Quality monitoring and assurance in additive manufacturing

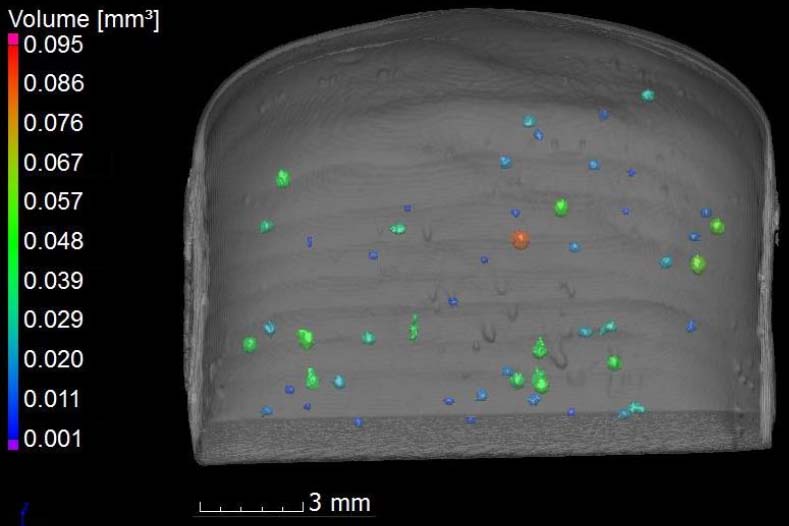

Stable processes and optimized quality management are prerequisites for the integration and use of additive technologies in industrial production. Reliable statements about the mechanical properties of the manufactured components are just as much a part of this as intelligent monitoring and documentation strategies for processes and machines in powder bed and deposition welding processes.

In practice, quality control of manufactured components often takes place after the build-up process. This is complex and expensive. We develop solutions to monitor relevant influencing factors already during the additive process and use state-of-the-art testing methods and sensor technology for this purpose. All in all, we work with you to establish a comprehensive quality management strategy along the entire process chain, thus enabling you to achieve robust additive series production.

Fraunhofer Institute for Production Systems and Design Technology

Fraunhofer Institute for Production Systems and Design Technology