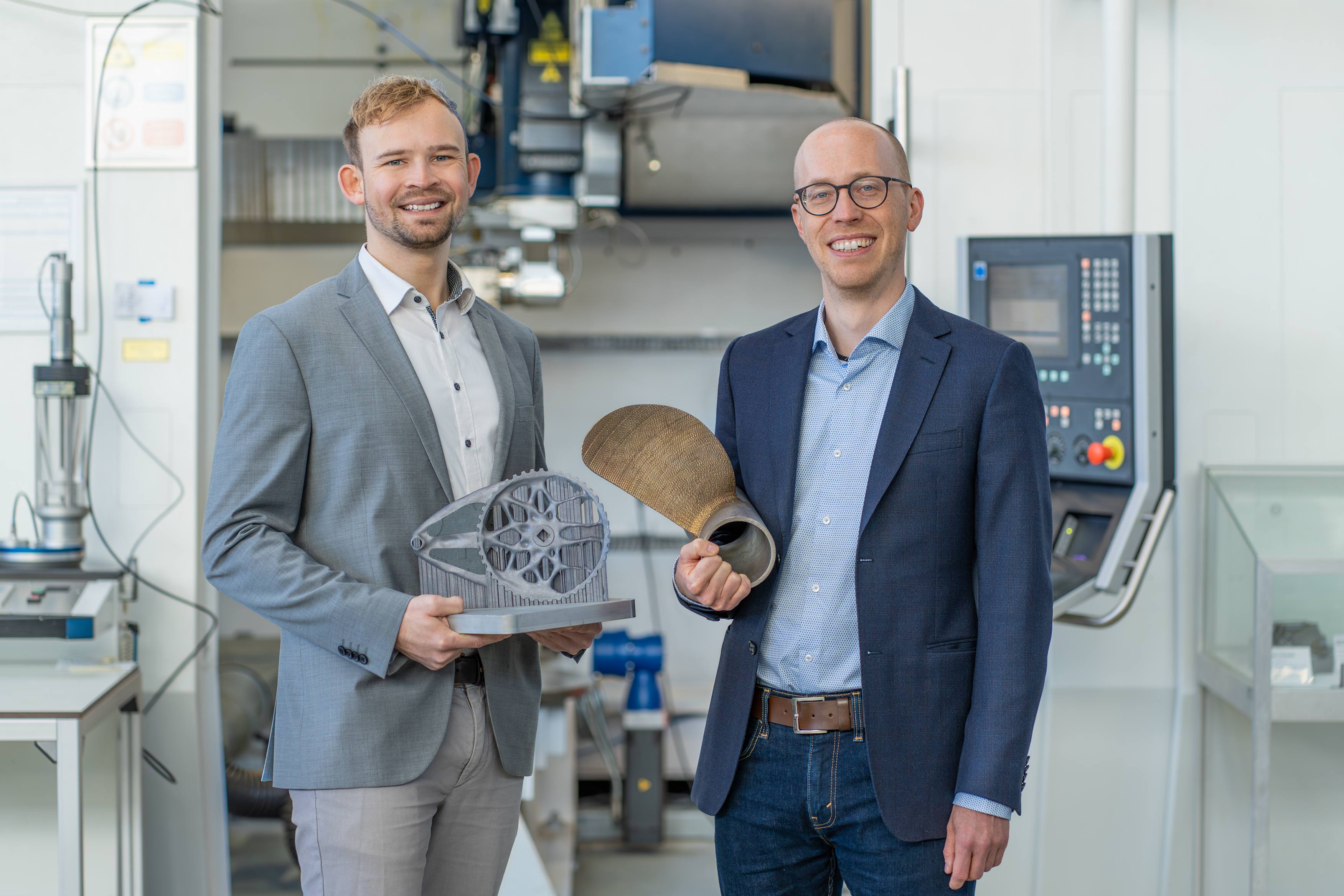

Tobias Neuwald, head of the Manufacturing Technologies department, and Dr. Max Biegler, head of the Joining and Coating Technology department, are experts in metal additive manufacturing.

What is the focus of your research right now?

Neuwald:

We are researching the use of powder bed technologies along the entire additive value chain. Here we investigate questions such as: Where are the limits when processing materials that are difficult to weld? What will the production systems of the future look like? What needs to be done to the components after printing? And how can I avoid having to do a 100 percent CT-inspection in safety-critical applications such as aviation, medical technology or the energy sector?

Biegler:

We stay close to the process: How do I apply certain materials? How do I design the process to robustly achieve high quality results? We mainly investigate these questions for DED processes. We also support companies in the selection of use cases: Where is using additive manufacturing technologies economical?

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology