Mixing rethought

Technical mixing operations such as crystallization or precipitation reactions are part of many production processes in the pharmaceutical, chemical and biotech industries. The quality of the mixture not only determines the quality of products such as active medical ingredients and nanoparticles, but ultimately also their effectiveness. The Fraunhofer Dynamic Mixing Technologies achieve mixtures of unprecedented homogeneity with minimal mixing times and are scalable over a large volume flow range, enabling efficient and robust series production of pharmaceuticals and chemical industry products, for example.

Production of nanoparticles to encapsulate active ingredients

One application example is the production of nanoparticles, such as those used in mRNA vaccines. For these vaccines or other RNA-based drugs, the active ingredient is encapsulated in a protective coating so that it can be transported into the cells in the human body and released there.

For this purpose, the active ingredient dissolved in a buffer is mixed with another solution, e.g. a lipid or polymer solution. As soon as these two liquids are mixed together, nanoparticles are formed that encapsulate the active ingredient. The resulting particles are significantly smaller and more homogeneous, and the particle size can even be adjusted.

For laboratory use, so-called microfluidics are used, which produce a very good and fast mixing, but only allow a very low throughput. So-called impinging mixers (also known as T-mixers or Y-mixers) are available for industrial-scale applications. They enable a high throughput, but at the cost and expense of the mixing quality. This emphasizes the problem of scaling up laboratory processes to manufacture series products. The situation is very similar with nanoemulsions, in which a stable emulsion of otherwise immiscible substances, such as water and oil, is produced.

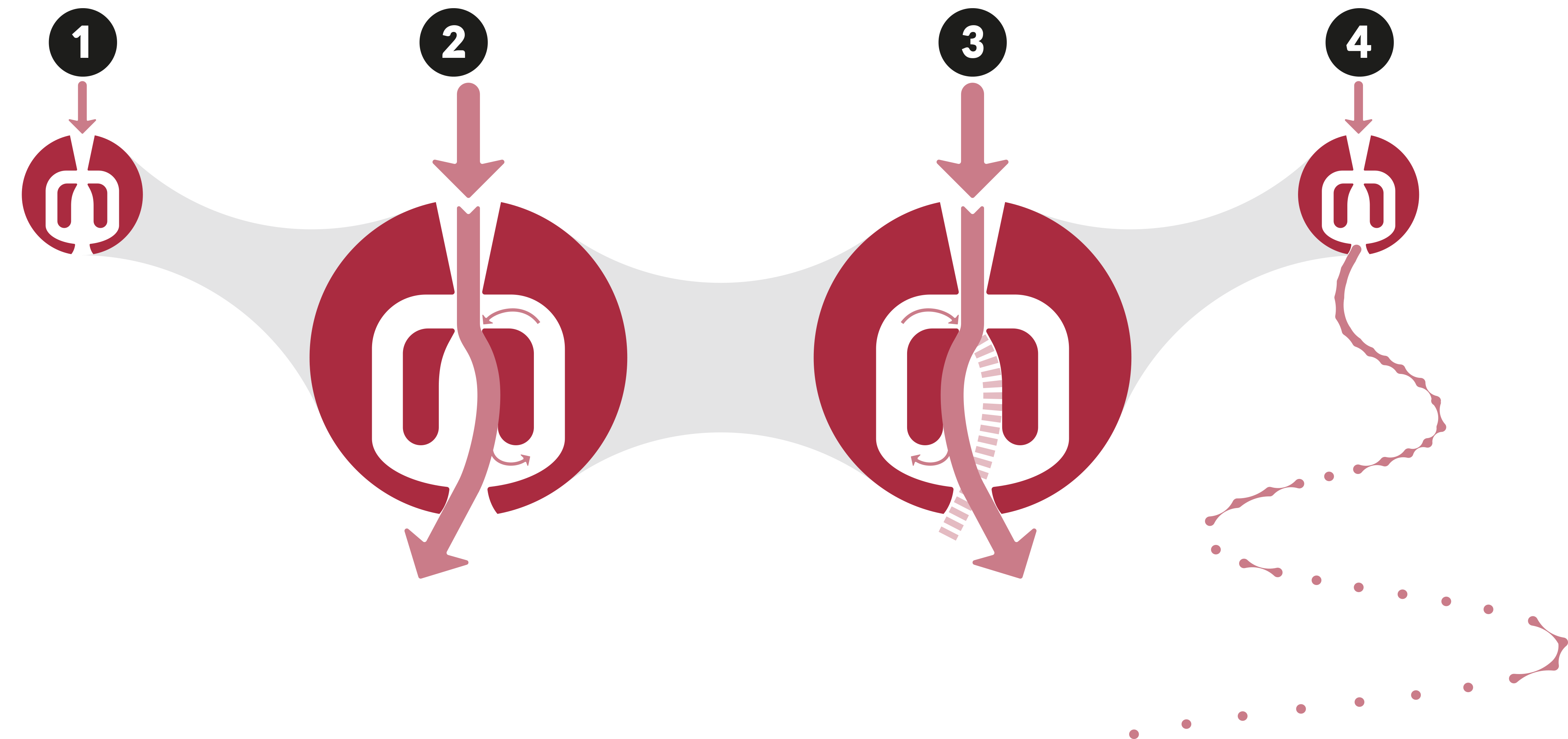

Fraunhofer IPK was able to bridge the gap between mixing quality and throughput as part of its research and development projects together with FDX Fluid Dynamix GmbH. The resulting Fraunhofer Dynamic Mixing Technologies (FDmiX) platform allows a consistent mixing quality and speed from laboratory use to series production and has already been successfully tested for the production of lipid and polymer nanoparticles as well as nanoemulsions. As the tests have shown, the mixing quality of the FDmiX platform is superior to many conventional systems.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology