Pesquisa e Desenvolvimento

Research and Development

At the beginning of the millennium, the only way for the Brazilian economy to go was up. Between 2002 and 2011, its gross domestic product (GDP) grew fivefold, from US$ 508 billion to US$ 2600 billion. Since then, the world’s ninth-largest economy has suffered major setbacks: Due in part to several political crises and the corona pandemic, GDP shrank by almost one third to what is currently approx. US$ 1800 billion.

One area with considerable potential for improvement is the country’s capacity for innovation. The Brazilian economy is very reliant on raw material exports, primarily of soy, coffee, meat, and similar products. These products certainly generate a huge turnover. In the first decade of the new millennium, they allowed the Brazilian economy to achieve impressive growth rates. However, since the figures were also underpinned by high oil prices and social programs, representatives from leading Brazilian industrial companies were already pushing for a restructuring of the Brazilian economy at the time. Their intention was to transition toward greater value creation, particularly in the technological sectors of the economy, which appeared essential for sustainable economic growth.

High R&D demand

This initiative was overdue: Industrial sectors which manufacture technical products are weakly positioned in Brazil. Where high technology and electronic products are concerned, Brazil is dependent on imports. Furthermore, with the exception of a few global players such as the cosmetics group Natura & Co and the aircraft manufacturer Embraer S.A., the Brazilian industry is not very innovative. Quite to the contrary, research and development are viewed more as a cost than an investment, because returns appear uncertain. As a result, there is virtually no culture of innovation in industry.

To make matters worse, application-oriented research outside of industry is not well developed. Brazil certainly features robust basic research, and academic indicators have also improved over the last two decades. But with just a few exceptions, universities are not equipped for industry-oriented research. There are hardly any non-university research institutions that conduct research with or for industry. Essentially, it is only international corporations which perform research and development – and usually entirely internally, coordinated from headquarters outside of the country and with a focus on »tropicalization« – the adaptation of products to local conditions.

Innovation culture from the drawing board

These shortcomings prompted CEOs of the country’s largest industrial companies to call for a national initiative aimed at introducing technology and innovation in Brazilian industry. The goal was to strengthen the competitiveness of Brazilian companies in a globalized economy. With the Brazilian Ministry of Science, Technology, Innovation and Communications (MCTIC) and the Ministry of Development, Industry and Foreign Trade (MDIC), the initiative was able to gain important political supporters as well as a strong financial partner, the Brazilian Development Bank BNDES.

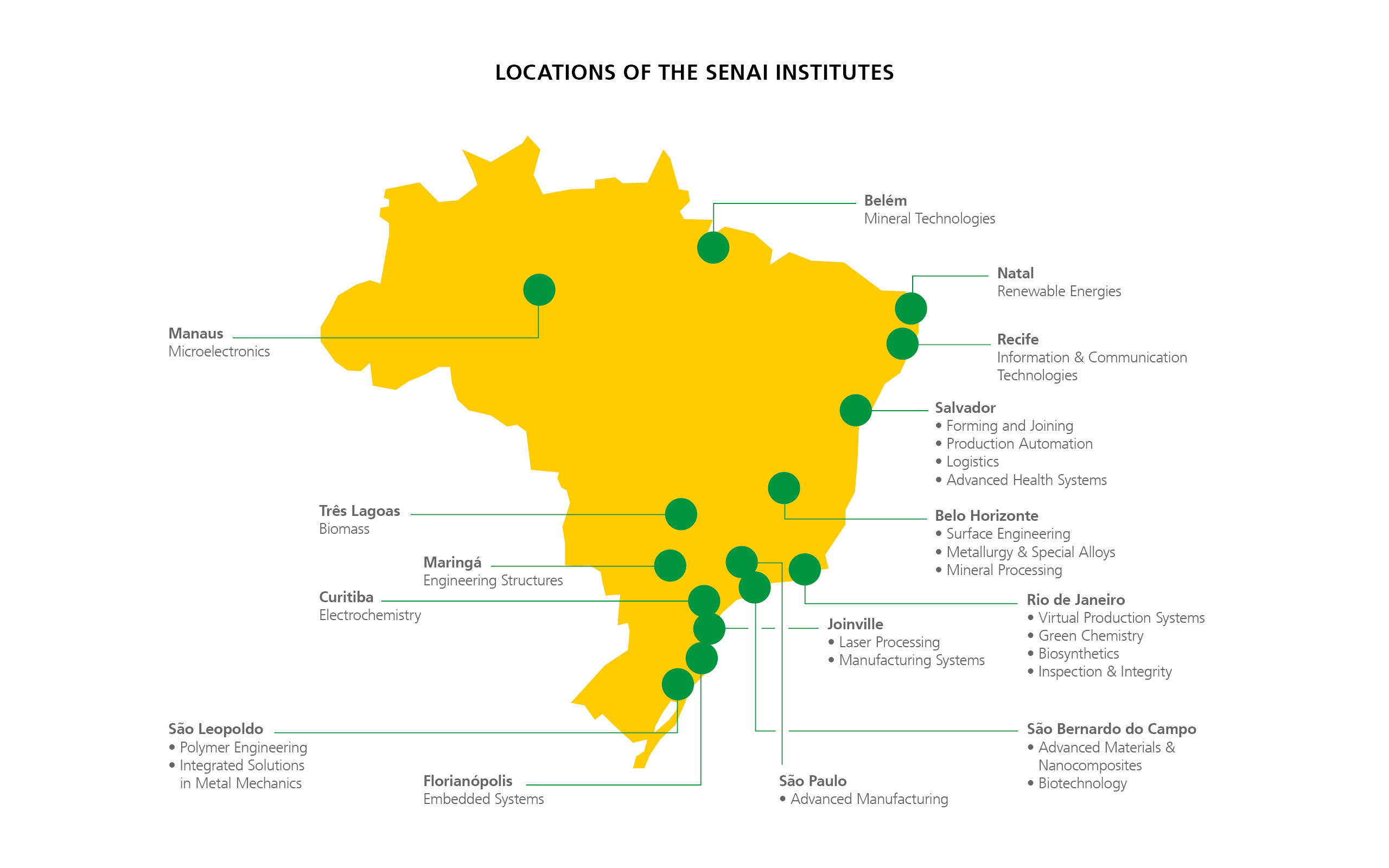

Thanks to this network, the Brazilian National Confederation of Industry (CNI) was subsequently able to commission its subordinate National Service for Industrial Training (SENAI) with establishing a network of 25 innovation institutes (in Portuguese Instituto SENAI de Inovação, abbreviated ISI) that would bring R&D initiatives to local industries. The institutes were to face a number of challenges. On the one hand, they would need to gain an understanding of the entrepreneurial requirements of industry and translate these into technological solutions. At the same time, they would have to communicate with industry in a language it understood, act in an agile manner, and adhere to project schedules and delivery deadlines in order to build industry confidence in R&D providers.

For SENAI, establishing such facilities for applied research was a new task. The organization had provided technological services in the past, such as metrological support and technical advice. But the organization with around 28,000 employees at various locations throughout Brazil had little experience in technological development and innovation.

SENAI’s headquarters in Brasília therefore searched for international partners who would be able to support its ambitious strategy. After benchmarking organizations for applied research worldwide, SENAI decided to seek a strategic partnership with the Massachusetts Institute of Technology (MIT) and the Fraunhofer-Gesellschaft. While MIT was charged with accompanying research, SENAI chose Fraunhofer IPK as its partner for the planning and practical implementation of the envisioned national R&D network. Two arguments spoke in favor of the Berlin-based institute: Apart from its own long-standing experience in applied research, its tried and tested methods and references from the field of corporate management for the strategic planning of innovation systems were particularly compelling.

Structured establishment of 25 institutes

In the summer of 2012, work on establishing the 25 institutes commenced, in some cases entirely from the ground up. The initial focus was on creating business plans for each institute. Researchers from Fraunhofer IPK chose a participatory approach, in which the strategies were developed in a series of on-site workshops alongside the institute managers. This approach proved highly compatible with Brazilian work culture. It resulted not only in professional business plans for the main investor BNDES, but also an initial transfer of knowledge, and the parties involved developed a common understanding of their own business strategy.

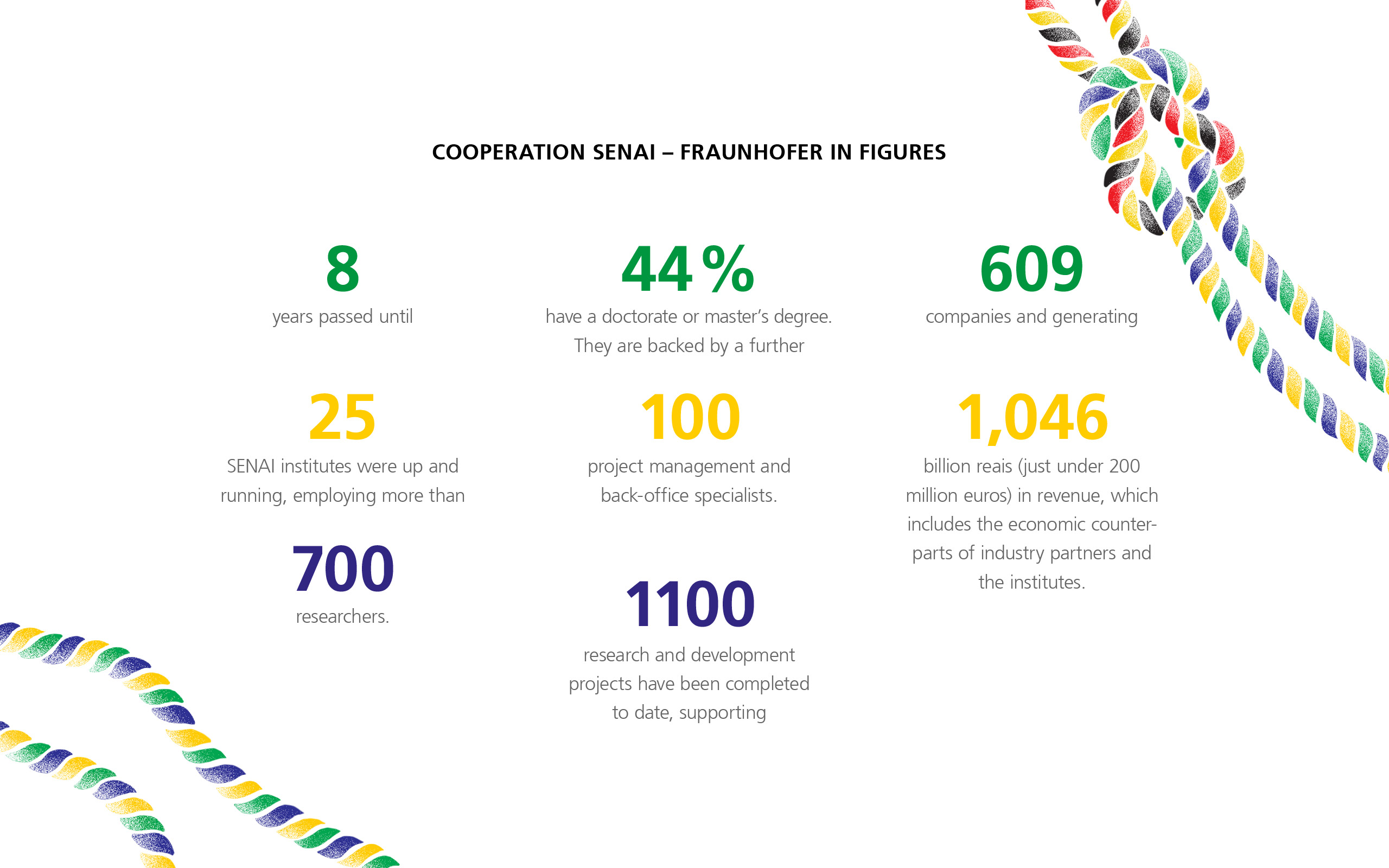

In this initial collaboration phase with SENAI, Fraunhofer IPK succeeded in proving itself to be a reliable cooperation partner. In mid-2013, the consulting contract was expanded, and an initial five-year framework agreement entered into effect, which was extended until 2020. This marked the beginning of a second project phase in which scientists from Fraunhofer IPK assisted with the actual implementation of the 25 institutes by designing suitable management and support processes. On the one hand, the aim was to retain the agile start-up character of the institutes at the beginning of the initiative, while simultaneously underpinning the constant growth and necessary elaboration of organizational structures as well as the continuous professionalization of the institutes and network as a whole.

Maturity level auditing

The first two project phases culminated in the development of a comprehensive evaluation system in the third phase. For this purpose, two sets of methods were developed at Fraunhofer IPK. The »Management Audit« evaluates performance and maturity where the strategy and management of the SENAI innovation institutes are concerned in order to continuously derive measures for their further strategic development and coordinate them with SENAI management at the regional and national levels.

Complementing this, the second set of methods deals with the assessment of the SENAI institutes' technological performance. »We developed a ›Technology Assessment‹ and a subsequent ›Technology Dialogue‹ to pursue the goal of strengthening professional contacts between the various SENAI institutes and the respective ›sister institute‹ on the Fraunhofer side. The aim is to initiate collaborative projects in the future«, explains Fraunhofer IPK’s Fabian Hecklau. As deputy project manager, he is responsible for developing the Technology Assessment.

In the meantime, the project team has handed over the management maturity auditing of the innovation institutes to SENAI headquarters and equipped the responsible experts there with methodological guidelines, tools, and templates, as well as a series of training courses. Fraunhofer IPK continues to be responsible for evaluating the technological maturity of the institutes. In this role, the Berlin institute acts as a supplier of methodologies and a hub within the Fraunhofer-Gesellschaft for integrating the respective technological counterpart and suitable technology experts within the Fraunhofer network for each SENAI institute. Following in the footsteps of the Fraunhofer institutes, each SENAI innovation institute also focuses on a clearly defined technological and research field – across industries and with a mandate for the national market.

Outlook: ESCalate SENAI on four levels

The strategic partnership between Fraunhofer IPK and SENAI is in the meantime entering its ninth year. During this time, it has created an active research network in Brazil. Moreover, the 26th innovation institute was implemented by SENAI itself. Fraunhofer and SENAI are currently taking their collaboration to a whole new level. A new framework agreement signed in 2020 carrying the promising name »ESCalate SENAI – Excellence, Sustainability, Cooperation« will run until the end of 2025.

This follow-up project connects Fraunhofer IPK to the SENAI institutes on four levels: At the level of the individual innovation institute, the evaluation of technological maturity will be continuously pursued. At the level of the overall ISI network, Fraunhofer IPK experts will be providing targeted training and coaching units on strategy, organization and management methods for the innovation institutes, the regional departments in the federal states, as well as the SENAI headquarters, if they have identified a corresponding need for these measures in their regular management evaluations. In this manner, management competency is developed throughout the network as required in order to further support its professionalization and growth.

»At the national level, work is being done to strategically position SENAI within the Brazilian innovation system,« project member Florian Kidschun states. He develops impact analyses that underscore the new research network’s value for Brazilian industry and society. Lastly, R&D collaborations are being driven forward at the international level – not exclusively, but also in conjunction with the partner institutes on the Fraunhofer end. A wide range of corresponding joint market development measures have already been implemented, for example to provide holistic support for German automotive manufacturers with production sites in Brazil, i.e. »from both sides of the Atlantic«, where digitally networked production is concerned.

Tabbed contents

SENAI Innovation Institute for Laser Processing

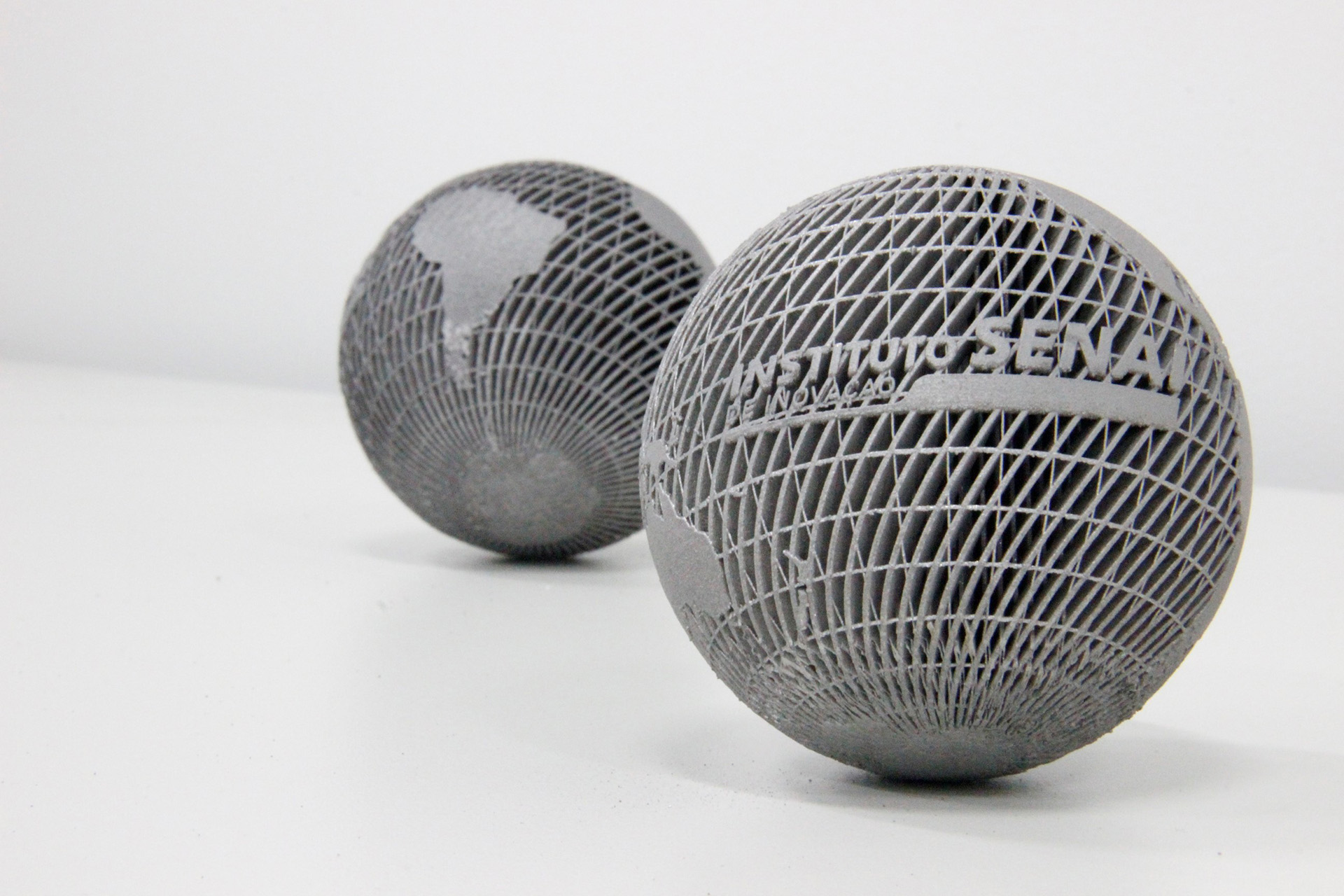

One example of a SENAI institute that was created as part of the project is the ISI for Laser Processing. It is the first institute concerned with laser processing in Latin America and addresses additive laser manufacturing, laser surface treatment, and laser welding and cutting. The institute maintains close cooperation with Fraunhofer IPK, for example through joint research projects.

FERA project

The FERA consortia project is developing additive manufacturing technologies to improve the competitiveness of Brazilian tool manufacturers in this sector. Its topics are based on needs of the local automotive and tooling industry: semi-automated additive repair of stamping tools and additive manufacturing of tools with complex geometries, of fixtures and spare parts. »Our contribution includes automated laser metal deposition processes to repair tools for car bodies and structural components, as well as a market analysis and trainings on additive technologies,« reports Dr. David Domingos from Fraunhofer IPK, who is driving the R&D cooperation between SENAI and Fraunhofer.

Health research at SENAI

Medical and pharmaceutical topics are the focus of research at the SENAI Innovation Institute for Advanced Health Systems and the Institute for Green Chemistry. The ISI for Advanced Health Systems in Salvador, Bahia, addresses a wide range of topics from the development of vaccines, adjuvants, biological medicines, cell and gene therapy products, diagnostic kits and medical devices to bioprospecting studies, biological and diagnostic tests, clinical studies and regulatory processes. ISI for Green Chemistry in Rio de Janeiro creates industrial solutions using alternative techniques and renewable raw materials. The research aim is to generate more efficient and lower-cost products and processes that reduce or eliminate the use and generation of substances that are harmful to health and environment.

SENAI Molecular Biology Network

The two institutes are collaborating in the SENAI Molecular Biology Network, which was established to combat the COVID-19 pandemic in Brazil. The network is taking emergency action to provide molecular diagnostic services for SARS-CoV-2. In the medium and long term, it also aims to help industry establish new methods, products and processes related to applied biotechnology with different industrial sectors.

Currently, in addition to performing a high number of PCR tests, the Molecular Biology Network is working on topics such as designing new SARS-CoV-2 signaling molecules, detecting viruses in drinking water and wastewater, and new approaches to using sample pools in COVID-19 diagnostics.

You might also be interested in:

- More Articles on Health and Medicine

- International Cooperations

- Strategic Planning of Applied Research Institutes in Brazil (SENAI) (innovationssysteme.fraunhofer.de)

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology