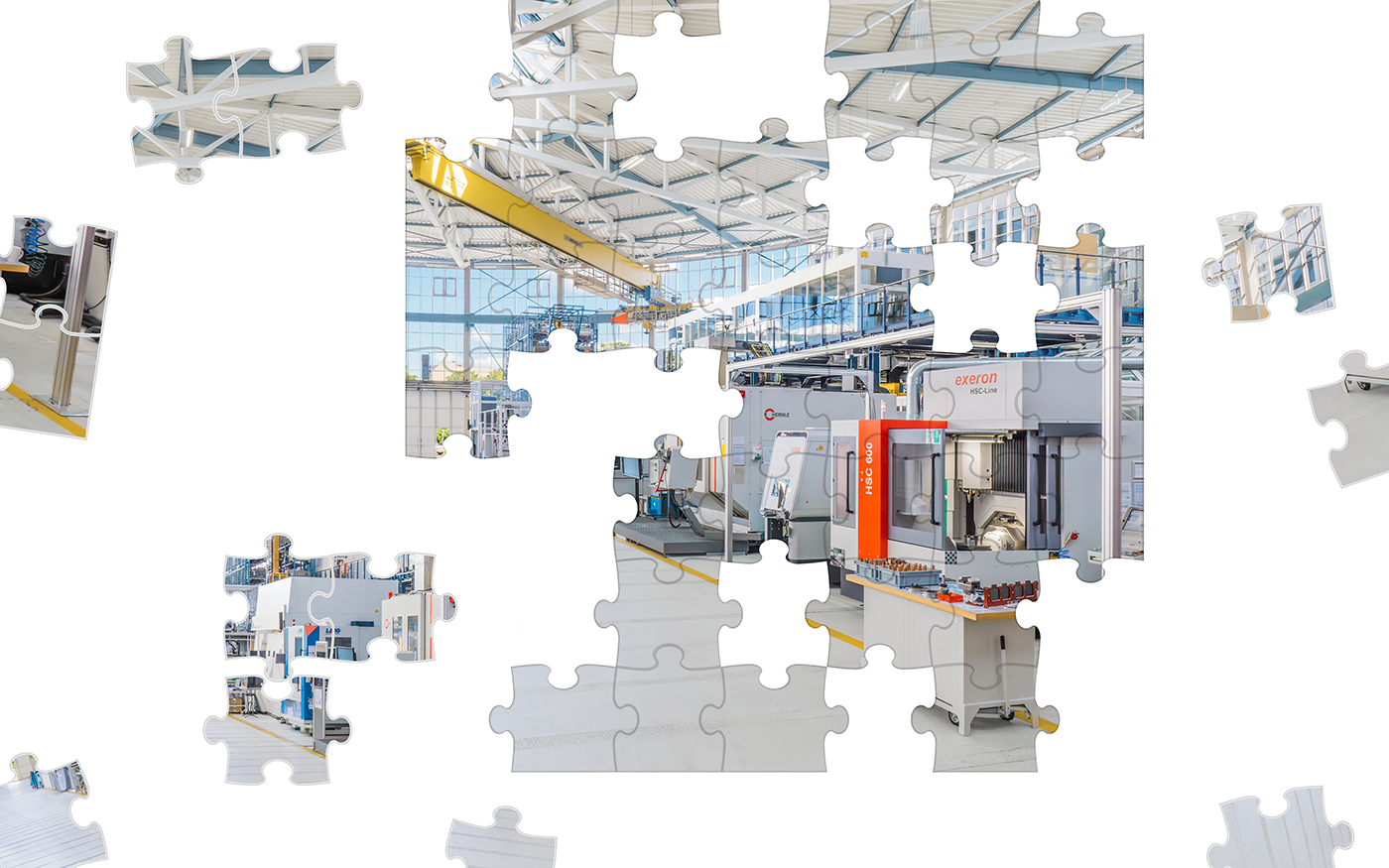

The development of system integration in industry is closely linked to technological advances and changing paradigms in production. System integration has evolved from describing the mechanical, rigidly coupled organization of production processes to an increasingly networked and automated structure.

In the second industrial revolution, shaped by Taylor and Ford, the division of labor was systematically realized in production lines. This phase of system integration was primarily mechanical in nature: Machines and workstations were rigidly linked together in order to achieve high efficiency in standardized production processes. When information technology and automation made further advances in the third industrial revolution in the 1970s, the idea of system integration changed. A new vision of Computer Integrated Manufacturing (CIM) represented a major step forward: For the first time, different systems within a company were designed to communicate with each other, significantly improving the planning, control and execution of production processes. Nevertheless, flexibility remained limited here too, as this type of system integration was still based on predefined, often rigid structures.

In today’s era of Industry 4.0, Cyber-Physical Systems (CPS), the Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) are driving integration by enabling deep connections between physical and digital systems. These technologies strive for a completely flexible, self-organizing production in which machines, products and IT systems communicate with each other in real time and can adapt dynamically to changing conditions.

However, mechanical and digital integration is still often limited in its flexibility and, if present at all, restricted to individual ecosystems. Many production systems continue to be rigidly structured, which makes it difficult to respond to changes in the market or demand with agile production processes. Companies can only remain competitive through truly flexible, networked and adaptive system integration. This requires not only technological innovations, but also a new way of thinking in the design of production systems.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology