Wire-based directed energy deposition for repair and reconditioning

Repair complex tools, molds, and components based on scan data

Scan-based repair using laser cladding is a modern technology used to recondition complex tools, casting molds, forged parts, and expensive individual components. It can be used to restore component geometry without the need for a CAD model. Thus, damaged components can be repaired using a fully digital process chain.

The welding system is equipped with an integrated scanner. This allows the component to be positioned in the system and digitized immediately. The scan data is then processed and the areas to be repaired are identified. The robot’s CAM paths are planned on the derived surfaces from the scan and finally transferred to the system. Welding can then begin immediately without any further changes.

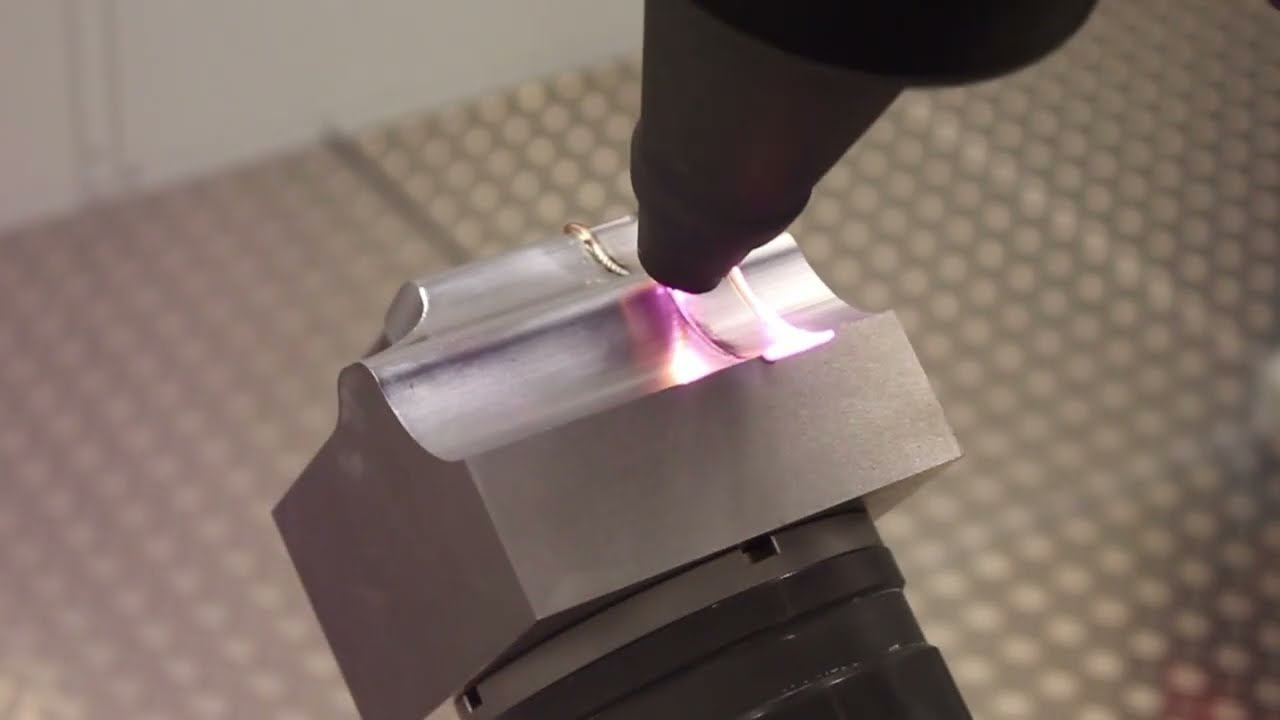

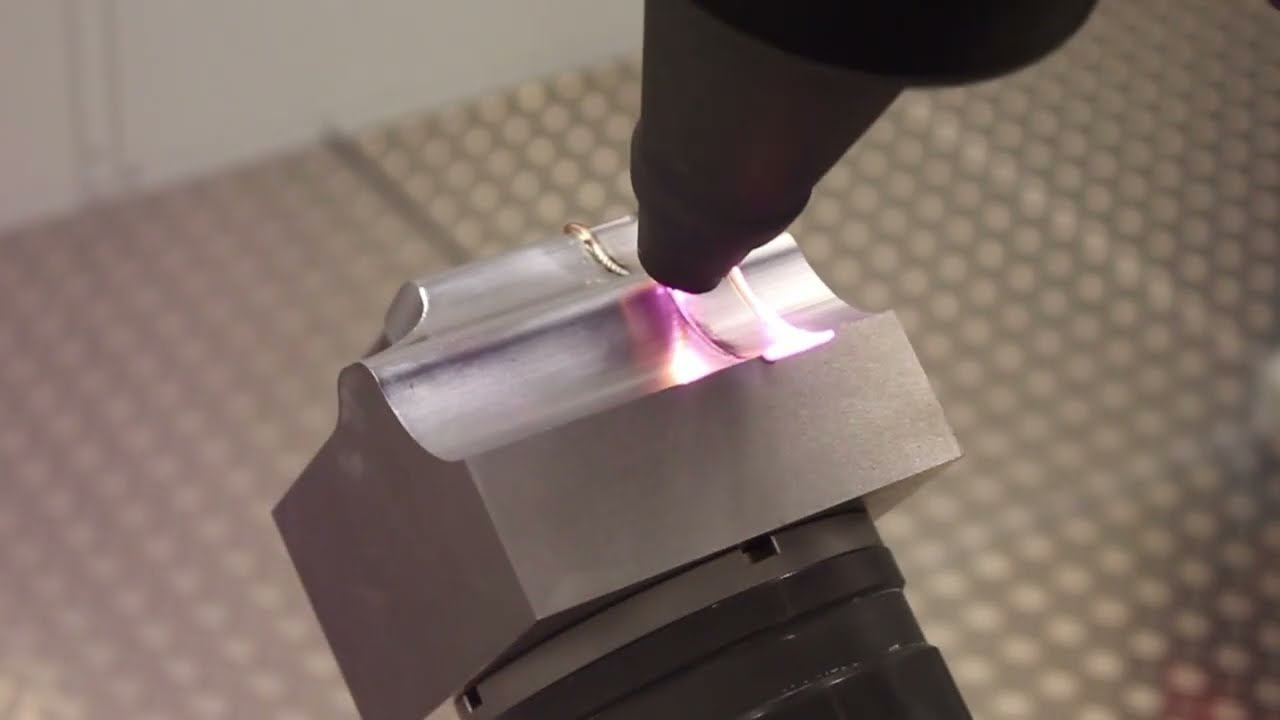

After preparation, the repair is carried out using wire-based laser cladding. Unlike powder-based laser cladding, wire is easy to handle and allows for a clean welding process. The hot wire option can additionally be used to preheat the wire, thus reducing the heat input into the base material. This enables the welding of difficult-to-process materials.

Innovative surface and volume reconditioning using laser wire DED.

Repairing complex tools, molds, and components is based on scan data and can be used for a variety of mechanical engineering and mold-making applications: