Clean and Efficient

Sparks fly, lightnings flash, particles swirl around – electrical discharge machining (EDM) is probably the most spectacular manufacturing process in production technology. With the aid of a generator, a voltage is applied between two electrodes in a non-conductive liquid, a so-called dielectric. As a result, sparks are generated between two materials. The tool and workpiece electrodes do not touch each other and their distance, the so-called working gap, is just 100 micrometers. This corresponds to the width of a human hair. Such noncontact melting allows extremely fine machining of surface structures of metals.

The material removal process, which was discovered by the Soviet Lazarenko couple in 1943, is used in dentistry, among other fields. For example, electrical discharge machining is used to manufacture precision-fit abutments that are screwed into the jaw as connecting elements for implants. EDM also allows very hard materials to be precisely machined and individually adapted, which is particularly important in dental technology: If crowns do not fit, bacteria can accumulate there and cause inflammations.

While machining processes such as drilling and milling are likely to be familiar to every hobby craftsman, few are aware of the key role that material removal processes play in the manufacture of high-precision components in many industrial applications. Examples of micro-holes produced by EDM range from cooling air holes in turbine components, fuel injection systems, gas nozzles and control valves in automotive engineering to thread guides and spinning nozzles in the textile industry. In its main areas of application, tool and die making, aerospace and medical technology, electrical discharge machining is usually used as the last work step before components are cleaned.

The process poses some challenges: Each spark generates gas bubbles and particles that float around in the dielectric and pose risks of short circuits and arc discharges. These discharges not only entail additional control steps or retraction movements, but can also inflict damage on the final component surfaces due to burned spots. The dirtier the working gap, the more unstable the process becomes and the more productivity drops. Cleanliness is therefore key, even in EDM.

In order to eliminate removal products, the gap must be continuously flushed. In internal flushing, which is well established, a non-conductive liquid is forced into the working gap at high pressure. In the process, particles and gas bubbles are flushed out vertically. However, higher pressure comes with the risk of lateral discharges and instabilities within the microbores. The consequence: shape deviations and crooked bores.

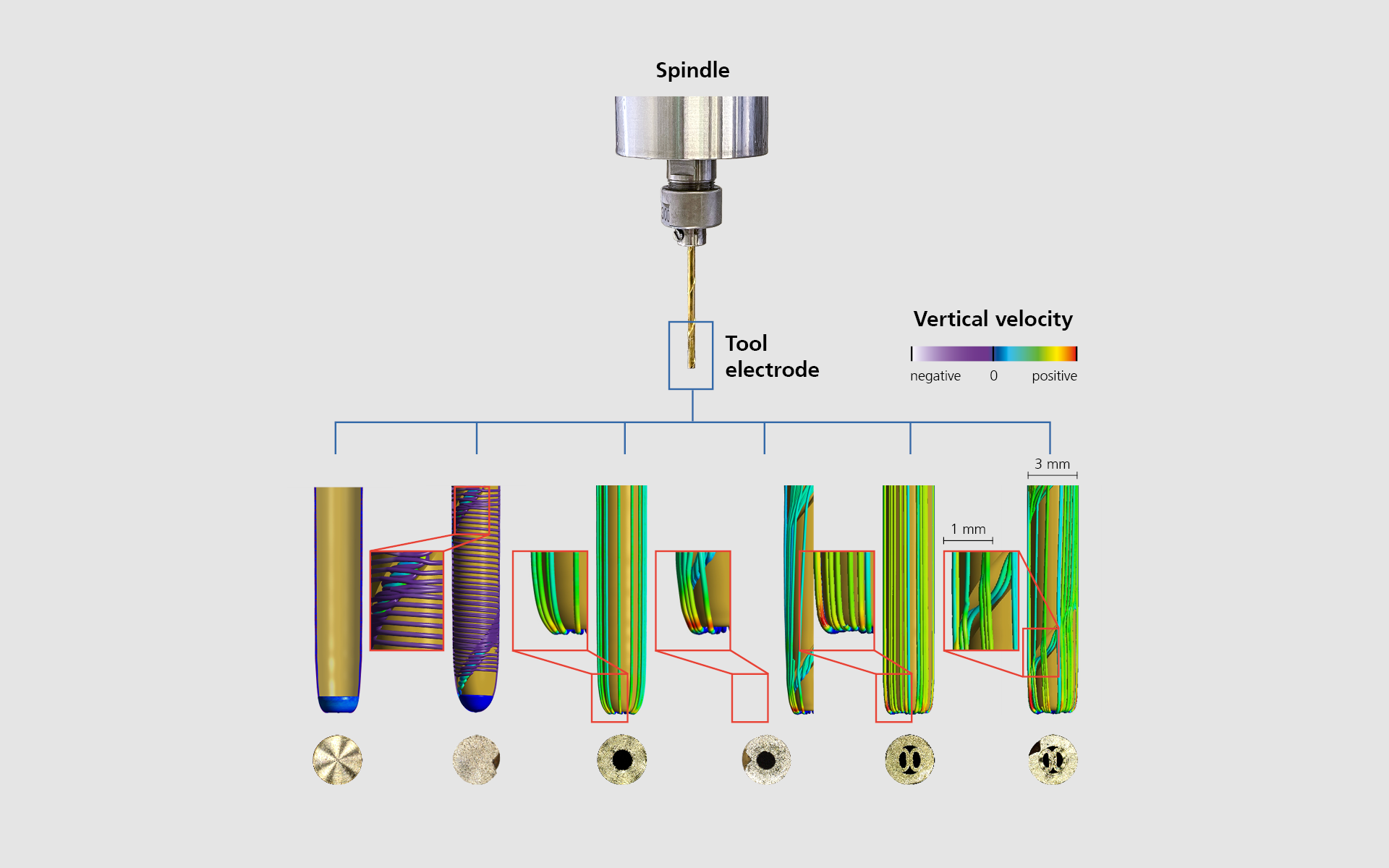

To meet these highly complex and constantly growing challenges in EDM, auxiliary equipment, tool electrodes and technologies for alternative dielectrics are being developed at IWF of TU Berlin. One example is the insertion of external flushing channels into the lateral surfaces of cylindrical tool electrodes. For this purpose, a special CNC lathe was used to mill a helical groove into the tool electrode, which spirals around a brass shaft. This helical channel creates an escape route for gas bubbles and particles. If a dielectric is now forced through the gap at high pressure, the particles are no longer discharged vertically via the shortest path, but are guided specifically through the outer channels. This reduces the risk of lateral discharges and inaccurate drilling.

In a basic research project funded by the German Research Foundation (DFG), a fundamental understanding of the fluid dynamic processes in the working gap is to be developed. The practical research problem is that the gap measures less than 0.1 millimeters, making it extremely small and difficult to see. Detailed optical investigations of the flushing conditions are therefore hardly possible. However, within the framework of signal analyses in which process signals of voltage and current are recorded, conclusions can be drawn about the discharges – and thus about how effective the evacuation of the removal products is.

In contrast, fluid simulations provide unrestricted temporal and spatial insights into the highly complex dynamics of EDM. By means of a statistical model, it was possible to identify a fluid-mechanical operating point that defines the combination of rotational speed and flushing pressure required for optimum performance of the helical groove.

This prevents the removal products from simply leaving the bore vertically due to excessive flushing pressure, regardless of the helical groove. With the appropriate combination of rotational speed and flushing pressure, it can be demonstrated that parts of the ablation particles are pulled into the helical groove by local negative pressures, regardless of the modeled discharge location, and leave the bore in this way. The extension of the model to include gas bubbles confirms known observations that the rising gas bubbles cause the removal particles to float on their phase boundary and thus significantly affect the evacuation of the working gap.

By combining classical experimental drilling tests with sophisticated classifications of the signal characteristics and, last but not least, with the most advanced numerical models, productivity increases in the field of drilling EDM can be achieved with external flushing channels. If you flush properly, you end up with clean results.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology