Blockchain and Industry 4.0

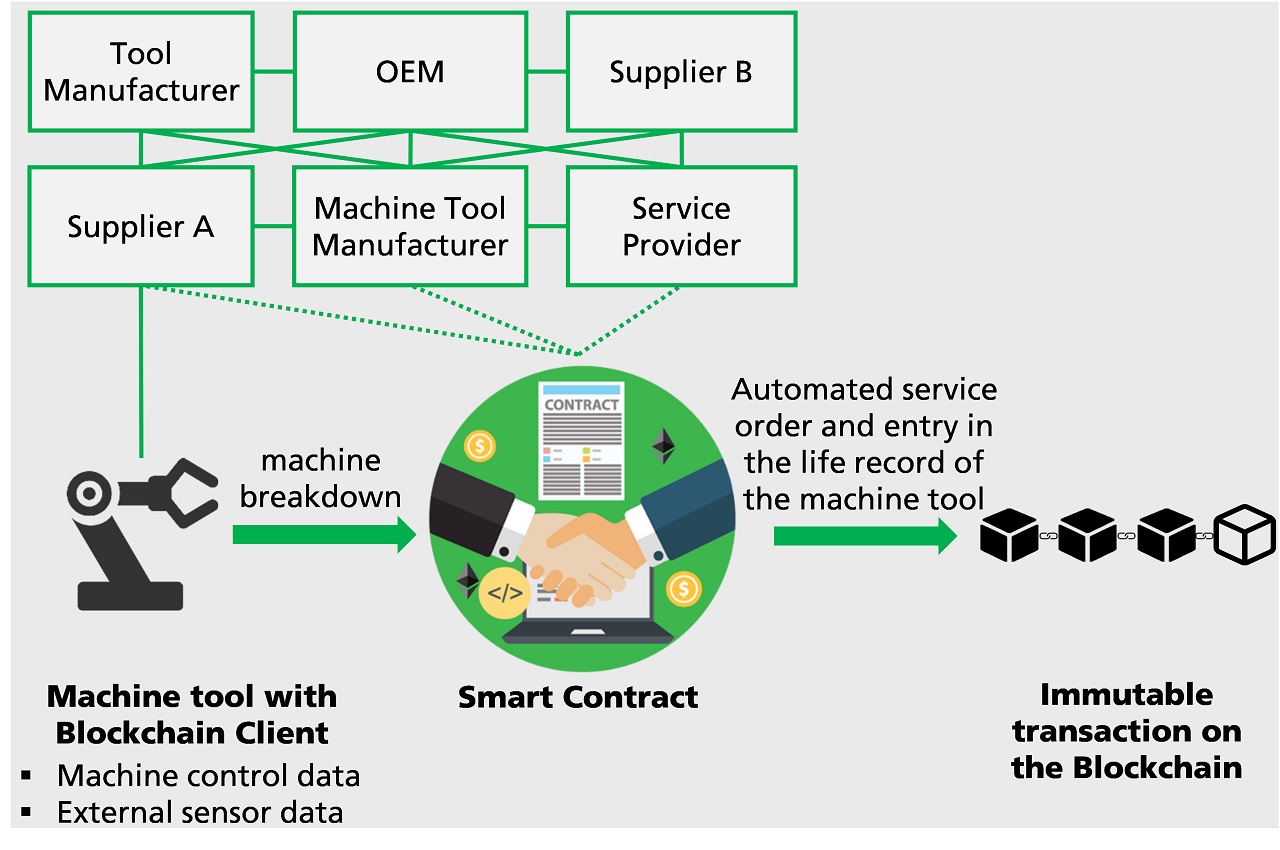

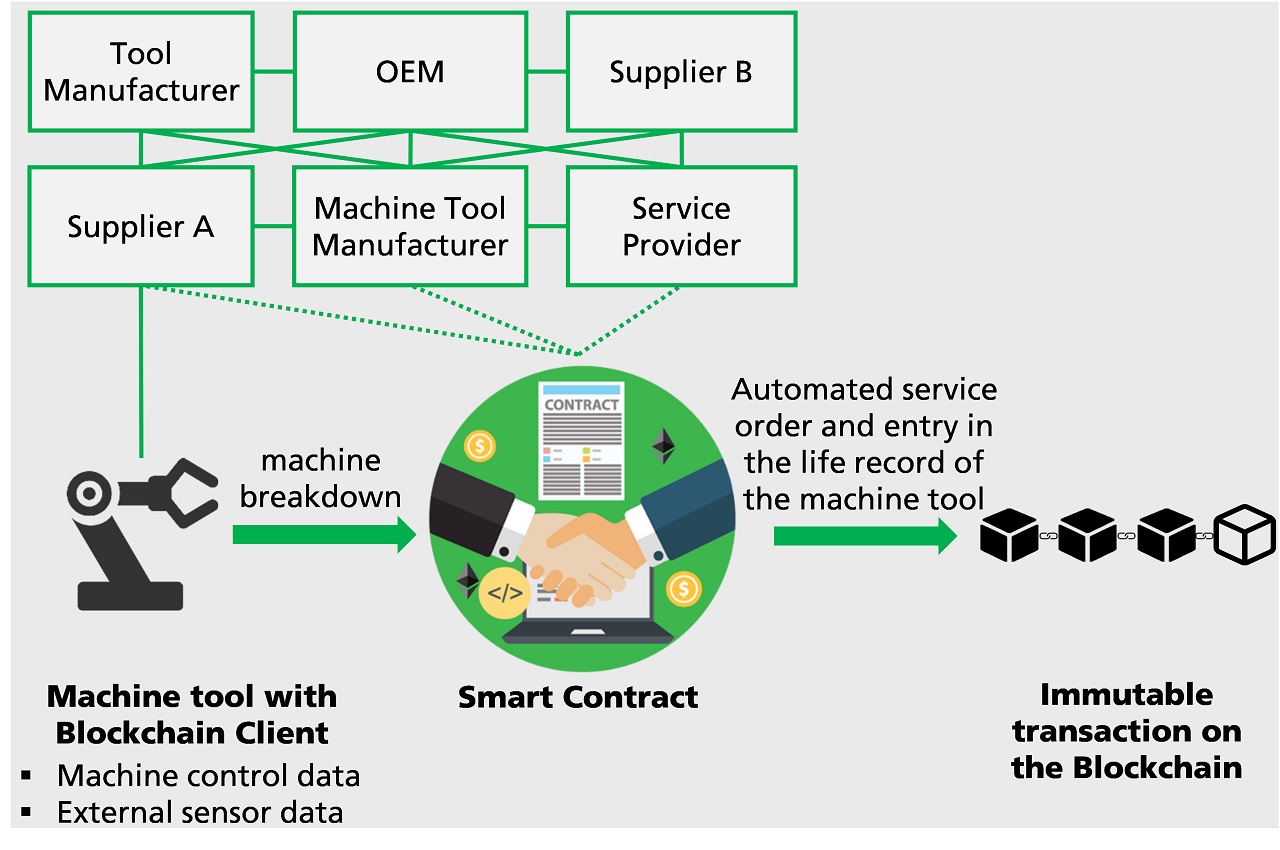

Blockchain-based manufacturing network

Industrial manufacturing processes generate large amounts of process and sensor data, a major part of which currently remains unused. An important reason for this squandered opportunity is that companies are understandably wary of making sensitive process data available for use via vulnerable web services. Distributed Ledger Technologies (DLT) such as blockchain offer the possibility to provide a basis of trust between parties with very different interests. Fraunhofer IPK researchers are exploring how these technologies can help enterprises in making better use of their data.

In cooperation with companies like Contact Software or Unibright, our scientists are researching different aspects of this complex and promising field, such as

- providing data security for additive manufacturing processes,

- developing a Hyperledger Fabric demonstrator and adapting it to the guidelines of the Baseline Protocol,

- expanding said demonstrator to include integration into SAP.

In May 2020, Fraunhofer IPK joined the Specifications Steering Committee (SSC) of the Baseline Protocol. Researchers are now collaborating with Unibright to explore the potential of the Baseline Protocol for the manufacturing industry. In follow-up projects, common standards for the use of Baseline in Industry 4.0 and IoT are to be developed together with manufacturing companies.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology