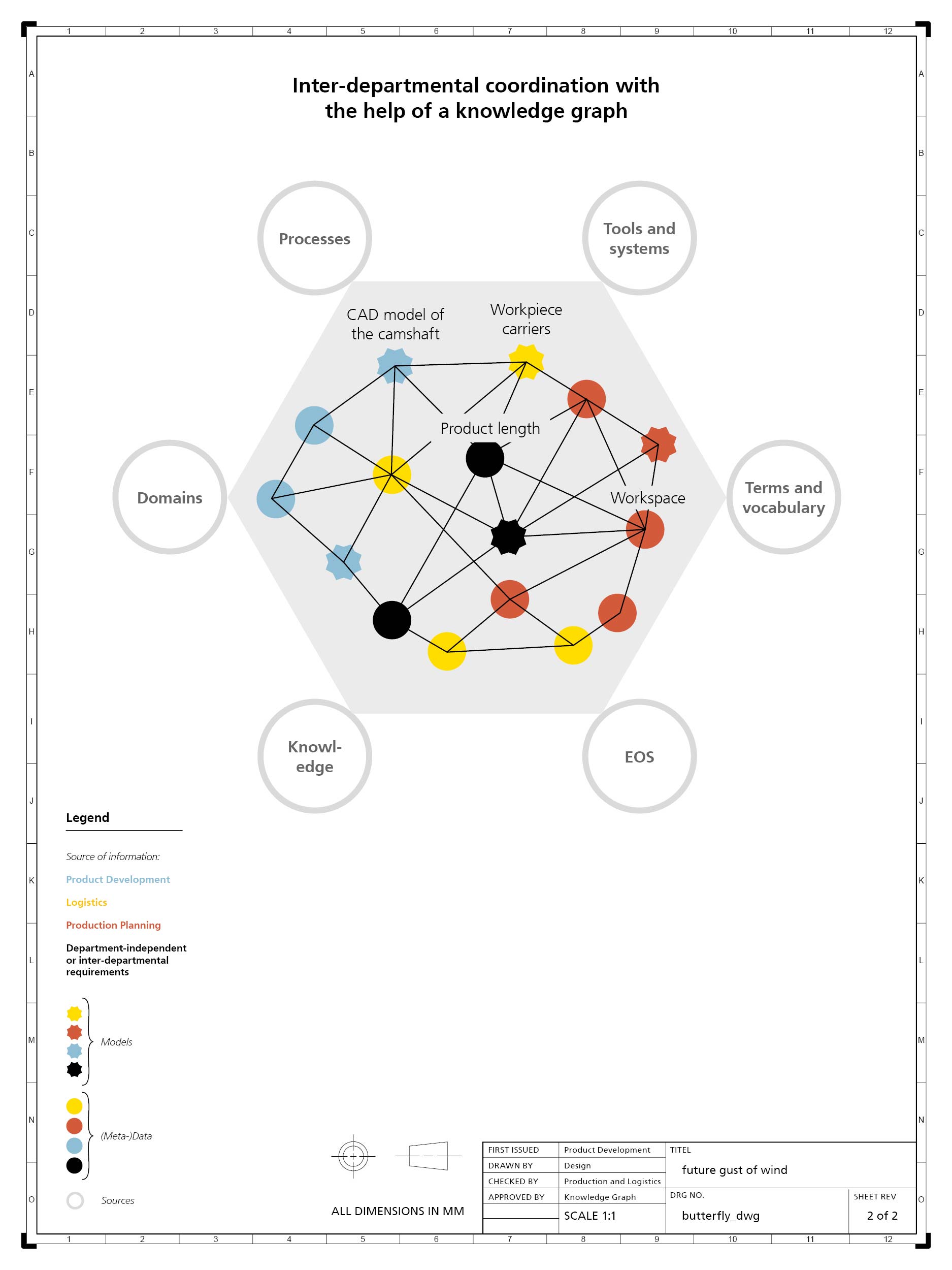

Small decisions in product development often have unpredictable consequences. Knowledge graphs help to make complex relationships more transparent.

An automotive supplier commissions the development of a new camshaft for a newly optimized engine type. The camshaft is five millimeters longer than the previous generation, meets all product requirements and fits into the engine after testing. Material costs – a few euros. In an ideal world, this is how development could work. Unfortunately, however, our world is much more complex than this idealized scenario. The developers did not realize what the five millimeters difference in length would mean for other areas of the company. In logistics, fewer shafts can now be transported on each trip, and the existing workpiece carriers no longer fit, either. A new logistics concept is needed. The production department also runs into problems with the new generation. The previously used machine can no longer produce the shaft – the search for a replacement is launched. But will an expensive new machine fit into the budget for production planning?

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology