Connecting Made Easy with Low Code

Fraunhofer IPK provides open source connectivity and validation for connectivity. This enables even older production plants to become fit for Industry 4.0.

Open Source for Cyber-Physical Systems from Fraunhofer IPK: CPS Connector & CPS Validation Adapter

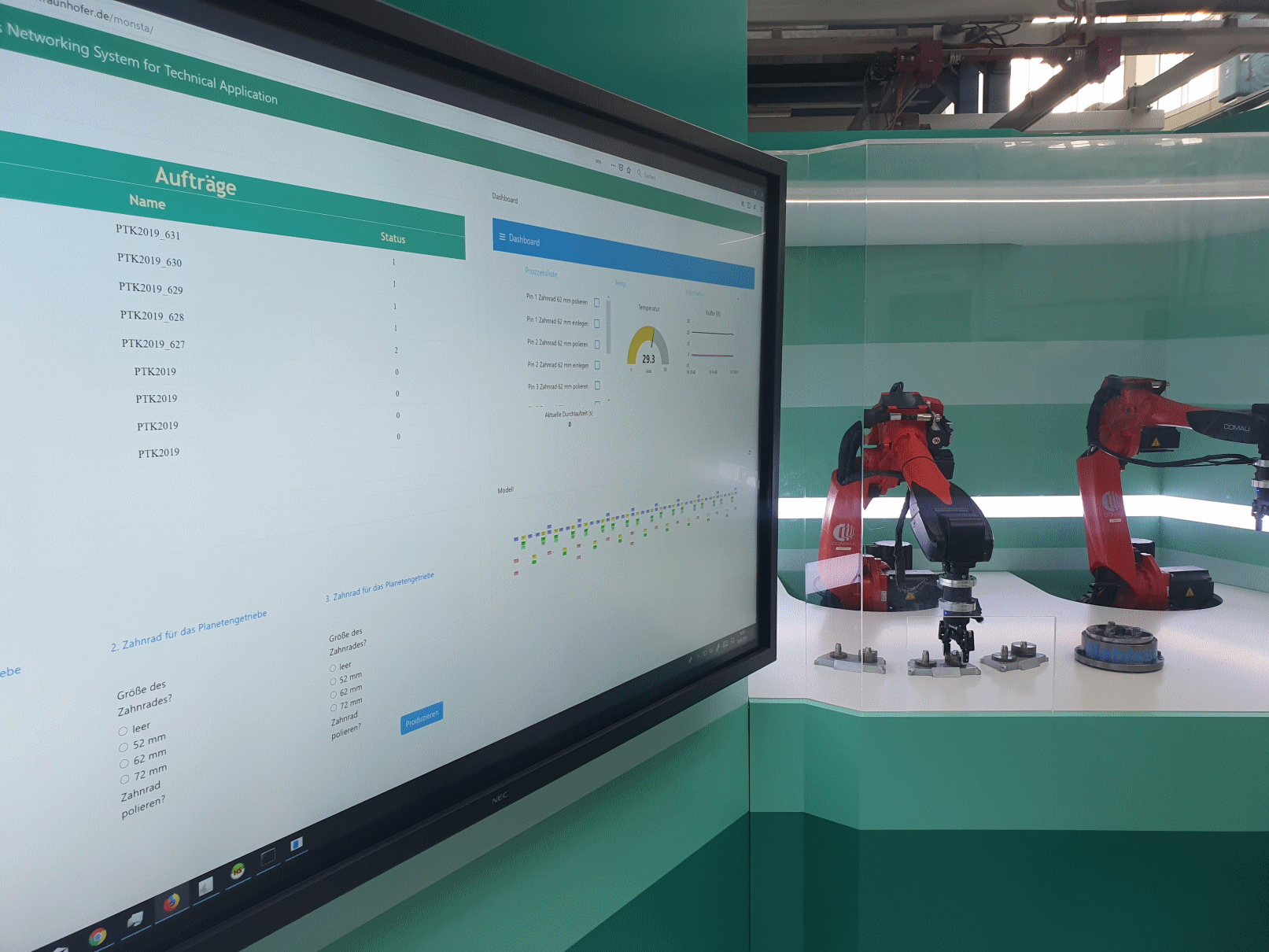

In the age of digitalization and the Industrial IoT, it is becoming increasingly important for machines in a production system to communicate with each other in an automated manner. With the CPS connector and CPS validation adapter, Fraunhofer IPK provides two essential components for production systems in Industry 4.0.

Connecting made easy with Low Code

Communication between machines at the level of production facilities in Industry 4.0 is an essential factor for optimizing the entire production process. If machines are intended to communicate with each other semi-autonomously, an open, networked infrastructure to which existing technologies can be connected is a prerequisite. The associated demand for high levels of networking often acts as a barrier to decision-makers. However, machines and systems can be transferred to a new "control world" and integrated into the existing IT infrastructure and processes with manageable effort.

The open and platform-independent communication standard OPC-UA acts as a base for industrial automation applications. It allows communication between different systems and components in a network and thus ensures optimal interoperability. For example, different manufacturers' machines can communicate with each other. Due to its high flexibility and scalability, OPC-UA is also well prepared for future requirements.

Fraunhofer IPK offers two solutions based on OPC-UA: the CPS connector and the CPS validation adapter. These are a combination of components from the control environment that consist of mechanical and electronic parts − so-called cyber-physical systems (CPS). Together, these components are capable of exchanging and coordinating information to ensure the best possible production.

CPS Connector

Using the CPS connector, individual machines can be quickly integrated into an OPC-UA infrastructure. This is particularly interesting for older machines. A connector for cyber-physical systems enables communication between physical and digital system components. It is an essential component of Industry 4.0 and ensures that machines, sensors and other devices can communicate and cooperate with each other. The system also makes it possible to collect and analyze data from various sources in order to increase productivity and improve efficiency.

CPS Validation Adapter

Having a validation adapter for cyber-physical systems enables validation and test functions within the system cluster. In order to do this, the specific requirements of the particular system or a particular component are considered. In a nutshell, the validation and test functions of the system are fulfilled by interconnecting the building blocks and ensuring consistent and reliable communication between the components.

These Open Source solutions enable small and medium-sized enterprises in particular to invest in Industry 4.0 quickly and cost-effectively. By integrating them into existing IT infrastructures and processes, machines and systems can be transferred into a new "control world". The simple connection and test function for virtual commissioning of legacy machines via OPC Unified Architecture connectors allows results to be transferred more quickly and implementations to be carried out more securely.

One application example is the "Industry 4.0 Suitcase", which enables small and medium-sized companies to digitize quickly and cost-effectively.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology