Jack of All Trades With a Tablet

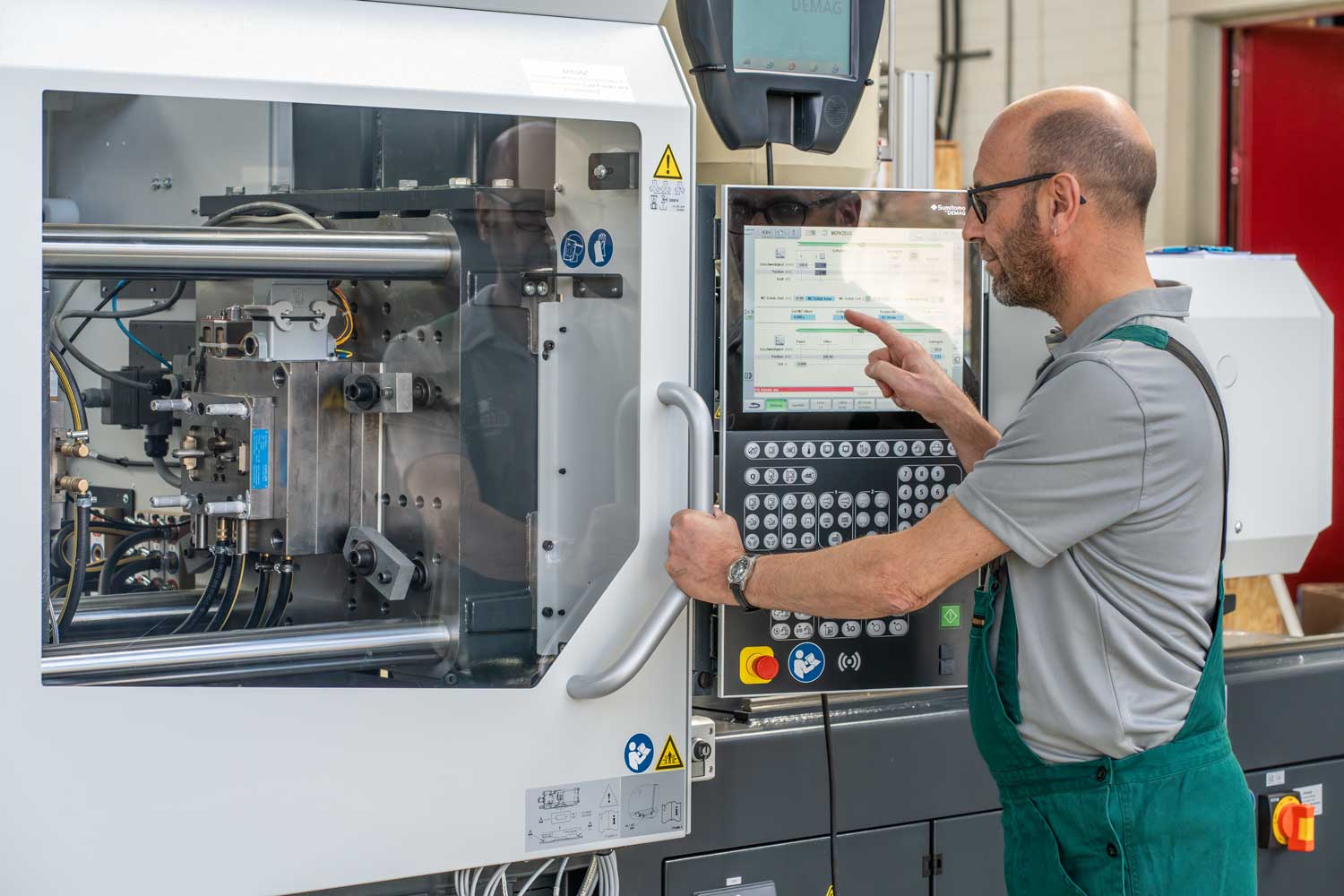

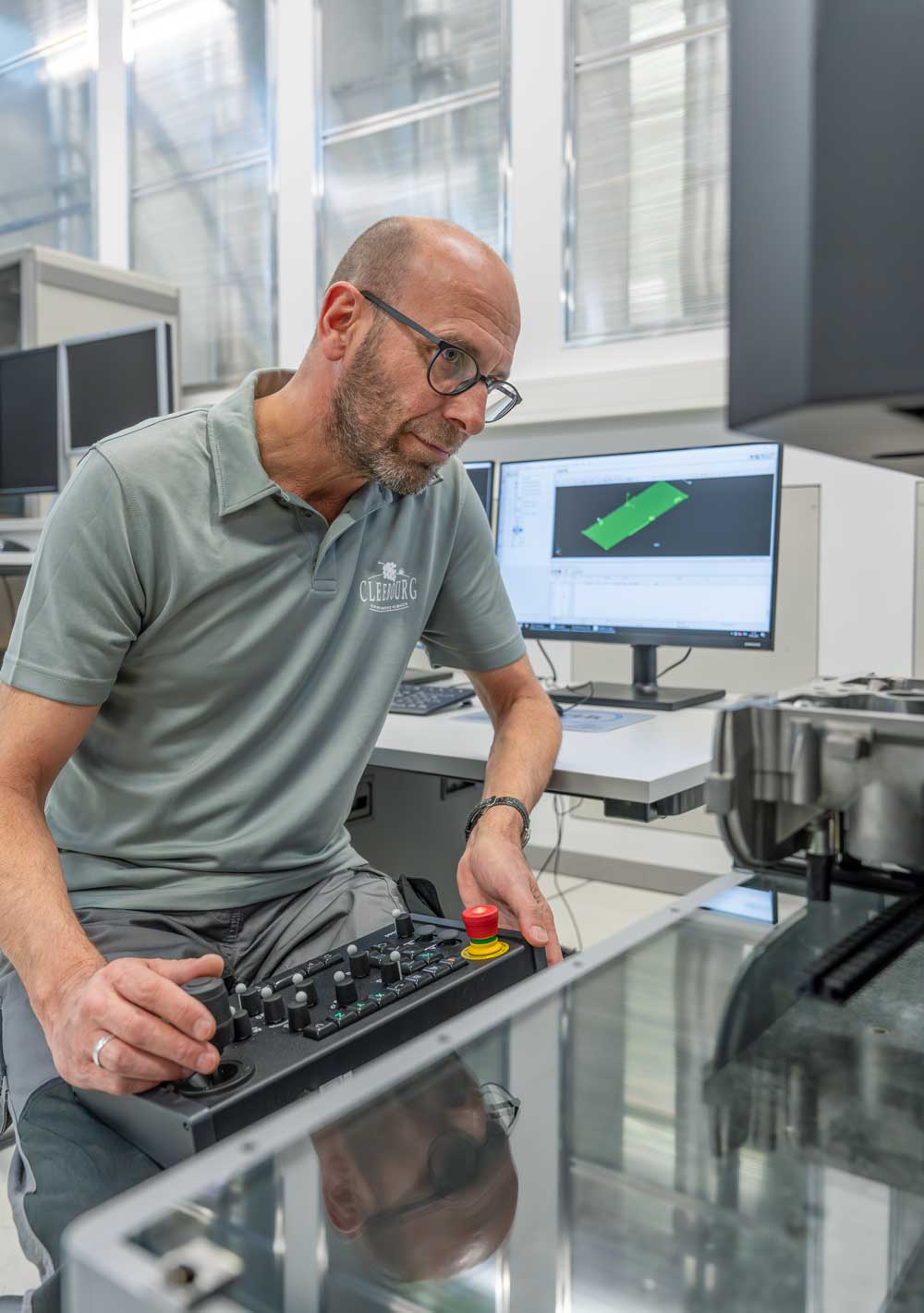

Imagine the following scenario: We find ourselves in the not-too-distant future. An automotive supplier is experiencing yet another staffing bottleneck, their fuel cell production is in urgent need of skilled workers. In order to fulfill their orders and not bring production to a standstill, they resort to the workforce of a temporary employment agency. The worker standing in front of the machine tool the following day has never operated it before. He pulls out a tablet, launches the web-based assistance system and gets to work. Whether during set-up, starting the NC program or unloading the finished parts – the assistance system provides step-by-step guidance for all important processes. In the assistance system, extensive expert knowledge is presented so clearly that the worker can take on complex tasks that would otherwise only be possible with years of practice and expertise. This applies to the most diverse areas: One month later, the same worker is already operating the injection molding machine of a medical equipment manufacturer, soon thereafter he is carrying out high-precision optical measurements of valve bores on camshaft housings. Sounds too good to be true? Maybe not for much longer!

Coping with complexity

One of the fundamental challenges in view of the shortage of skilled professionals in production and maintenance is the short-term integration of people with different levels of qualification, especially in increasingly complex production facilities that include mechanical as well as electronic and digital elements. Language barriers, which can hinder smooth communication and collaboration, further complicate matters.

Researchers at Fraunhofer IPK are therefore developing assistance systems based on simple mobile devices. The aim is to provide situation-specific information in order to minimize the effort required for finding information or general coordination, including documentation. »Situation-specific« here refers to both the technical context, i.e. which task is to be completed using which tools, and the level of qualification of the employees.

Such an assistance system can help workers who are brought in during temporary staff shortages to reduce errors and minimize stress caused by uncertainty. A validation process continuously running in the background also gives workers the confidence that they are not on their own. Finally, this approach enables on-the-job training and the creation of a knowledge database by linking the entered data and instructions to the digital twin of the machine or system in question.

Assistance in the automotive sector

As part of the ReTraNetz-BB project, researchers at Fraunhofer IPK are working on a general solution that is going to be field-tested by original equipment manufacturers (OEMs) in the automotive sector. Their production lines are generally highly automated, but they still involve manual activities such as assembly tasks. The integration of workers often presents a challenge here – be it due to a lack of expertise from career changers or because of language barriers. Assistance systems enable a simpler and, in many cases, even language-independent access to knowledge and guidance and thus a more flexible allocation of workers.

The researchers’ overarching goal is to create an assistance and knowledge management solution specifically for the automotive industry: This should enable workers from different companies to carry out a variety of tasks at different workstations. This is particularly relevant in view of the impending loss of knowledge due to

retirement. Of course, no assistance system in the world can replace well-trained specialists, whose expertise and experience will always be indispensable. However, the assistance system’s database can at least make the valuable know-how of previous generations easier to process and pass on to less experienced colleagues.

The overall goal of the researchers is to create an assistance and knowledge management solution specifically for the automotive industry: This should enable workers from different companies to perform a wide range of tasks at different workstations. This is particularly important in view of the impending loss of knowledge due to retirements. Of course, no assistance system in the world can replace highly trained specialists, whose expertise and experience will always be indispensable. However, the valuable experience of previous generations can at least be more easily processed and transferred to less experienced colleagues in the assistance system's database.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology