No Waste Today

Every year, 11 million tons of food end up in the trash in Germany: yogurts purchased in too much quantity left to spoil in the fridge, or perfectly edible fruits discarded in bulk by supermarkets because their expiration date has passed. The throwaway society is wasteful with resources in other product categories as well. Clothing that is still in good condition and barely worn is discarded because the next cheap fashion items are already on display. Industry also generates a lot of waste: packaging, metals, old appliances. Instead of being repaired, defective IT devices, among other things, often end up in containers – along with valuable raw materials like copper or cobalt.

Although the consequences of such thoughtless resource handling are well known, current production and consumption habits continue to follow the logic of a linear or disposable economy – production, consumption, and disposal or incineration. It’s important to note that extracting and processing naturally occurring resources account for 50 percent of greenhouse gas emissions and up to 90 percent of biodiversity loss and water stress. Departing from this approach holds the great potential to decouple economic growth from resource consumption and enable a sustainable future.

Circular Economy as an Opportunity

The so-called circular economy offers a way out. The idea is to organize products and business processes in loops. One of the sub-projects of the BioFusion 4.0 research project illustrates what this may look like in practice: An orthosis is produced as an assembly aid using 3D printing, which is biodegradable at the end of its lifecycle. What’s special about it: Old cooking fats are used as base material. Precious resources that would otherwise have ended up in landfills and incinerators are thus reintroduced into the value cycle. The circular economy offers a chance to rethink our economic practices and adopt a pioneering approach to business activity that promotes the protection of climate, the environment, and biodiversity.

However, especially in small and medium- sized enterprises, financial, time, and, most importantly, personnel resources often leave no room for implementing circular economy principles not only on a technological level, but from a holistic, systemic perspective at business level. How can a company design its business model in a circular way?

Examining Business Models

At this point, Fraunhofer IPK provides support. A central part of BioFusion 4.0 is developing business models for the biological transformation – a conceptual framework across all sub-projects of BioFusion 4.0. This includes testing a general approach model and an action plan for the sustainable and circular transformation of existing business models.

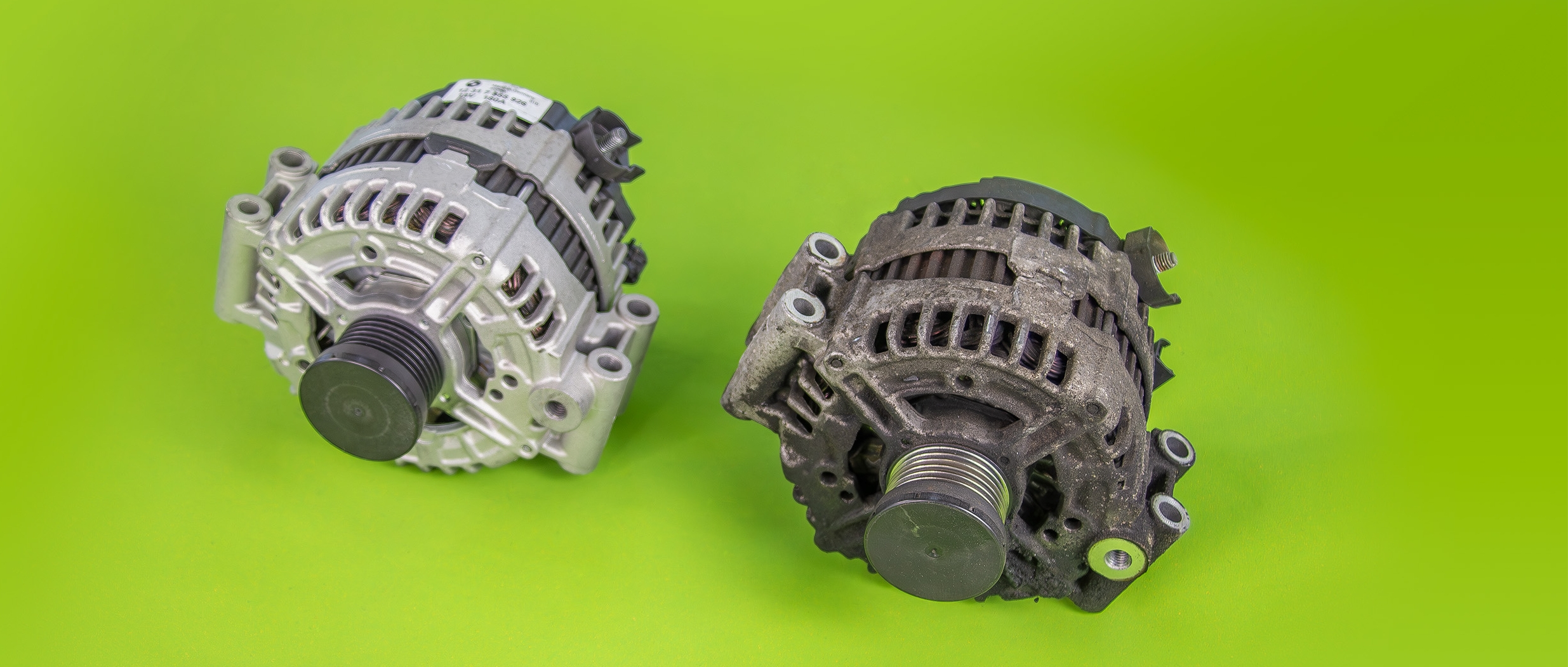

This approach model serves as the basis to identifying suitable circular business model patterns for strengthening the circular economy within the context of each individual company. Unlike the very specific business model of an individual company, business model patterns are general instruments that can be applied in any organization through clever adaptation. Examples would include take-back management or producing durable and repairable products. Business model patterns can thus be integrated into any specific business model of a company.

At the outset of a guidance process, the current business model is analyzed together: What is the value proposition – a physical product or a service? What does the company need for it – which resources, activities, partners, and suppliers? Who is the offer aimed at – what customer segments, customer relationships, or competitors exist? What revenue sources are there? What does the cost structure look like?

In a second step, the potential for circular development of the business model is explored through specific questions. For example, in manufacturing, effective take-back management can save on material costs and reduce dependencies on high commodity prices in global markets. These potentials form the basis for the final selection of measures to strengthen circular economy in the participating company.

Thinking Systemically About Circularity

A business model pattern catalog developed by experts at Fraunhofer IPK serves as a tool for expanding the circular economy in companies. The catalog is a collection of proven business model patterns and instruments for analyzing and designing the business model based on the following circular principles:

- Rethink

- Reduce

- Reuse

- Repair

- Refurbish

- Remanufacture

- Repurpose

- Recycle

- Recover

Using these so-called R-strategies, suitable circular business model patterns from the catalog are selected in the last step of the guidance process and implemented in a specific value chain of the production process: For example, repairability must be considered at the beginning of the design process.

The pattern catalog helps companies become more circular, making a valuable contribution to Germany’s efforts to transform the domestic economy into a circular economy and make the transition to sustainable products and services. Thanks to Fraunhofer IPK’s methodology, even small and medium-sized enterprises have the opportunity to shape this transformation at business model level – and ultimately operate more resource-efficiently.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology