The transition to electric mobility is a multifaceted challenge for the automotive industry, primarily characterized by the urgent need to efficiently route a substantial number of cables and electrical components throughout various vehicle systems. This complex task requires not only meticulous organization, but also the intricate handling of numerous flexible elements, each with its own unique specifications and requirements. The traditional approach of manually laying cables and assembling connectors, while historically reliable, has proven to be increasingly time consuming and costly in the face of modern production demands.

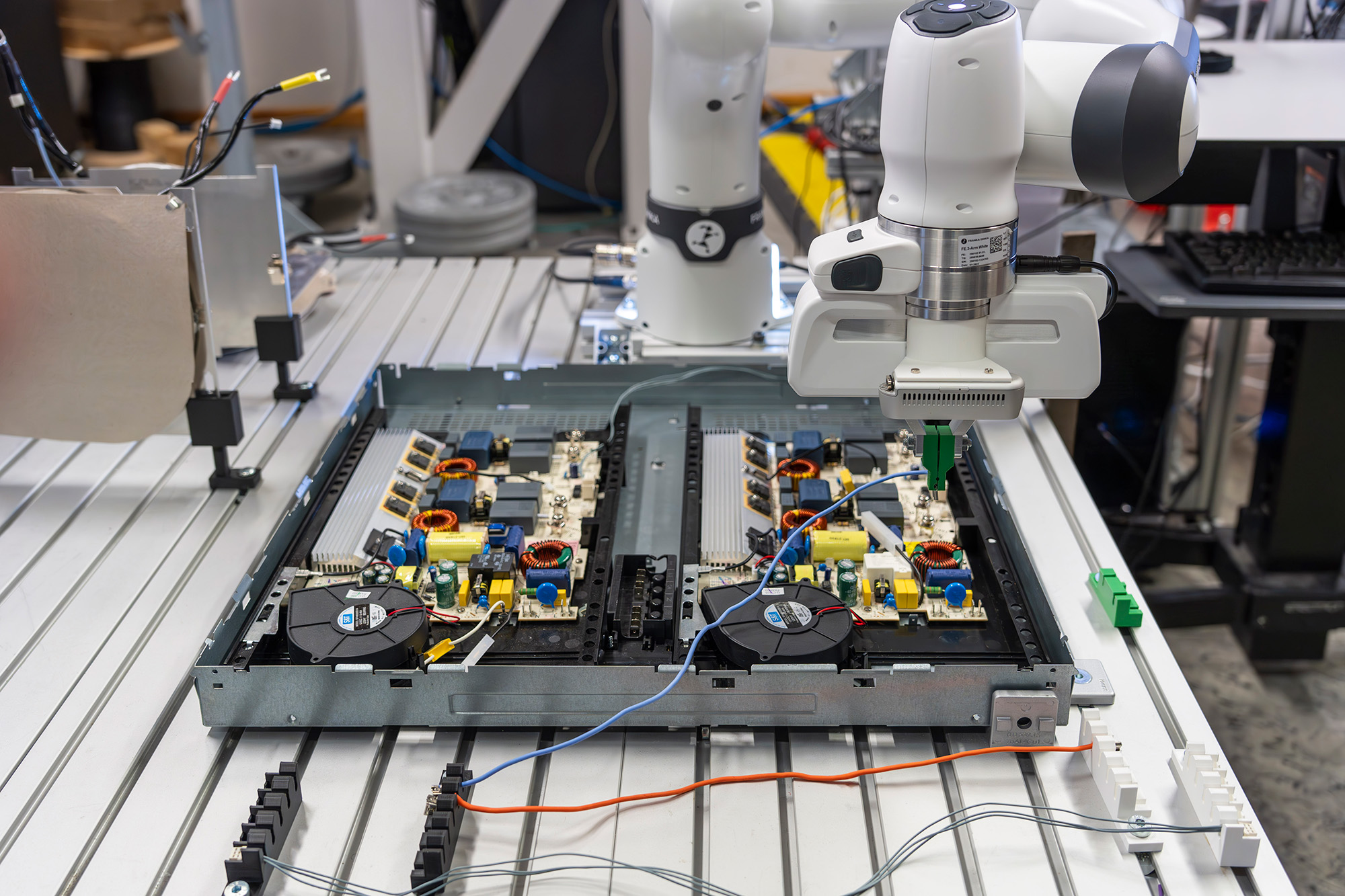

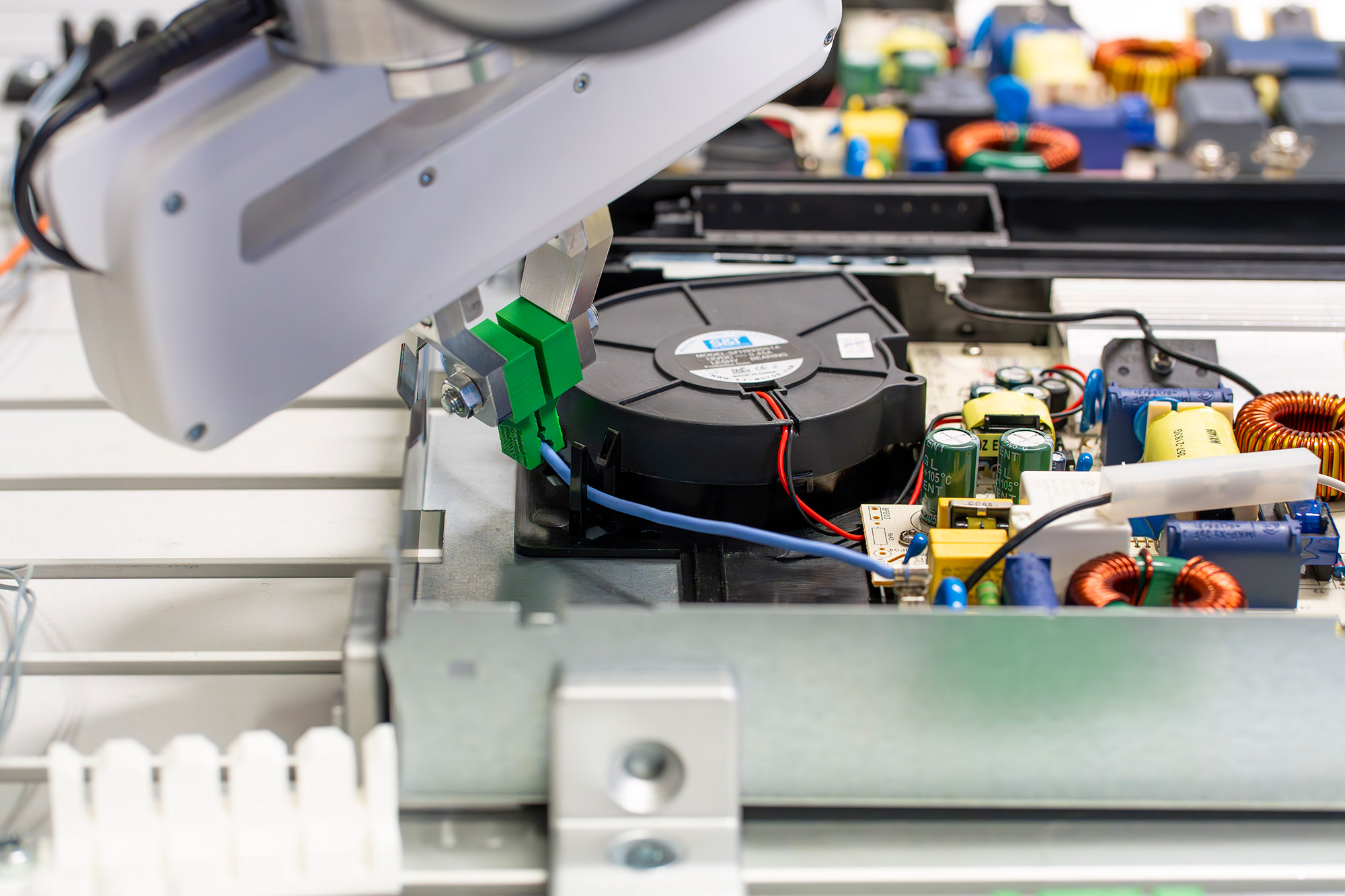

Recognizing these challenges, Fraunhofer Institute for Production Systems and Design Technology (IPK) is at the forefront of developing innovative solutions tailored specifically for robotic automation in this critical aspect of the automotive sector. Central to our approach is the integration of advanced technologies, including state-of-the-art force sensors and high-resolution cameras. Combined with a sophisticated intelligent control system, these technologies enable robots to emulate human-like capabilities - in particular the ability to sense and interact with cables as they would in manual handling and assembly processes.

Increased safety and efficiency through the use of robotic assembly technology

- Reducing repetitive and strenuous tasks. By reducing tiring activities, we not only improve safety in the workplace, but also increase operational efficiency throughout the production line.

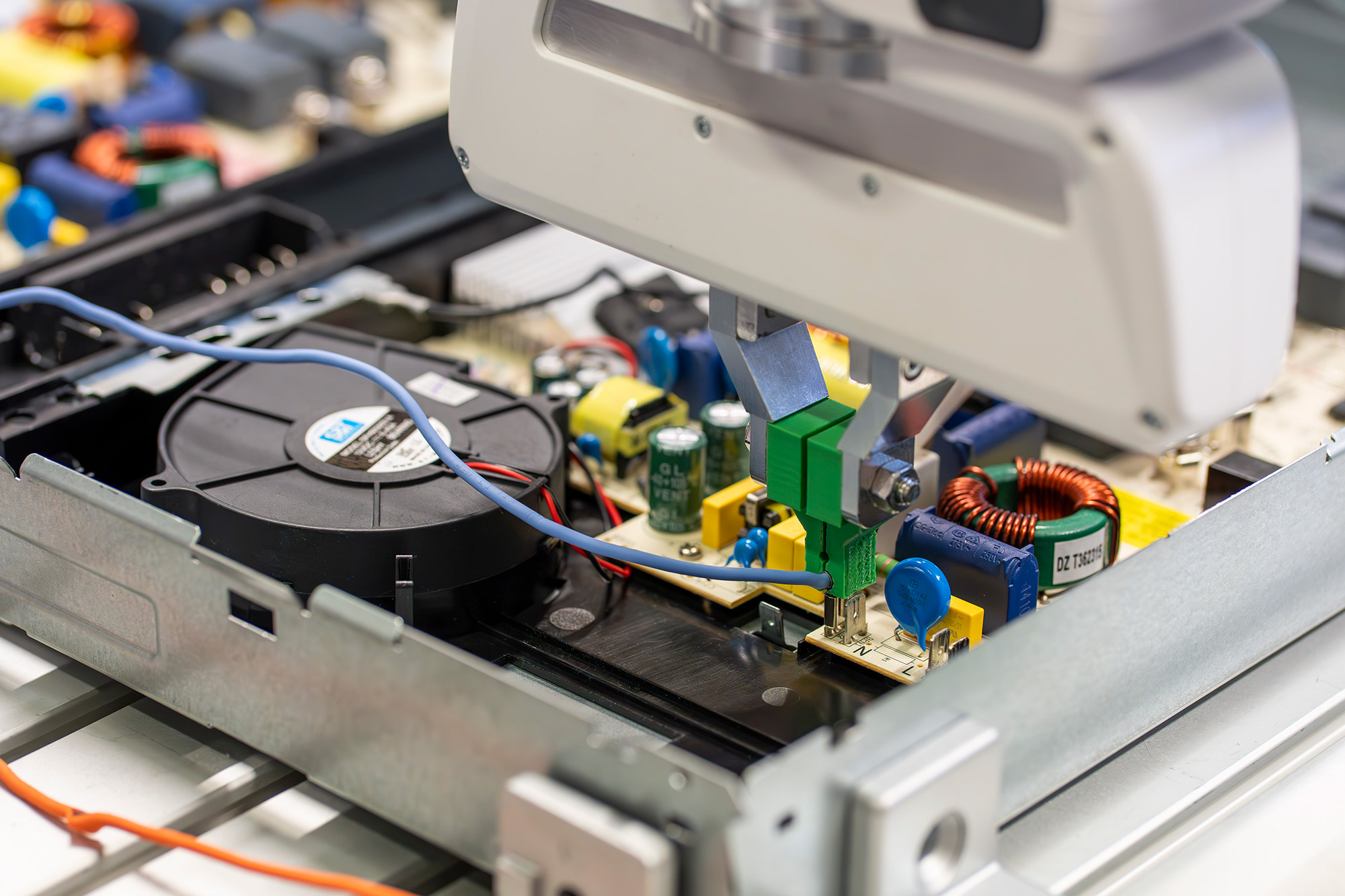

- Robotic systems can react dynamically and in real time to deviations or unpredictable behavior of components. This responsiveness is crucial for the smooth running of automated tasks with high variability, as it enables the robots not only to adapt efficiently but also to maintain a high level of precision throughout the entire assembly process.

- Irregularities can be detected by using recorded images and force signals. This proactive approach ensures both the integrity of the assembly process and the overall quality of the end product.

To achieve these ambitious goals, we work with industry partners to thoroughly analyze existing manual processes. Our specialized laboratories provide a platform for evaluating the technical feasibility of automation solutions and ensure that each innovation is not only theoretically feasible but can also be practically implemented in production environments. In addition, we provide comprehensive support for the seamless integration of these state-of-the-art automation technologies into existing production systems.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology