mobiLAB-4D

Mobile Measuring System for 4D Quality Control of Implant Surfaces in the Synchrotron

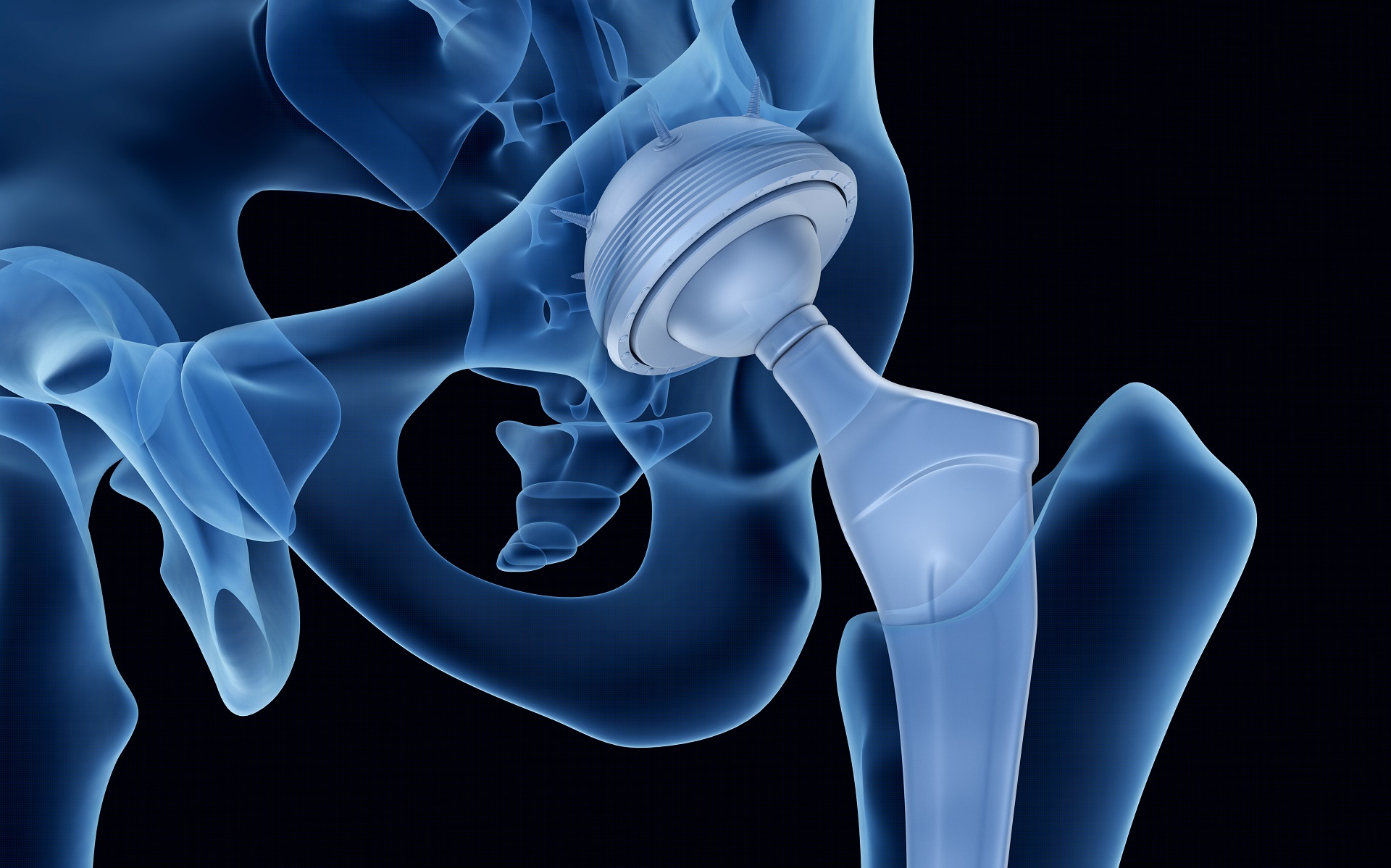

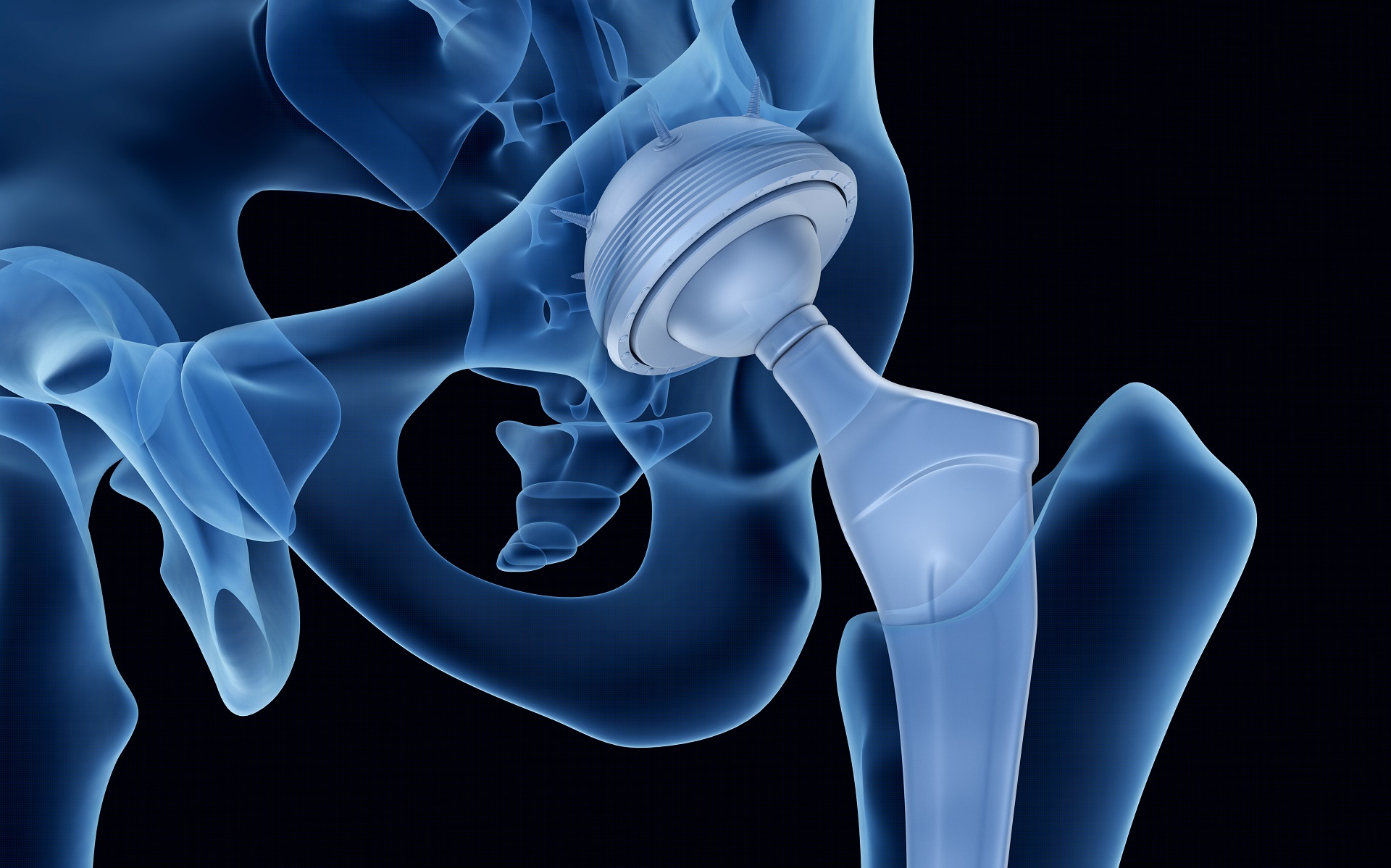

The requirements regarding implant materials are becoming ever greater due to the increasing number of implantations and the higher expected age of patients. However, the effects of the surface structure of implants on clinical complications such as infections or lack of osseointegration have not been conclusively investigated. In particular, the role of nanoparticles or microparticles released from implants into surrounding tissues is the subject of current research and development, as well as regulatory innovations related to risk assessment.

Local exposure to metallic abrasion and corrosion products is a known problem in dental prosthetics. This can lead to increased local inflammation or hypersensitivity reactions. Inflammation of the surrounding tissue (peri-implantitis) and loss of quality of the peri-implant bone (osteolysis) may occur, and osteolysis can lead to premature implant failure. Against this background, four clinically relevant topics are addressed in this project:

- Nanoparticle release

- Toxicological risk assessment

- Insufficient osseointegration

- Peri-implantitis

The overarching goal of this project is to significantly reduce potential complications after implant placement. To this end, novel implant surfaces are being developed and their biocompatibility is being tested in preclinical trials. At Fraunhofer IPK, we are developing a transport unit for organ-on-a-chip systems and a measurement chamber for time-resolved measurement in the synchrotron.

Although the project is primarily focused on dental implants, the results are also transferable to other titanium-based implants, such as hip and knee implants. In this context, the development of novel implant surfaces in combination with meaningful preclinical in vitro assessment can serve as a model for future regulatory processes.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology