The term free abrasive cutting is used to describe several surface finishing processes. The process creates irregular relative motion between the workpiece and the abrasive, resulting in the removal of chips from the workpiece surface. Depending on the abrasive or lapping medium used, the process is referred to as vibratory finishing or lapping.

Stream finishing is a particularly efficient variant of free abrasive cutting and, due to the high flexibility of the setting parameters (angle, immersion depth, container speed, workpiece speed), allows the machining of any complex component geometry. Surfaces and edges can be targeted and processed with maximum efficiency. This leads to very consistent, reproducible results with short process times, low tool wear and excellent automation capability. The process can be precisely matched to any material and any initial surface finish.

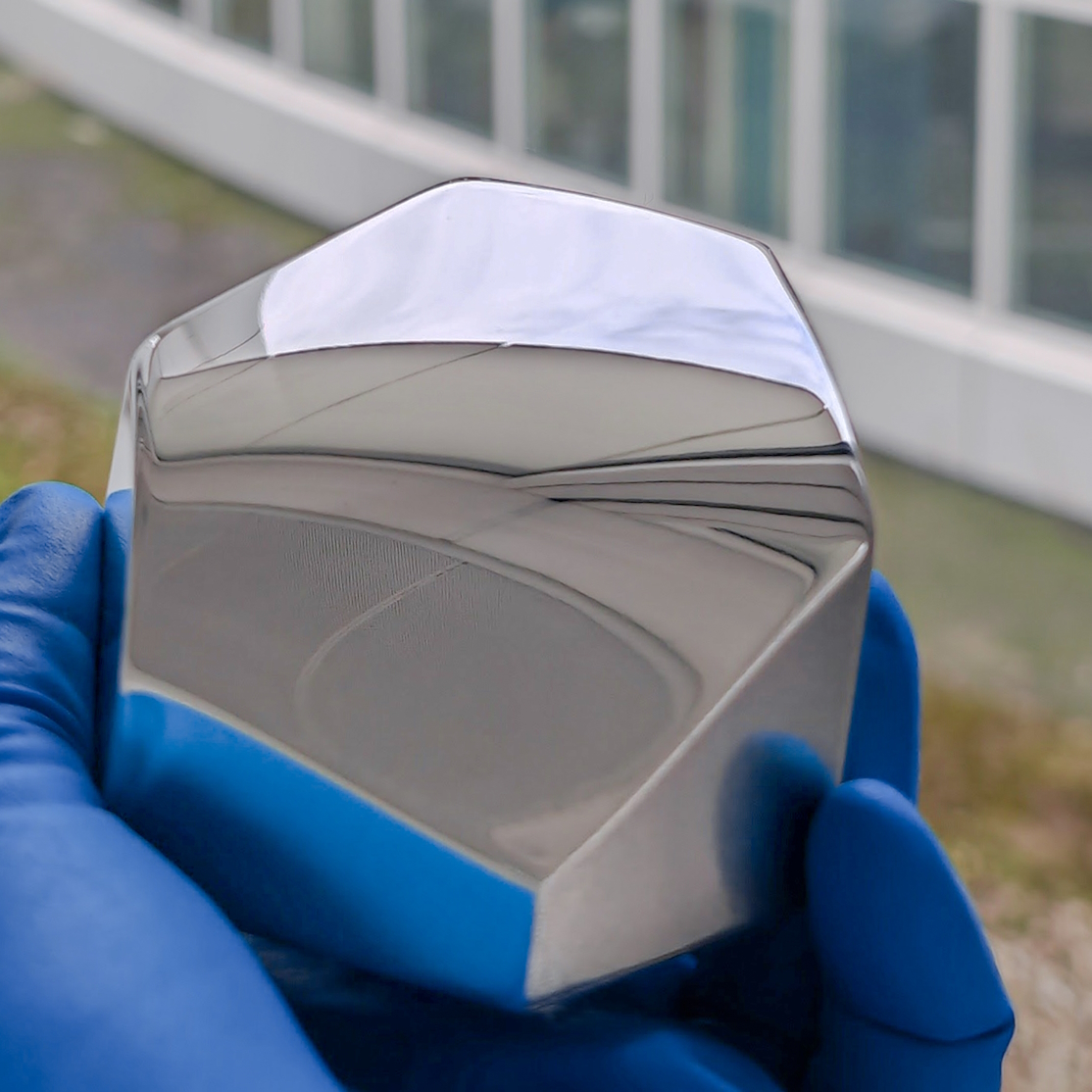

Stream finishing: revolutionary surface finishing for additively manufactured parts

We achieve mirror-smooth surfaces with a multi-stage process strategy.

Automatic workpiece loading makes the systems suitable for cycle-bound line production, such as deburring, rounding and polishing camshafts in the automotive industry. Depending on the requirement profile, the systems are pre-equipped for automatic loading or optionally equipped with integrated automatic loading.

By integrating the machining strategy developed at Fraunhofer IPK into the production process, consistent and high quality results can be expected. This not only improves the aesthetics, but also the performance of the components by minimizing surface defects that can lead to fatigue fractures.

This technological development is a key advantage of additive manufacturing, making it possible to increase the performance of components while maintaining strict quality standards. Short cycle times for mass production can be achieved thanks to high process speeds and good automation capabilities.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology